Eastern and Western Saws Part II

It’s hard to say who came up with the first saws for woodworkers with hardened teeth. I first saw it in the USA in a catalogue maybe two decades ago where the description said, “Lasts five times longer than conventional saws!” This was a Spear and Jackson catalogue. Since then came the stupid names we all put up with and started using, names like Predator, Venom, Pirhana, Barracuda Fatmax and then all the worse ‘Professional’!” Did the Japanese pull stroke saws start the trend of hard-point teeth or no? Hard to say. Back in the early days of strategising Japanese marketing of hand tools, their saws were traditional and non-hardened teeth. Problem was they were expensive and needed saw sharpening skills. The steepness of the angles forming the teeth meant the need for an additional bevel at the point of the teeth to add strength to the weak and fractious point. Some makers and marketers refer to this as the ‘new triple-bevel technology‘.

So we now start seeing sales marketers refer to the ordinary sharpening of saw teeth, be that Asian saws working on the pull stroke or westerners at a push, describing teeth as “dual ground teeth, “double ground”, high-frequency hardened teeth, and many more together with, how about this for selling plastic, “ProTouch grip with three times more elastomer for maximum soft feel.” Or what about this, a “High swarf removal woodsaw.” And then, “Blade is water-based lacquered to provide four times better rust protection than standard lacquer. I mean what idiots do Irwin think they are dealing with here? Or, “Lacquered coating to reduce friction and prevent corrosion.” Just how much corrosion takes place on a hard-point disposable saw that is intended to last for no more than 30 hours work max? So you buy into these £15-30 saws in packs of two or three (and that should tell you something) every few months. At least that is what I would have to do because that is how long a so-called “Professional” hardpoint saw would last me in my daily use of saws and the savings soon become non-saving and ever-more costly. And please don’t write in as one writer did to tell me he’d (I’m guessing the gender here) rather be doing woodworking than sharpening a saw every few minutes. That’s a gross exaggeration by the uninitiated and that’s not what happens! Sharpening saws is woodworking! Sharpening is as much a part of woodworking as cutting the wood with the tools you sharpen. And why would someone find sharpening a plane and a chisel acceptable and not the saw? Hmm. . .

The Asian pull-strokes are now made and sold so cheaply that they put their own masters out of business for the main part. Western makers put themselves out of business because for many decades they seemed only capable of producing inferior grade saws. This was pure arrogance on the part of those claiming Superior in their branding and such. This prefaced the import of western-style saws from Asian producers and at one time people were informed of the country of origin because it was on the product packaging and product. Something shifted and often we have no idea where a tool is made. Some independent makers in the west realised that all they needed to do to find a small corner of the market was to what western mass-makers were too arrogant to do and that was to improve their products. I think that it is fair to say that Stanley and Record have continued to decline in much of what they produce. Or perhaps it’s fairer to say, well, they haven’t improved much at all. I don’t think that Stanley ever produced the kind of quality saws say Spear and Jackson once produced in their 1800 early 1900 days. The more recent introduction of hard-points is little more than three decades old. These saws, western or eastern, are all made in this anonymous place called overseas or abroad or import. I am ashamed to say that few saws made in Britain since the 1950sever came from the manufacturers in good condition and ready to cut from the packaging they came in. That has changed but only marginally. I have proven that I can take almost any western saw, old or new, and in less than a few minutes make it cut like a premium version. I can also alter the pitch to change aggression levels and take the same saw to make it a ripcut or crosscut in under four minutes. I don’t do that because dedicated saws are the efficient way to go.

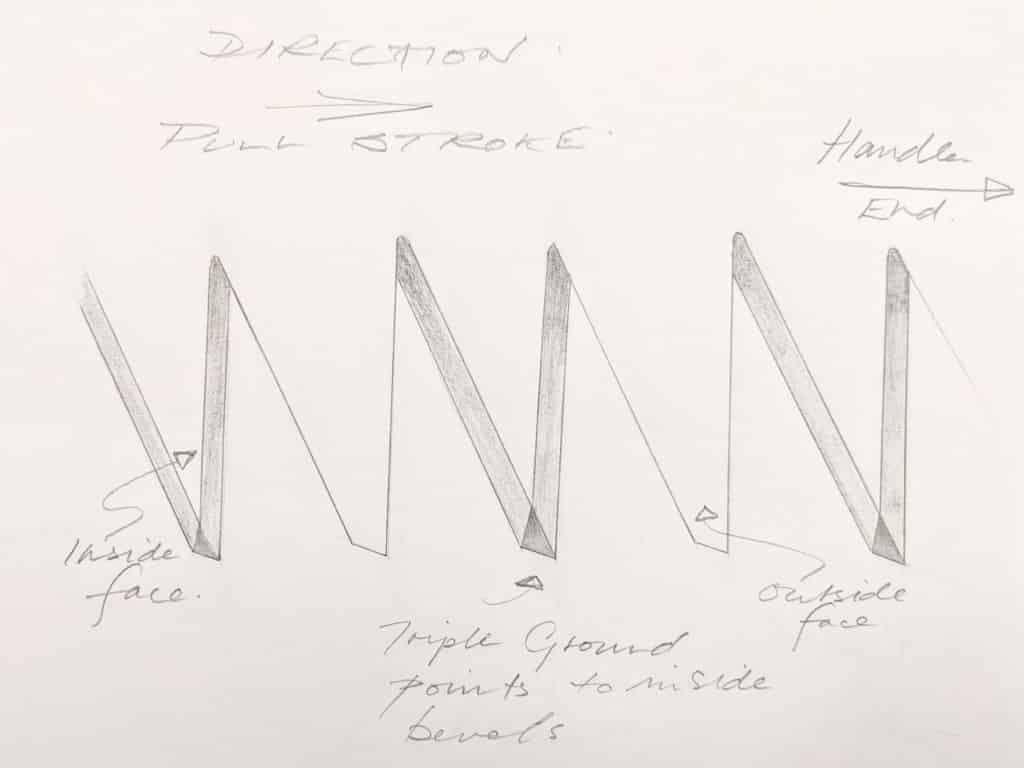

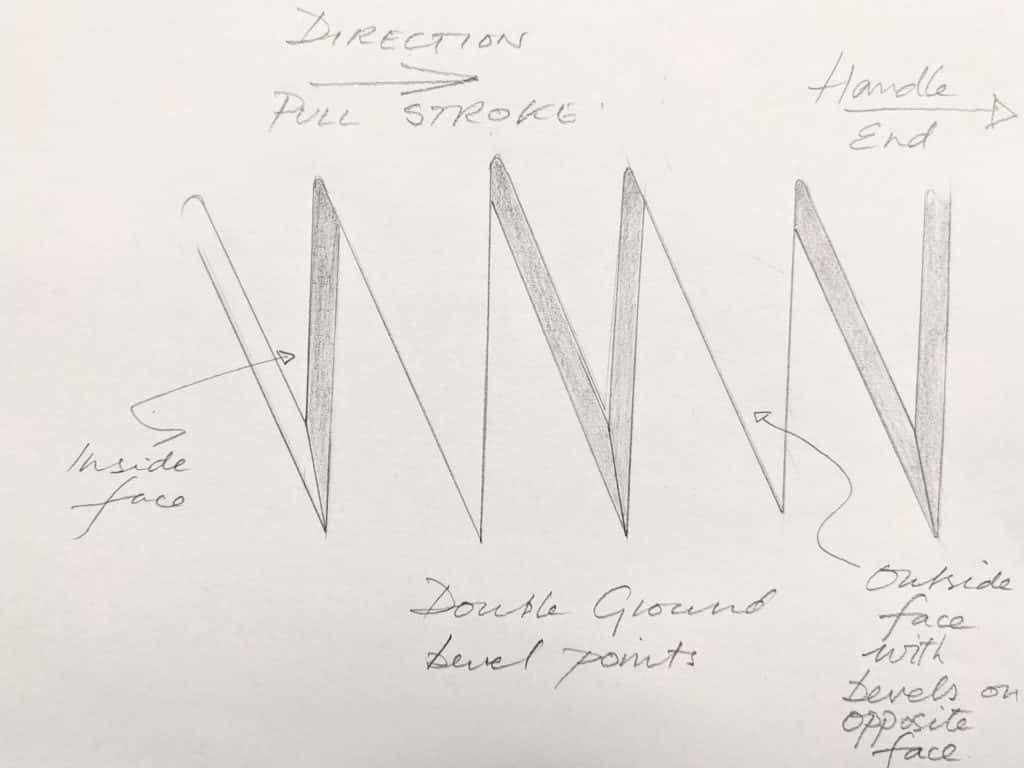

Asian saws have a steep pitch to the front and back of the teeth. The files used to sharpen them are very steep-sided and short in length. The crosscut saws actually cut on the return push stroke too but much less aggressively. This is exactly the same as western crosscuts, by the way. The reason Asian saws have a triple ground bevel to each tooth is because the angle of pitch necessitated the extra bottom bevel to strengthen what would technically be a non-viable point. That’s not to say that it would not cut, just that the pinnacle point at that meeting point of the two facets would break off in a matter of strokes and so render it less viable for longer-term cutting. The bottom bevel, now the third grind, strengthens the cutting point on crosscuts. The newer technique of producing impulse-hardened teeth exponentially opened the market to the world because it costs almost nothing to do. Indeed, the saws now totally produced by machine came to closely match those made by the Eastern masters in traditional Japanese saw making but in a matter of minutes not hours. We are just a few years away from seeing all pull-stoke saws being made by machine as will ultimately happen with western saws as there is only a handful of western saw makers making saws in the West. As a boy living in Stockport, I could have walked into a dozen workshops offering saw sharpening services. Not so today!

The new thing here in the US is the marketing scheme MADE IN THE USA(with global materials). The “with global materials” is in a tiny font impossible to read from arms reach. Sometimes instead of made it will read assembled or built. I still have no idea what that means. I guess all the parts are made in china, sent to the midwest and somebody inserts a screw into the handle to “make” it or “assemble” it. I guess Ikea furniture is technically made in the USA as well, by the purchaser.

You are right about the hard point blades, I first bought a Vaughan flush cutting saw in the early 1990s and they were bragging about these new hardened teeth on this pull saw, blade made in japan.

Well I’m certainly better informed about this apparently rather devisive subject about eastern v western saws. I’m going to stick with trying to master the sharpening and use of my western saws. I still have a way to go but thanks to Paul, for I am getting there.

Somewhat harsh language in places I think Paul;

“I mean what idiots do Irwin think they are dealing with here?”

They don’t think they are dealing with “idiots”, but they are dealing with the uninformed. I was one too, until just a few years ago. And most folk buying this stuff won’t be using them the amount you are, so they will last a “fair” amount of time.

“stupid names we all put up with”

“Stupid”… They’re just names. The commercial world makes these necessary for marketing, but they’re not “stupid”

And “putting up with… and the option is?

“buy into these £20-30 saws every few months.”

I’ve just looked on the Screwfix site… Out of 40 saws listed, the dearest is £18, the next dearest is £16, and 29 of them are less than £10

Don’t get me wrong, I share your basic philosophy, and thanks to finding your videos some years ago, (and being one of the very lucky folk able to attend a 9 day course at Penrhyn Castle), I follow your path and way of doing things… But I suspect the vast majority of these saws are sold to working tradesfolk in the construction industry. Time is money and at the prices these saws cost it’s more efficient to replace the saw… Sharpening a saw on site is not practical. Setting up to do it means it would take longer than the “few minutes” you take.

That disposable saws are not good for the environment is probably indisputable however!

Keep up the good work, but remember that, for the most part, you are preaching to the converted here!

Regards,

Matt

Thanks, Matt. I did change the price down £15 before you commented because I realised in my speed writing to ‘get it down on paper’ I may have said too high and forgot to self-correct. I don’t mind using a sledgehammer to crack the nut though, I think that it is important enough to me to make sure someone at least gives a shout here and there.

Yes, often exaggeration promotes understanding, I agree. I too am one of the convinced and converted, but I think we’re up against the toughest opponent of all here: Reality! We’ve got so used to take any opportunity to save time and money that we can’t escape from that way of life, it seems. Even though most of us deep in our hearts can feel a wish and a need to live a slower life filled with high quality in what we say, what we do, what we eat and how we live.

And I can see that much more clearly now than I could 40 years ago – I too was caught by the idea of cheap, quick and smart – and so I’ve made my contribute to the holy growth of so and so many percent in economic growth. Of course I’ve had my share of troubles and mostly good times, too. But I never felt such a general happiness like I do today, where I don’t have to make money for others. It’s so good to have the time to think before doing when I do things, woodworking included. I think we all need to create a new reality – with more responsibility. Towards our selves, our families, our communities, our earth. And that’s why we ought to use a saw or any other tool for a lifetime instead of a month or just a year.

That said, I must admit that it can be hard for me to let go of those habits of the past: I recently bought a saw to cut still useful wood, possibly with invisible nails. I payed what equals 3 £!!! It cut’s fantastic, no doubt. And I could’nt help it. But was it nessecary? Now that I’ve learned to sharpen saw?

Well the seed is sown – let’s pass these thoughts on to each and all, then perhaps the next generation(s) will be able to harvest the fruits of a world inhabited by people living much more sustainable, than my generation did…

I enjoyed this, Ajens. You know, I have a couple of hard-point throwaways that I use and don’t throw away. I use these on chipboard and pallet wood and generally for my outdoor work in the garden where wood is likely to pick up grit that will scratch the plate and dull the teeth. The one I use costs £14 plus shipping so £17.50. It’s not this type that bothers me so much as I use this type differently though still thoughtfully and carefully. It’s the work at the workbench that troubles me the most. It is such a delight to sharpen a saw and keep sharpening something that will, as in my case, last you for 55 years and twice that in reality.

Thanks for responding Paul.

We all know what it’s like to knee jerk sometimes!

Matt

To Matt Sims and Paul: I tend to be a bit harsh when it comes to the American public. When I read “I mean what idiots do Irwin think they are dealing with here?”, I immediately thought about the huge population of stupid people here. But Matt, I probably should tone that down some. It’s not that they are stupid (though some are, but not most), it’s that they are gullible. Marketing has gotten very sophisticated and clever. People see words like “hardpoint”, “long-lasting”, “glides through wood” and they see a picture of a man dressed in construction clothes and having a three-day growth of beard and holding the saw and they buy it on the hope (or trust?) that it will perform. These are the same people that buy crap that claims to make their knees work like an 18 your old’s knees.

The other side of this is the whole throw-away culture. I see the next generation (20- and 30-somethings) totally buying into throw-away items, from saws to cars. It really irks me, but I have to try to remember what I was like at that age. Fortunately with age comes some knowledge of the realities of this world, and I can now be more responsible.

BTW, I don’t believe construction workers are the primary buyers of those horrible throw-away saws. When was the last time anyone saw a construction worker cut something with a hand saw? No, the primary buyers are home owners – and even then, most of them use circ saws or jigsaws. Maybe the most frequent buyers are those who aspire to get into woodworking and don’t yet know enough about the equipment and just need to buy a cheap saw to get started. Either way, …

“Lasts five times longer than conventional saws!”

Considering that re-sharpenable saws last several hundred years, that is quite an impressive feat.

Can’t help but snicker when I read things like ‘maintenance free’ batteries or bearings. It’s simply marketing speak for ‘can’t be maintained – throw away and buy new!’ when normally you would add water to the battery or clean and re-lube the bearings. And as you’ve mentioned before, it’s exploiting people’s weaknesses (inability to sharpen or maintain, or even laziness and incompetence) and selling it as a strongpoint: “it’s simply un-economical to maintain, sir, your time is more valuable than that! Throw away and buy a new one, it’s the smart thing do!” Absolves people from a guilty conscience of lacking simple basic skills.

” ‘Professional’!”

That goes two ways… I’d be thinking that I’m not a professional and thus aren’t allowed to own and use such professional tools. The girl at the checkout might ask to see my professional license and would refuse the sale if I had to admit that I’m, alas, not qualified to own professional tools? “Sorry sir, but we can’t allow such professional tools in the hands of the general public.”

Marketing speak works two ways, after all. ‘New and improved!’ often has me wondering whether they were selling me old & lousy stuff in the past.

“Lacquered coating to reduce friction ”

What, no Teflon (PTFE) coating?! What incompetent, backward cheapskate fools, I would want nothing to do with them and their inferior products.

But perhaps the time is ripe for you to market your very own ‘Paul Sellers Rag-in-a-can oiler’ (as seen on TV!) and put it out there on the shelves. ‘We use only the finest rags and premium grade oils. Our cans are ergonomically designed to comfortably fit in the palm of your hand and are made from recycled steel, helping you to help the environment!” Add a photo of yourself on the label, friendly smiling with your name under it. Perhaps add, “If friction is getting you down, don’t panic, Paul Sellers will get you up again!’ Don’t rest until on every woodworker’s shelves there’s at least one can (you could offer variously scented versions for different moods or seasons?) with your face on, gently and approvingly smiling.

Perhaps hint at other possible uses of your product. I’ll not get too specific, but of racing cyclist Mario Cippolini it was said he used the same lubrication for ‘chain, coiffure and coitus!’ Now *that* is 3-in-one oil!

Please don’t take my above post in the wrong vein. Re-reading it, the last bit (selling the rag-in-a-can oiler) might come across not the way it was intended. Was written in a humorous sense, saying that a very basic product that’s easy to make oneself would probably sell like hot-cakes when surrounded with the proper marketese speak and imagery.

Forget Teflon (PTFE) or water-based lacquers on the blade of the saw… a bit of oil will do the same and better….

I just couldn’t help but snicker at the thought of a ‘real’, original store-bought rag-in-a-can sitting on the bench, with a picture of yourself on it. Myself, I’d be too cheap to buy an original Paul Sellers rag-in-a-can…. I’d roll my own. In fact, have rolled 3 of them (two for woodworking, one in the shed for the gardening tools). But on re-reading, I should’ve worded things a bit less in a way that could come across as an attack on you. Always hard to convey the proper ‘tone of voice’ in writing.

Oh no, Nemo, not at all. All’s good with me as I thought it most interesting and humourous. Thank you!

thought I’d point out that niwaki in the UK sell a handmade ryoba saw that’s very good, it’s made from Aogami Blue Paper steel and very good quality and can be sharpened as well, but sharpening one is very challenging.

There is often a sentiment to “blame” the manufacturers for their “stupid” names and slogans or their ridiculous products, but truth be told it, is the consumers that are driving this. I work for a consumer goods company and can tell you with extreme confidence that every product name, every performance claim, every product design, is directly geared towards giving the consumer exactly what they are asking for. That’s what sells.

Hardpoint saws are prevalent for one reason and one reason only, that is what the consumers want to buy. You can make the argument that is because consumers are uneducated (and it would be true), but who is responsible to educate consumers? The manufacturers certainly cannot afford to educate you beyond what you need to know to make a purchase decision, and most consumers are rightly skeptical of any real “education” from a manufacturer (the exception being “infomerical” shoppers, typically not the most sophisticated decision makers).

To make it worse, the internet has spawned a whole class of “experts” that post a video “review” of a product and get paid affiliate marketing dollars (either directly or indirectly) by the manufacturer or the retailer. But there is no real way to vet the expertise being passed on, and the barriers to entry are so low that almost anyone with a cell phone can become an instant expert. Once again, those so called experts who tell the consumers what they “want” to hear are the most successful.

No, I do not blame the product manufacturers. The products they make and sell are not the cause, they are a symptom of the larger issue of a society that values instant gratification over hard work and an education system that fails to teach true life skills.

Sorry for the rant.

It’s true that’s it’s naive to blame manufacturers entirely and consumer shifts in demand do steer supply. But it’s also naive to dismiss any thoughts of manufacturers creating demand through creative supply.

I’d rather stay in control anyway: if I need a sharp saw I can sharpen one to a fashion and not be reliant on available stock, delivery times, delivery slots or spare cash.

Since rag in a can *love it* was mentioned and given my recent consumption of vinyl gloves (in a bucket in my garage) I suppose a video of a “Gloves in a Tube” Hammer is out of the question.

Good marketing on the part of a manufacturer can definitely influence demand, but only up to a point. In the end, the consumer votes with his wallet and always has the last say. Hardpoint saws sell because they are cheap and easy, and that’s what most people want (present company excepted, of course!).

We must remember too that all those old tools on EBay aren’t woodworkers selling you their tools to help you out. Most of them are junk dealers who buy out estates of the deceased for a song or go around to your widows after you are dead and by your old horde of tools on the cheap and put them on EBay for as much as the market will bare and their marketers are us when we encourage others to buy them. I know people like that and i am sure you do too and they make a pretty good living doing it. Its just business and nothing else and they only do it because you are willing to buy it. They don’t need to tell you all about how nice they are because someone is telling you to buy it as is and refurbish it. Hey buy a dozen so that you have enough parts to build a workable one.

Supply and demand. If the buyer wants cheap then the manufactures are more then willing to make cheap. Veritas and Lie Nielsen are two manufacturers that are endeavoring to produce quality products and quality costs money. Instead of ranting about the cheapies we need to support the ones making the quality items. If we don’t support them we will get what we deserve … cheap Chinese tools. If you encourage people to by old junk and fix them up then you are contributing to cheap tool manufacturing and denying the quality manufacturers a market and they too will be obliged to go out of business or make cheap. Not only that, the buyer and sellers are catching on and exploiting the used tool market and this old junk is going up in price. Cheap tools are here to stay because the home handy man who uses those tools so infrequently they think they are great. Paul, if you keep encouraging people to buy used and cheap what do you think you are doing to the quality tool market but killing it. I have a Veritas Jack Plane, a Veritas router plane, a Veritas scraper plane, and i got my eye on their Jack Rabbet plane and their Combination plane and their round spoke shave. I don’t have a lot of money, government pensions but i don’t waste money on sea cruises, hotels, entertainment or fine dining either. If you aren’t fine with cheap then support those making fine tools instead of lamenting the cheap. Complaining just causes anxiety, stress, depression and heart attacks, just go and buy a quality tool from a company you like and thank them for still making a quality product and encourage them to keep it up and then tell someone else so they too can support the quality tool market.

I have Veritas router and spokeshave..and I have to agree with you. They are quality products.

But when you say that Paul Sellers is killing Veritas and Lie Nielsen because he is supporting ‘cheap tools’… I strongly disagree.

Paul is lifting woodworking on new level(and he is not the only one) . I am sure that Veritas and Lie Nielsen are grateful to Paul and other great woodworkers because they are selling products based on theirs work. And I’m grateful too!

Without Paul I would not have workbench, nor router and spokeshave… On top of that, I wouldn’t have Stanley no.4 and that plane is just fantastic. And the list can go on and on…

Bottom line is… I’m happy that he is supporting second hand and cheaper tools because not all of us can invest in ‘premium’ tools. Veritas and L.N. are happy too! It’s win-win situation!

Wayne, Isn’t there a place for everyone? So many woodworkers I know could never spend £300 on a #4 smoothing plane and especially when it will do no more than an eBay purchase for £20 plus a little TLC. And I mean what I say! All of my inexpensive planes will do everything any of the premium maker’s planes will do and possibly more. Also, Wayne, your choice of the word “cheap”! Mmm, mmm, I know why this is said and could this be a little disingenuous, possibly? Not sure. There is a huge difference between “cheap” and ‘inexpensive‘. Stanley planes are not cheap nor are they necessarily cheaply made. They usually need buyer input which the companies you mention do for the consumer; they add quality finish. But so is the case with Quangsheng, Luban, Juuma, and Woodriver. All are good quality, heavyweight planes from a less expensive stable. If you like heavyweights, which I never ever understand. Clifton, Lie Nielsen, Veritas, all good quality planes weighing in as heavyweight planes. If you or anyone wants to buy them then they are there for the offering, no problem. eBay is not putting these makers out of business but the truth is price can make the tools made prohibitive for the majority. My quest in life is to get people back working wood and not buying into the theory that you get what you pay for. It’s important that people can buy a £25 tool that works just as well as a premium tool often costing ten times as much. My quest too is to get people over their fears of messing up a premium tool. What better saw to learn to sharpen on than a new £25 saw or one found at a flea market or a garage sale. I’ll stick with what I encourage people with. I own all of the above maker’s planes and have them in boxes. The choice between which ones I would sell if times got hard would be easy. Every one of the premium and not so premium heavyweights would be out listed on eBay. That is not to say that there is anything wrong with the engineering quality or the materials used. My Stanleys and Records still whistle and sing in my hands and some of them are indeed after 55 years of daily use. I will finish with this. My Stanley #4 has been with me at my workbench for 116,600 hours. I doubt there are many woodworkers living now who can say such a thing.

Hi Paul, I agree wholeheartedly with your views on advertisers. I often have a rant about their practices. The job is to make products attractive but devious seems almost to be their middle name. My favourite story is about the original Flymo. It hovered over your grass, cutting it but leaving the cuttings, considered a design fault but the marketing men came up with the slogan ‘mow your lawn and mulch it at the same time!’, clever but patently untrue. I only found your site a couple of months Ago having decided to try woodworking at 67 years of age, the first time since grammar school! It has proved to be invaluable and also strangely comforting and calming. Thank you so much. With very best wishes.

It is not about east v west. It is about knowledge and understanding the difference so that the woodworker can make the right decision. Without the candour and honesty of Paul we would all be worse off. So, thank you Paul. I love to learn from you. Your articles are enlightening and I am really enjoying your comprehensive advice and comments.

Hard tooth saws are nothing new.

My Hammacher Schlemmer 1906 catalogue offers saw types with hardened teeth, apparently for hybrid wood/ metal trim, or just so you didn’t have to sharpen.

The Disston D-4m backsaw came in several sizes from 10” to 26” . They could be purchased with any tooth size and were hollow ground to require no set.

The addendum to the offer says “not guaranteed”.

$17.50 a dozen for the 10” size , or about the same as a dozen D-8 panel saws.

There is also a Disston plumbers saw which cut wood on one edge and cast pipe on the other edge. I’m not sure you could call that a woodworker’s tool.

It appears hardened tooth saws didn’t catch on.

No one said that teeth weren’t hardened earlier, Larry, at least that’s not what was meant. All saws were hardened and tempered because the annealing is what made them resharpenable. Some saws were extremely hard and I have had old saws that were uneven in the tempering leaving some teeth that were indeed unsharpenable. On a small scale, some saws were made as you pointed out but the point was more that the emphasis shifted to produce saws with induction hardened teeth on a mass-making scale.

We have a small hobby farm, and I use the hardened tooth “disposable” saws for repairs on fences, cutting the corral boards and other things where the wood is particularly hard, rough and sandy. They work for a while and produce a quality of cut that cows don’t notice.

Also, I started this hobby using the veritas smoothing plane and now I have 3 stanley #4’s from ebay that I have cleaned up, sharpened and used. I am shocked at how much better those are; but I don’t see any chance of cutting into Lee Valley’s sales, they’ve got so much good stuff.

I sold tools for 30yrs in an industrial supply company in Canada and when I started the Chinese stuff was junk and there were good quality saws and planes all over. However over the years I watched the goods cheapen as prices came down. Fortunately I bought my Stanley Profesional saw when they were still up there along with Disston in quality. I have Stanley, Record, Bailey, Footprint planes and there is most definitely a difference in feel and I prefer my Veritas planes. They are pretty much as good as you can get. I am good with that. I think I will stick with my older Stanley handsaws but I have picked up a backsaw and dovetail saw from Lee Valley recently and they are a delight to use. Like most of you out there I have looked for cheaper tools to fit my budget but they are all gone now as I have replaced them with better tools along the way. Good quality sharp hand tools are by far the BEST way to do woodwork. I used to tell my customers that ” there are no cheap tools. what you pay will usually decide how well the tool works and how long it lives”. The advantage to good quality tools is that if you no longer need it or have changed what you are doing, someone else will be quite happy to pay a fair price for it. Cheap tools, not likely. All my tools are old and still are more than capable of doing a days work without breaking a sweat. Younger people on this site are still in the process of learning this. Good luck with that. I am sure Paul would agree that there is NO substitute for quality materials and workmanship.

Hi Paul I’ve enjoyed your info and learnt a lot but I seem to be missing some thing with regards to re-cutting teeth as to what depth the initial saw cut is delivered to the saw blade before filing?

Thanks Warren

The out of the box cut quality of the Eastern saws, especially considering the price, is astounding. I think they are teaching this “old dog” a new trick. My dad made a living with wood and when routers came along, he had no objection to them and rolled them into his kit (though when he passed, he had a collection of chisels larger than anyone I think).

I just put a spiral head on my joiner and planner. Though you could say that sharpening the blades is indeed part of woodwork, but it is not the part I want to be doing (the setup after sharpening is tricky).

The idea is to let each woodworker pick a path that works. A painting is a painting regardless of natural brush, synthetic brush, pallet knife or just your fingers for that matter.

Japanese saws can provide a fresh start for adults who tried to learn with a worn out western saw as kids or young adults. Since it is so different you can approach it without the learned belief that “I can’t use a handsaw, I tried”. I had a couple of worn out (I now know) hand saws when I was young and first married. One day in the late 70’s or early 80’s I was in a hardware store and saw a plastic handled “Japanese pull saw”, the one with the black handle and red plastic wingnut to hold the blade, Shark Saw or something like that. It was inexpensive and I picked it up and brought it home and have been using it for household jobs for decades. I still have it and use it as a utility saw for sawing dowels, flush cutting, and other jobs. I have no doubt that now, if I bought a quality western saw I could learn to use it. But when I got the woodworking bug, I bought medium quality Japanese pull saws. Kind of avoids all those bad associations.

I won’t get into the pull saw bit again, I continue to use hardpoint saws, I prefer what have become”Irwin” Jack saws, although Irwin have added soft plastic on the handle, which is NOT an improvement, makes it difficult to use a loose or “floppy” grip. If you want to know I use that grip for cutting man made boards to increase the kerf width, essential if the air is damp,and useful if you are using the teeth forward. These saws in a 7 tpi version are fine for most construction jobs. if you are careful hand cutting frame and stud work they’ll last a few days, before they get irritating, and they go down the line of rougher and rougher work till you cut em up for scrapers. Buy them in the sales. Buy all of them ! Jack also used to make a really good carcassing saw that I can’ t find any more. What I’m getting at is, that tools are still going down hill even now. It goes with the level of knowledge I suppose, I have seen some extraordinary comments about tools recently, I got into an argument about slotted screws recently, and to follow on, about screwdrivers, the guy had obviously not got the idea that a screwdriver has to fit a screw, told me that hollow ground bits were best ? So it goes.

Hi Paul,

I need some suggestions on recommended saws to look at or look for. Currently I am in need of a back saw or two. I prefer a traditional style handle.

Thanks for your input.

Follow our training vids on common woodworking site here.

I have been fortunate enough to acquire a number of hand saws that are on average a hundred years old. All were dirty and rusty. They cost $0 to $5 apiece, and include 3 Disston #8 and 2 Atkins # 400s. Having one in my hand gives me joy and inspiration.

I’d like to see a demonstration of how to convert a saw from crosscut teeth to rip.

It’s simply a question of sharpening square across instead of at an angle. This video shows much of what’s needed. https://paulsellers.com/knowledge-base/saws-sharpening-refurbishment/

What would your opinion be on making your own saws? It is easy to get the correct steel for the saw plates on Amazon, and there are sources for recycled or newly made saw backs and saw nuts. It seems like it could be a worthwhile project. Thank you for all of your great content!

I do use a throw away saw for chipboard and rough outside work where there is a good chance of dropping the saw onto concrete. I can understand people on building sites doing the same as anything valuable is likely to be stolen. There is also a juvenile culture of having to have the same kit as everyone else in order to be accepted.

I do find it insulting when a manufacturer assumes that I will not buy their product unless it is designed to look like a weapon or has a name which would fire the imagination of an 8 year old.

I don’t have any interest in attacking or destroying wood, or buying products which claim to do that.

There is always a market for premium products. Some people will always buy the most expensive. By encouraging people into hand tool woodwork, a percentage will buy the top price tools. By showing that others can get the same result for a few pounds and a bit of effort, you are merely giving options.

I have to confess to being a bit of a design snob with regards to modern saws. I would readily pay a few pounds more for a saw with a better looking handle. The modern crop of traditional , mass made saws have handles which range from bland blobs to butt Ugley. I bought one but sold it on. I just hated it.

I love western saws but at 70 years old with poor eyesight it is chancy at best. Larger teeth is doable but get above ten and it is iffy at best. So Japanese saws enable me to keep going with a a hobby that is a great way to speed some of my retirement time.

Meant to to say shrapening in above statement.

The most obvious reason for buying a hard point saw that does not need sharpening is the buyer will most likely not have the clamp necessary to hold the saw in position . He may not have a bench with a vice to hold the saw clamp .He may not have a good file to do the sharpening. He may not have saw set pliers . Some people do not have a workshop to keep the bench and vice and saw clamp . Most newcomers in a hardware shop will not even realise they need so much gear to achieve the sharpening in a few minutes from a standing start . They might not know they need some lessons before sharpening a saw .So the saw makers have been merciful to them and given them a chance to cut a piece of wood without all the paraphenalia .

Ah,that’s a new one, a “merciful” saw maker–Hmmm! If we believe that one we are on a slippery slope.If I ever believe anything like that show me the same mercy and take me outside and shoot me. It is funny how many exaggerations were used here to tip the balance of opinion. I personally see saw saw sharpening as an essential skill to woodworking as is making a simple clamp to hold the saw, a workbench and vice to hold the working and to and then also workspace. People wanting to become woodworkers almost always want to learn to sharpen their own tools–all of them.

I wonder how long before we shall be using carbide-tipped hand saws for wood. Hard tips seem to work rather well on circular saw blades.

Hi Paul, and any of you who may have sufficient functioning knowledge to offer an opinion. I am not the world’s most experienced woodworker, but I am meticulous. After having this same debate internally about Eastern vs Western, I have decided that I want to go with Western. This is for a number of reasons, but primarily because having tools where, for me at least, the maintenance of which are just as much part of the pleasure of the process as anything else, and will grow old as I do, is something that is important to me.

So, with that said, I have been looking at purchasing three PAX saws from Thomas Flinn & Co in Sheffield. A dovetail r/c 8″, a Tenon r/c 14″, and a Tenon c/c 12″.

Am I mad? I don’t want to have to buy twice.

Many thanks

Rob Cosman makes a good point in his recent Dovetails By Hand video that I hadn’t considered, about the case for a western saw when it comes to dovetails at least. He says that the western style handle give you much better registration compared to round handled saws (Japanese pull saws, Gents saws). He says that in this instance, the western saw handles make it easier to tell if your hand is titled too much to the left, too much to the right, or that it’s right-on perpendicular. And further, that this effect makes it much easier to develop a muscle memory for performing each type of cut.

Can’t really add much…as 99% of my handsaws are older than I am(67.) Mainly Disstons, some Atkins, and a Richardson & Bros. Mitre boxes also have disston made saws….although Disston never made a mitre box.

Anything finer toothed than a 7…I send out to the sharpening service…the 5s , 6s, and 7s..I can SEE well enough to do the job meself….but, when instead of 2 teeth, it looks like 4 (or more..) time for someone to do the sharpening.

As for the “new” handles? Pick up a pre-1928 Disston & Sons saw at a local yard sale ( just bought a D8 Rip with the “extra hole”) ..Once your hand wraps around those old handles, you just don’t want to let go…let alone sit it back down on the table. Those handles were shaped by workers who knew what a handle should feel like.

I clean, sharpen, and USE those old saws. There was a backsaw, sold at Aldi’s a while back….I cut 4 recycled 2 x 4s…and already had 2 broken teeth on the saw…someone wants to “borrow” one of my saws..I hand the Black& Yellow WORX saw….

Paul. I’m a newcomer. Like many here I suspect in my mid 50ies and rediscovering the joys of making things with my hands after years of working on making more tenuous outputs.

I am looking at saws on eBay. From rough looking things that cost £10 through to named items at £150. I’ve followed your writings and videos on sharpening, so feel able to try at least with the right saw that has its teeth intact. But I’m less clear about dealing with a blade that does not have a perfectly flat plate. Doubts about whether I could fix this takes me towards buying new as I don’t want an expensive tool that I can’t use. Are you able to give any advice on what to look for when buying an old saw with a view to getting a tool that can be worked on (probably learned on too) to get into good condition and then will last me out?

Thanks for all the inspirational output. It’s been a joy to read and watch. I will be in touch again on you blogs. Alan

There re options but for some reason, some people seem reluctant to buy a tool they cannot hold in their hands. I will never buy a tool where the seller says ‘no returns’ and ‘photos form the description’. In every case of return, not many in hundreds of transactions, I have always had my money back and in some cases, eBay themselves have repaid me directly without need to return to the seller.

The photos are very helpful and so to descriptions but don’t forget you can always ask questions or request an added photo too. 95% of my tools, vises, and so on have come from eBay. Most people will look down a saw line for a bend and tell you if it’s straight, but a saw with a slight bend is it really an issue as they can be bent back easily. Kinks in the plate are a different thing, avoid these. A bend need not come out though. Remember the teeth protrude from the plate of the saw so there is a gap between the saw plate and the wood. This gives a little tolerance for steering the saw and progressing into the cut.

That’s really helpful Paul. I think I will pitch in and try buying a few saws at the cheaper end and see what I can do by way of cleaning up and working on my sharpening skills. There seem to be loads of Disston long saws as well as Tyzak tenons. I will dip my toe in and see. Best wishes. Alan

Made in [country name] is already years a scam. It used to mean that it was completely made in that country written on the label.

But I know that already many years there is a loophole in that label and many manufacturers produce all parts in a cheap labour country, ship the parts to their country and after having the assembly label it as being produced in that manufacturers country.

It is a legal loophole, but it trashed the value of the label.