In Praise of Record QR Vises

I have a few different quick-release (QR) vises installed on workbenches here at the workshops. Eleven workbenches replete with 9″ wide vises opening to between 11-15″ in all. Through the years the old Record vises have all worked to a consistently high standard alongside my many Wodens and a really nice Paramo No51 on Hannah’s bench. Other good copy makers to look for from that earlier era are Parkinson, Toga, Rededa, Paramo and Marples, they often go for less money, but they are scarcer. Lesser quality ones are out there, some overpriced and some reflecting the cheaper quality in the price, but be a wary buyer.

The three workbenches I work from in the day-to-day are Woden and Record quick-release versions. I probably would not buy a new copy if I could buy an old version but there is an Eclipse copy that I have used with reasonable functionality. It’s hard to say how long these will last because there is a looseness to the parts that will most likely lead to an excess wear you don’t want in a vise. Irwin Record stretches the truth by a marketing boast as follows: “IRWIN, 133 years of ingenuity and high quality.” when in reality they simply bought the Record name a few years back. If you doubt that these vises are one and the same as the old Records, you’d be right. They are Record in name only. The quality is not the same and the price is up there if it is not the Record-of-old quality: they sell their ‘import’ larger woodworking vises Irwin 52 1/2 ed with QR at up around the £210 mark. Remember. Import vises such as Irwin, Anant, York are of lesser quality even though they look and weigh in as quite heavy replicas, I suggest that you buy with caution. As with most lifetime warranties, the companies rely on 99% of people never making a claim. A one- or three-year warranty is of no real value to someone using a vise an average of an hour or two a week. And what is a ‘lifetime‘ anyway? Watch out for reviews too. One I read said, “Wonderful beast of a vice, really well made and solid engineering. Can’t wait to try it!” Many if not most of the reviews brag on weight alone indicating this to be the main factor for buying the vise which tends to be the norm. Whereas weight is a factor (Newton’s law of motion), there’s more to a good vise than mere mass and the weight issue can be adverse if the metal composures are not equal to the task as wear is the key failure when the metals fail in the mechanisms.

A little history can be revealing. Evolution always tells us things improve with the better educated, the more athletic and of course, with the better engineering –survival of the fittest, if you will, and in some ways, things might. Science gives us so much. Additionally, science gave us things that could be hijacked and pirated — and most things are. The originator of the plastic bags so freely given out almost per item bought in supermarkets for decades are likely at the bottom of the oceans and all places and spaces in between. Science gave us both the bag and the investigations into pollution. `All things considered, improved life for a single species should always be weighed up against its consumerism and world economics against the cost to the remaining life beings. In most cases, one improvement cancels out the sins of the other until they come back to bite us. Read the following for my experience of the latter evolution of the all-metal vise.

Roughly speaking the Record QR is about a hundred years old. I owned a Taiwanese-made quick release 25 years ago that did not copy any make that I knew of that was one of the best I ever owned and used over a longish period. I was happy but then, guess what? A Chinese maker came on the scene to undercut the price of the Taiwanese one by half. Visually, on the outside, they generally all look and feel the same utilitarian way. It’s not until they are actually installed that you can really test the action properly and it is here that you might feel rattles, quivers and shakes you would never have found on those vintage versions once made here in the UK’s Sheffield. Tool-making industry. That Sheffield is all but gone compared to its former years of glory as the steel empire of Europe when the town, permanently covered in the belching smog of the fuller industrial years of steel making, made the vises we relied on for decades and centuries. Everyone went for the second Asian maker in China and the vises sold through distributors in and throughout the USA where everyone was demanding ever lower prices, and so it goes — another and another came and each undercut the former both in price and then, of course, in quality. The problem with this was that with each iteration the quality declined ever so slightly and the really good maker went into some other manufacturing business followed eventually by the others. So it is with progress sometimes. None of the purchasers knew that their version would become the ultimate bad copy until after a year or two of very minimal and part-time use, possibly an hour a week or so, the flaws began to show with the threads in the castings that received the threaded steel tightening bar began wallowing out. The QRs stopped functioning and slipped because the necessary catch on the threads failed to take place; this was the same with Indian copies too. Where most of them are made today we no longer have any idea. This includes the Eclipse and the Irwin Record. If these companies refuse transparency it makes them hard to deal with for their reliability. But mostly it seems to be about creating something that looks the same but isn’t. By the time the part-time user in amateur realms reaches a few hundred hours of use the vises are well out of the warranty period and in most cases, no spare parts will be available because somewhere in the mix the companies sold out to a takeover company with no liability. I have a Record vise that I have been using for 50 years to date and it was old when I bought it.

I think that it is worth saying now that most vises will be imported from Asian factories and some will come with the seller’s name in the casting but side by side you cannot tell the difference between three or four so-called brands because it is the same maker making them. I checked two new ones I bought in yesterday and cannot see any difference between the two. One will cost you £150 the other £100. Most makers in Asia will put your brand on the goods if sales are high enough in volume.

When I started my first teaching efforts in Texas back in the early- to mid-1990s Record was in transition of ownership having been partnered with the Swedish company Bahco. Bahco didn’t stay the course for very long and Rubbermaid muscled in for a season before Irwin Record took over to divide and conquer and then came the giant of giants Stanley Black and Decker who owns Irwin (and a zillion other companies). The rest is history but I say all of that because there in Texas in 1995 a rep came into the workshop selling old stock Record tools and equipment. He offered me a slew of Record old stock 52 1/2 Es for a premium price of $45. I still didn’t have enough for the school and that brought the Saga of import vises as working knowledge for me to write from. What’s changed? The reality of course is that I use my vises for ten hours a day every day and at least six days a week. I don’t imagine that there are many readers here doing the same. If there are, we are now the rare and dying breed. Still, buy a good vise and you won’t regret the purchase price. I personally think a vintage Record 52 1/2E is worth a few hundred pounds yet we can still get the secondhand ones for well under that price.

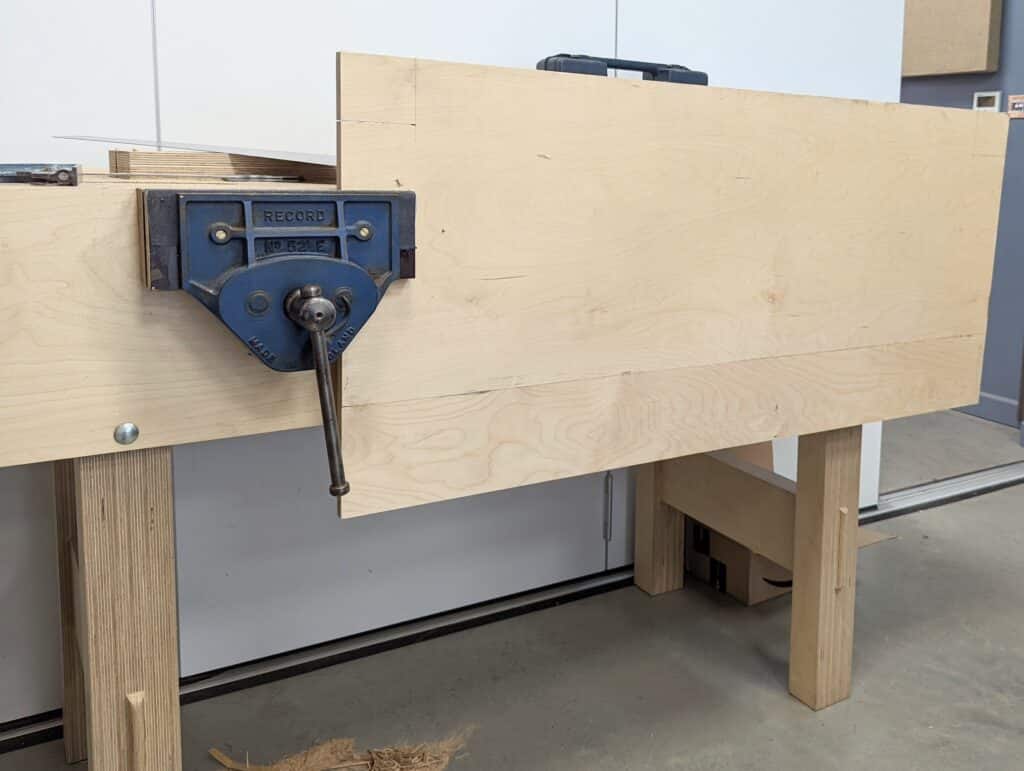

A good thing about living in the UK is eBay UK. Sellers on that platform are supplying vintage tools and equipment from an era of Sheffield making that is long gone and will never. Mostly this was the pre-import era when Sheffield goods lived up to a reputation earned through centuries of making and a domestic competitiveness that ensured reason in pricing. With those days now gone, eBay has become my best supplier for things like vises and of course suppliers of new tools and equipment also rely on selling via eBay as their so-called online shop. On one of my benches destined to return to my home garage, I had a Record vise but not my favourite QR. It’s a great vise but I am used to my quick-release versions and would struggle without one because I use my vise six days a week. John knew of a vintage Record 52 1/2E (not to be confused with its littler cousin the 7″ #52 QR — too small for serious woodworking but a solid vise and really good for children’s workbenches) for sale up the road here in town for just £50 so we went over and bought it. Now it’s installed in one of my workbench for my home garage. Now I can get to my point.

John will soon be holding small classes and has been preparing the workbenches to that end. Along the way, he has been making sure all of the benches and vises are in top condition after being stowed for the last four years. Our conversations back and forth included staring into stripped-down vises to make sure the quick-release mechanisms fully engage, which means he has to come to know the vises from the inside out, more than just pressing a lever and sliding the front jaw in and out. This is really the best way to understand the mechanics of anything fully and his finessing these elements has given him a much fuller understanding of bench vises with quick release mechanisms. The more you do it the more you own the knowledge and our conversations are mostly surrounding what an amazing vise these larger Record woodworker’s bench vises are. I also use a couple of Woden vises that are even bigger. Single-handedly, the vise jaw slides open from closed to over a foot, big enough for almost anything I care to handle in a vise for joinery and planing. I have chopped many many thousands of hand-chopped mortises in my vise through the decades and have never known a Record vise to fail me. If you are dogged about the front jaw vise having a vise dog you can make a channel in the wooden jaw liner and insert a piece of brass, steel or wood and that works as well as the metal ones if that is indeed what you want. Here’s a link to a how-to post of ten years ago that might help.

Conclusion: If anyone disses a vintage vise by Record it’s more likely that they are ignorant of what Record of old gave us. I suggest you can ignore them and buy a lifetime vise I doubt many others could parallel. In fact, any vintage vises made in Sheffield pre-Irwin days will be a good vise. Yes, things can go wrong, but these vises are really top-notch and with a little work restoration usually comprises minor surface rust removal from neglect. There will be many a thousand Record, Woden, Parkinson Perfect out there to be had that will give you a reliable version to install. Of all the vises I have bought secondhand I have yet to buy a bad one. The selling price will go up on eBay tomorrow for a little while but then it will steady down again. Never let anyone convince you that these vises aren’t the very best and most practical of any and all vises. Great width, great depth and unsurpassable length with the single press of a thumb. This article comes from my 57 years of using quick-release vises and one of those vises for most of those years. It is doubtful that anyone out there relies on and uses a vise more than I do in any given day. I reiterate that even now at not quite 73 years old I still work 10-hour days six days a week. My boast is because I’m a hand tool woodworker and not a machinist so every single piece of wood goes into the vise for planing sawing and chopping. I still have yet to find any alternative that is equal to the comfort and swift functional holding power it offers: no wonder the quick release was originally called a quick-grip. Far more appropriate than quick-release as it is less likely to release quickly than give its sure and steadfast grip. Nothing has ever really come close to the Record quick release vise in my view.

This above wording describing the patent validation is taken from original text but, of course, this cover is more of a pain than protection and the guard was totally unnecessary. Open access to the threads ensured regular lubrication and almost all secondhand vises come without the guard because the owners and users took them off. Vises require regular oiling. For me, using them so much, it’s about once a week. I think too that this is another example of an engineer designing and making something the user and the product never needed but came with the vise and became standard to it. Think thick plane irons, planes lying on their sides, Bed Rock planes and a zillion more.

This is the screw thread on my Woden No. 3, uncovered for so many decades.

Do you have any formed opinion on Jorgensen? I bought mine before they sold to a Chinese company but have yet to install it. Records I can find on eBay but for US with shipping it’s usually over $300 USD, usually 40-50% of that being shipping.

I am surprised shipping to be so high. That is not the actual cost so sellers often hike the price of shipping because it is a non-determinable amount and then too because they might be trying to deter shipping overseas. It’s the same in reverse hence I advise people to disconnect from overseas sellers and just buy domestic. Yes, Jorgensen have always made decent vises but not excelling in any way. Bit like their pipe clamps really but their pipe clamps have always surpassed anything made in China thus far. I never rated them as highly as I did the Record simply because they are not truly comparable.

Yeah buying overseas can be prohibitive. I assumed the $145 USD shipping was based on weight but still seems quite high. I did opt for Jorgensen’s larger 41012 4″x10″x12″ that seems discontinued now. Any recommendations for something higher quality I can get state side? Or is that mostly only the two brands/models you mentioned that are both probably overseas purchases?

I bought an Eclipse 10″ from Amazon for $160 shipped (with prime) when I built my bench. Can’t post links but search the Amazon product code B004OCH206.

It appears to be the same vise Paul installed in the newer workbench build, except he used a 9″ which is also available on the same product page. I figured for $15 more I’d go ahead and get the 10″. It’s still the same price and available now, but I recall there were periods of unavailability and waiting for stock to return back when I got it.

I’ve been quite happy with it and very much appreciated Paul’s suggestion to get this particular vise.

I picked up a Pony Woodworker’s vise in October of 2020 to bring my woodworking hobby up a notch. By July of this year it had finally broken. I think the cast iron wasn’t hardened properly, so the lead screw slowly nibbled away at it until it be came quick release plates (I could push it closed and pull it open, but it could no longer hold a piece of wood — It was no longer a vise). After some bothering of the company they did send me a replacement (it has a “limited lifetime warranty”), though I am not sure if I will mount it to my bench or not (I was able to obtain a Record QR 52 1/2 while I waited for the replacement).

Short story long: I won’t be recommending that vise to anyone unless they truly can’t afford a used 52 1/2 and I’m not sure the Jorgenson heavy duty woodworkers vise will fare much better than the pony one.

So I bought a record vise around 15 years ago, it was on the clearance table at my local woodworking store. I paid at least $140 for it and at the time it wasn’t cheap. Well I couldn’t loosen it up, the tolerances on the guide rods were too close and no matter what I tried to do I never could get it to pull out easily when the quick release was activated. Then one day I tightened it too much trying to stop a board from slipping and I distorted the main screw.

It became only good for an anchor after that and I tossed it in the scrap heap. After that I bought another vise from a school that surplused all their woodworking equipment. This one didn’t have a quick release but had an acme thread. It had seen some abuse but it still works like a charm. It’s very expensive to manufacture an acme thread, I wouldn’t buy one unless it had one.

Since then I bought one that works on a hydraulic principle, ( no screws) this will be for my new bench when I build it. Time will tell if this new design will hold up I guess.

So it is not the vintage models I have reflected on but from the Irwin or Bahco era I exposed.

Hi Paul,

I bought the eclipse QR vise (the 7’’ version) when i made my bench about 3 years ago. In the past year, i noticed i cannot open the vise without the use of the QR. When turning the handle counterclockwise to open the jaws, it feel a click every rotation. As if it « jumps » over the mechanism that is supposed to push the jaw out. I looked into it and it seems that my outside jaw is lower than before. There is some rattle with the front jaws. I can move it upwards a half cm or so. If i were to hold it up and try to open the jaws with the handle, it works. But on its own (when the jaw is lower), it wont open. I have to use the QR to open the jaws.

Have you seen this before?

Thanks,

Paul

The ACME thread is not the best one for such use.

You will notice on the pictures here that what is used is a “buttress thread”.

It is a thread which maximise its strength in one direction as the effort is in tightening the vise and not in opening it.

search “wiki buttress”:

“(wiki) The resulting thread form has the same low friction properties as a square thread form but at about twice the shear strength due to the long thread base.”

Although the York vises (York.CZ) have a trapezoidal thread, Paul has had problems with them in his US school. We don’t know if any action has been taken to correct those problems. So there is more to it than the screw thread.

Mass or weight? To which of Newton’s three laws of motion should we consider?

Decisions, decisions, hmm!

As long as we do not plan on using our benches on the moon and over, I guess we can settle with both 🙂

I bought a 10” QR vise from fine tools .com in Germany 12 years ago made in Czech Republic . Can’t fault it €119 then

Hi Paul

Could you show us on one of your videos or q&a how to fix a vice that keeps slipping, the only way for it to hold tight is to put a wedge between the QR and the threaded handle bar

Could Mr. Sellers determine the weak or problem areas of the Eclipse vise so that perhaps those of us who have access to metal working tools could modify those issues. Those of us in the US may never have a chance to study a Record vise to know the differences in construction. My Eclipse is starting to rack from 5 years of fairly heavy use and I have been thinking about what to do. Timely article : ) As always , Thank you.

On my woodwork bench my main vice is one of the indian copies lion brand.

I bought it secondhand for not very much, decades ago. It works well.

My engineering vice is a 6″ record 112. Built like a tank. I do also use it for woodwork, having made wood jaws for it. the extra height is sometimes useful.

It was seized when I got it, for free, but soon freed off. The last time I looked these cost £750 new. So the hour that it took me to free it off was a good use of my time.

Often I have “attacked” what I have held in its jaws with a sledge hammer.

I just wish I could find someone that knew how to safely ship them. After buying 3 that arrived broken I gave up and bought an old Wilton locally. At least I have lots of spare parts for record 52 1/2 in case I ever need them ha

Paul – curious if you have an opinion on the Morgan 200A? They are still made in the USA and vintage one’s are available on ebay.

I have an old Morgan 200a installed on my bench. It is a good vise but the quarter turn release and no continuous take up is frustrating at times. All parts are still available from Milwaukee tools and Equipment. When I bought vise it was frozen up so I asked guy if he had any other woodworking tools and he showed me an old M-f number 9 plane minus nob and had him throw it in too. Got a nob for eight dollars on e-bay and it is a wonderful plane. Not bad for forty dollars total. If an old 52 1/2 e ever appears though that Morgan will be gone.

I have been using a Morgan QR vise for years (purchased new from Tools For Working Wood) and I couldn’t be happier; it’s heavy and smooth functioning, and bonus, it’s made in USA with replacement parts available (as noted above). The finish is a little rough but easily smoothed out with a file if desired – I didn’t, it’s a steel vise with wooden jaws, it holds wood, moves easily and never failed to hold release of hold. Jim

Paul,

When I was in shop class in the late ’50s in Los Angeles, all of the wood shop vises were Wilton. When the LA schools discontinued shop classes, I was able to buy two of the 10″ Wiltons for $10 each. They are not quick release, but the one I kept when I moved is still solid and working fine.

Did you ever encounter Wilton vises when you were in the US?

Mine is quick release, but there’s no lever, if you spin the bar twice quickly it releases to open with a pull and re-engages as your turn the bar clockwise again

Keith, I didn’t realize Wilton made quick release vises. I also have one of their metal working vises that I bought from the same guy who had the wood vise. All through school I only saw their vises in shop classes. I bet they were the simplist, most durable vises they made. The kids in my shop classes were pretty rough on everything. Do you have a model number for your Wilton vise?

I am building a bench out of 8/4 western maple and have the wood. I will start on it when the weather cools a bit as it has been in the 30s lately. I have a Veritas 9in for the front and bought an Eclipse 7in QR with a dog in it for the rear of the bench for hold down. I have it attached to my current takedown B and D bench on a slab of 1-1/2in particle board until I have the bench assembled for its final home. I sold Record and Marples for 30yrs but was very disappointed when Record got bought out and there would no longer be parts availability. I think that Veritas will be my choice in the future as their customer service is impeccable and quality is way up there. So far the Eclipse has been working very well so for less than $100 delivered I am happy.

Correction, it will go on the right end of the bench, not the back.

“Here’s a link to a how-to post of ten years ago …” Well no, there is no link. Could you correct this please?

search for the video “Retro fitting a Non-Dogged Vise | Paul Sellers”

also shown in post “HOW TO BUILD A WORKBENCH – VISE PADS AND DOGS (PART15)” dated 23 June 2012.

Sorry no links admitted in comments.

“no wonder the quick release was originally called a quick-grip”

I have always find “quick release” a misnomer.

Even on a non-quick release vise a half turn or a turn of the handle will quickly release the piece.

But only a quick-release vise will allow one to change significantly the distance between the jaws without having do do a lot of handle turns.

I would have called this a quick-setting vise.

IMO a quick holding system is an important safety item as one will not hesitate to clamp the piece with it instead of using one’s hand.

Sawing the piece in the vise is safer than using a bench-hook.

As I have read on a forum: “Your hand is not a clamp”.

Paul, I bought a Record made in England QR 52 in 1988. Brand new. From day 1 the quick release would slip back a couple of screw threads when tightened to the work. I have taken it apart and filed a very small amount where the quick release met the main screw with no affect. 90% of the time when tightened against the work it slips back, and I have to tighten it the last couple of turns by hand to bring it tight against the work. I am at my wits end trying to make this vice work properly. I have put up with it for over 30 years now but it still makes me angry that it doesn’t work properly. Is there a cure for this? It seems that the rot set in to Record way before you said it did.

Have you tried tightening up the quick release spring?

Hi, thanks for trying to help. Much appreciated.

I haven’t tried tightening up the spring. The QR lever actually takes a good hard force to push in, leading me to believe that the spring is wound up fairly tight as it is. The cogs on the quick release don’t seem to want to mate with the screw when the QR lever is released, leaving it to jump back when the handle is turned for the final tightening. The strange part is that maybe 10% of the time it will work perfectly.

I prefer the softer spring to the QR. Often they are way too tight even for someone like me with a strong and firm grip. A single turn back makes life so much easier.

Paul, I recently got a Record 52 1/2E in really good shape. Only some rust on some areas of the face and the QR lever where the paint flecked off but none on the screw or any internals as far as I can see. It came really greased up with some really viscous stuff, so I wiped it down and sprayed it with degreaser down to dry metal, then lightly lubricated it with CRC 3-36, rated the best lubricant and rust preventative by Fine Woodworking. The action is very nice, though I have yet to build my bench to really try it out. It has the screw&nut cover (no rust on it at all). Should I remove this cover or should I leave it on?

As several correspondents have mentioned, I too bought an Eclipse QR9 a couple of years ago thinking it would be better than the cheaper Groz I had on which the jaws didn’t align and were not parallel. Despite adjusting the wooden jaws I installed on the Groz, it continually went out of alignment. Unfortunately the Eclipse suffers not only the same problems, but now slips on the QR mechanism so as you tighten it sometimes it releases, skipping a thread, which is disconcerting at best and downright dangerous at worst.

Evolution ain’t supposed to go this way. I wonder if it’s changed to the survival of the cheapest or survival of the consumerist always demanding low prices until all competition is gone and then selling whatever the remaining company can get away with. Course, if a company in the US or Europe says make it for this price and we’ll buy ten thousand from you and they cut costs to supply it or everyone abandons the good companies for the knockoff imports just who should get the blame? I’ll stick to buying secondhand. They keep cycling through and there’s a good supply on eBay every week. Groz should be gross maybe.

My Eclipse has done the same since day one (3 years ago). It will usually slip once after bringing in the QR. It doesn’t bother me much as I know to expect it. Sadly, ebay AU is not nearly as good and it was pretty much the closest to a Record that I could find.

I have the same problem with my vise, after pushing it for tightening, most of the time, I have to make a half turn anti-clockwise to engage the nut before I can tighten the vise.

I have found yesterday on wiki Split nut:

“The two halves of the nut have chamfered ends (60° to axis), which helps the threads to find engagement during the closing action.”

Now I have to unmount my vise to see if the manufacturer has simply omitted this machining operation to save a little money.

The two half nuts on my Record still had casting remnants on the ends. I filed them down but it didn’t make any difference to the operation of the vice (still slipped). As much as I like my older record tools, I think that by the late 80’s quality control was non existent.

Sad to say, I’m afraid the demise is permanent, terminal for many UK makers. How the giants fell when they sold out to bigger giants. I mean, imagine the plastics empire Rubbermaid owning a tool-making company like Record as it did at one time!!!

Hi Sylvain,

I have the same exact problem with my Eclipse vice (9″).

By any chance, have you already checked ?

I find it a bit dangerous even though I am aware of this behavior.

Hi Paul

Would you do a blog or vlog on vise servicing and maintenance; I don’t think you’ve done one of these yet?

I have a large Woden vise, ex school I think, which is pretty pristine – cost me £100 two years ago. When fitting the vise it rotated in my hands once by accident and the thread cut me to the bone just from the pressure generated by the weight of the vise – the precision of the engineering is really something! But I’d like to keep it working well for the long term. A tutorial on looking after these things, servicing the QR and general maintenance would be really useful I think. In the main people seem to assume that these are simple and solid so no guidance on maintenance is necessary; but that’s not the case on something that can last 100 years plus.

This may seem like a silly question, is it harmful to a vice to have it clamped over a couple of days? Like when using the clamp in the vice and leaving it there.

I have a 52 1/2, best tool I ever bought. Absolutely rock solid.

What is the a difference between the Record 52 1/2 and the 52 1/2E? I’ve never seen either in person and I can’t tell the difference based on photos online.

Found the answer in the blog after re-reading.

I was lucky enough to be given a Record 52 1/2 E a few years ago. It’s a good vise, though does have a small problem. After using the quick release the screw mechanism doesn’t always engage properly. A bit of jiggling usually sorts it out so I’m not bothered. Perhaps I’ll take a look at it in the winter. Might need to get a hoist first!

What about vices/vises made of wood? The old timers liked them, worked them and it was good enough to make masterpieces? Are there any good words for the old school leg vises etc.? Or are they junk?

At least a woodwork could could build their own on the cheap and have a Poorman’s Vice.

What is your recommendation regarding main bolt protection?

How to prevent saw dust to drop on it?

Do you recommend oil or grease? (for lubrication and rust prevention)

Best regards!

I’ve relied on 3-in-1 oil all my life. No, fuss no mess, no grease, no rust. I certainly see absolutely no point in sawdust protection because it never clogs or gets messy from such dust.

I’m just glad I’d found my Woden a few years before the price got “Paul Sellers-ed”

The cost from Wales to Australia was ok at the time with a then decent currency exchange, and a nice vendor able to make use of Royal Post shipping at the time, not so much now via eBay and their internal shipping scheme.

But they are properly made by people who knew how to make them properly !!

And … as Paul may have mentioned before, we are really just the current custodians of well looked after tools for future generations, if we look after them well.

Go forth and restore some tools 😉

I lucked into an 8″ vise from Abernathy of Chicago a few years back. Paid $35. Research shows it was built between 1906 and sometime in the 1930s. It has only six pieces. Two faces, two guides, one screw, and a free floating thread piece. Flip the handle counter-clockwise and the tread piece disengages and you can move the face back and forth. Flip it clockwise, and everything engages again. It’s mounted on Paul’s bench and works perfectly.

I got it off Craigs list, where I have also found a #4, #5, #7, 28″ Diston saw, and a Fillister. All the planes dated before 1920. The most I paid was $50 for the #7. Lowest $25 for the #4. Everything was within 25 miles.

Very interesting analysis thank you Paul. my Record 52 1/2 from the 1960’s lives up to your evaluation, but my two favourites from the pre WW11 period are my pair of “Parkinson’s patent perfect vice” handed down to me by a wonderful retired tradesman. Clearly at least 90 years old, the front cheek cast integrally with the runners, they are still working perfectly. It is my understanding that Parkinsons handed over manufacture of smaller components like vices to Hampsons, and thus they became Record, as part of consolidation of areas of manufacture before and during the war. Parkinsons were apparently required toconcentrate on huge machinery for the war effort. I have seen early Record vices with the same rounded Knob style as the Parkinson, the parentage is clear. it would be great to find out more of this history. Here in Australia we have had two manufacturers giving us similar styles and similar quality to Record – Dawn and Joplin. I can’t comment on the quality of older versus recent, but Dawn are certainly still available in some styles, particularly machinists vices.

Hi Paul, I wonder if you have any opinion or information on the record no. 52 A?

I have found a really old one for a reasonable price but I cannot seem to actually find any info on that particular model no.

It looks like my previous reply may have been moderated for sharing a link to another site?

The no. 52 is the 7″ wide jaw version (52 1/2 is 9″, 53 is 10.5″).

The “A” denotes that it was the more expensive model with the patented dust cover over the screw (the thing Paul talks about removing).

As I was looking thru Record vises in E-Bay I notice that Irwin has record vises did Irwin buy Record out and are Irwin records vises any good?

In E-Bay I saw Irwin record vises did Irwin buy Record out? How good are Irwin record vises?

They did and not too great. Certainly not Record of old, maybe 25% as good.

I was keeping my eye out for a vintage Record 53, but I came across a Parkinson Perfect 16 locally first, and I couldn’t be happier with it. At some point it was in Newfoundland, and came across here to Cape Breton. A bit of a clean up, and it works beautifully. I think it’s a bargain at $50 CDN and a short drive to pick it up. Those old vises are worth hunting for.

Dear Paul,

When I made your workbench, a few years ago, I purchased a vintage Record 53 vise that must be a 100 years old by now. It cleaned up perfectly and work like a charm. My only complaint is that the jaws are unparalleled. I doesn’t matter most of the time but I wonder if I could correct the issues?

I thought about simply making the wooden jaws at an angle but I worry it may make it worse in the long term – for the next owner or the one after!

I think I remember to have read that these jaws are not meant to be parallel when open (vertically). They grip first on the top and then should become parallel when they grip strongly.

It depends on which way they are out of parallel. Top to bottom, narrower at the top, is a design feature intended to start the grip and adjust as the jaws are tightened. Out side to side is rare but it can be an issue as this is often caused by someone forcing the jaws onto a piece at one end and overtightening enough to rack the mechanism of the vise.

Paul I pity you with this Blog. I am afraid that you will be forevermore diagnosing vise problems. But I am searching ebay as I type this, thanks!

Throughout my life I have been in and around workshops, especially as a boy. There are a plethora of tool manufacturers names in the UK that have passed. Some are still known because they were bought, some do not survive except in the ‘vintage’ listings on eBay.

When I left school I trained as a fitter and so at college and work we used the vice which almost always had the Record name cast for eternity. Many, many apprentices had learned their hand skills on these simple but well made devices, I bet it was just the same in the joiners workshops across the way.

I was so under this impression it never occurred to me that Record everade other tools other than vice’s.

Every apprentice buys their tools and often lists of essential tools are made. But for the record, I bet there was not a day in 5 years of my training that a Record vice was not used (and possibly abused a little). They are the essential tool. Woodwork, metal work whatever. They just keep going. I know of four 52 1/2 that were bought for around £20 each. They work every day. They were made in the 1930’s. Pretty sound investment.

I :

– Was about to spend months of savings for a crisscross leg vice Made in USA.

– Read this post.

– Went on eBay.uk.

– Found a Paramo 51.

– Ordered it.

– Received it.

– Became the happiest Paul’s french follower.

– Finally seriously thinking about considering UK imperial measurement system as a forgivable thing.

Thanks and best regards from France!

Great to see a picture of the Paramo 51 – this is my vice, bought new here in Sheffield around 1982, when we got our first house and I set up my workshop in the cellar. The bench was made out of old floor joists and wall plates (for the legs) from demolished houses – still as solid as a rock 40 years later, and now in our second house.

I bought my first set of tools – all Sheffield made – in 1976 through a friend who worked at Stanley, though from what Paul says, by then the quality was going down. I recently acquired an old Record no4 plane and it feels so much better then the Stanley no4 from back then. Also my Garlick Lynx tenon saw – bought when the firm was still independent – is so much better than the Stanley one it replaced.

Sad though to hear yet again of the demise of good Sheffield craftsmanship, which I am acutely aware through living here – just today I heard of a small firm setting up some sort of machine controlled grinder because there was no one left who could hand grind.

Thank you Paul that was an interesting article, prior to reading this article I just purchased a 10’ inch Rededa vice, the information I could get off the web is it was made Sheffield and was for sale in a catalogue in the late 60’s.

How old it is I don’t really know, but it is my first vice going on to my first bench so we all have to start somewhere .

I just found a Woden model 89 No. 2 in good shape for a reasonable price. I’ve seen the 189B No 2, but I’m unfamiliar with the 89 and I can’t find any info on it. Do you know anything about this model?

I am afraid not, Nicholas. I only know the ones I have or have used.