Keeping It Real!

It’s hard to say when I started to see certain differences in my world of woodworking from that of others. I think mostly it began in the USA. before I migrated I only knew of what I saw in woodworking magazines, in my own rather isolated world of making where there seemed to be a period of flux when hand tools were diminishing and the almighty so-called power-tool woodworking was rushing ahead completely unchallenged and seemingly unstoppable. At that time, when I arrived stateside in the mid to late 1980s, I never met a single woodworker who was working with hand tools beyond a hammer and a 25-foot tape. Go into a woodworking store like the Woodcraft chain, or Rockler and most of the shop floor was dedicated to machines and a mass of related equipment ranging from infeed and outfeed collapsable tables, extraction equipment, books and plans and a massive section on lathes and turning equipment and so on. It made me think about where woodworking was heading. Visit any home shop in the garage and most of them were the same too. A $3,000 One-way lathe now starts at double that, a Sawstop tablesaw at left in the picture goes for around $3,000 on up, bandsaw, chopsaw, radial-arm saw, planer, actually two, a jointer and a thicknesser before combination machine became popular and then all of the other stuff it takes to support the work, etc. In my shop of a few square metres, no more than ten, max, I had a workbench and my hand tools. Now I did start an aspect of my business work-life where the whole of it went the same way in that I had a couple of lines that developed machine-made products. I enjoyed that side of things too; the challenge of coming up with something saleable that produced higher levels of income. But I always kept my hand tool shops free from the machine area, always separate wherever possible.

Today I have enjoyed seeing the change come full circle. I know that the majority don’t want hand work and do want machine work. But the joy for me is seeing more hand tool woodworkers than I ever thought possible when I began my outreach almost 40 years ago when so few saw hand tool woodworking as a viable option.

How real is my workshop? It’s as real as any I have ever had. In the USA I had nine workshops over 23 years. The best ones were always the commuter-free versions next to my different homes, I moved five times; one of them was less than a quarter of a mile away across a field, along the edge of a woodland and through a large vegetable garden. It was here that I discovered a deep affection for the North American bluebirds, cavity nesters that filled a deep need in my nature-watching life for more than two decades once I discovered them.

I always enjoyed being with my family every day and for several different reasons. Food is a wonderful unifier and eating meals together is the best vehicle for catching up with everyone and everything. They all loved coming into the workshop with me to make whatever it was they were working on; the list is too variable and extensive but I taught all of the four boys to make and make they did. To give all that they made here is too much but they ranged from my 14-year-old making his whole bedroom pieces for his room to a Nasa space rocket turned on the lathe, chicken coops, gifts in the form of many boxes, wooden spoons and spatulas by the dozen and then wooden mallets and workbenches they sold for income. Should I mention Josephs’s Cellos and violins, a first guitar and many a dozen other things not normal for a family at home? Mostly it had a lot to do with living in a new and strange land a million miles from anywhere after living in the major city metroplex of Greater Manchester. Reagan Wells was 32 miles from Uvalde, Texas, 16 miles into a dead canyon crossing 5 low-river crossings; it was there that I built my first house on a half acre of land surrounded by some very wild land owned mostly by the former Governor of `texas, Dolph Briscoe; he owned a million acres. Imagine.

Attaching your workshop to your home is financially more manageable than renting a second place to work from and, of course, commuting is nonexistent. Life was much much easier in the USA. In the 1980s, no one bothered too much if you had a shop on the side of your house. Living 32 miles out from the small town of Uvalde with its then population of just 6,500 and then along a county road with 20 houses along a 16-mile stretch meant your neighbours weren’t too close up against you. My neighbours at the time were woodworkers too, so we both made the same noises on any given day.

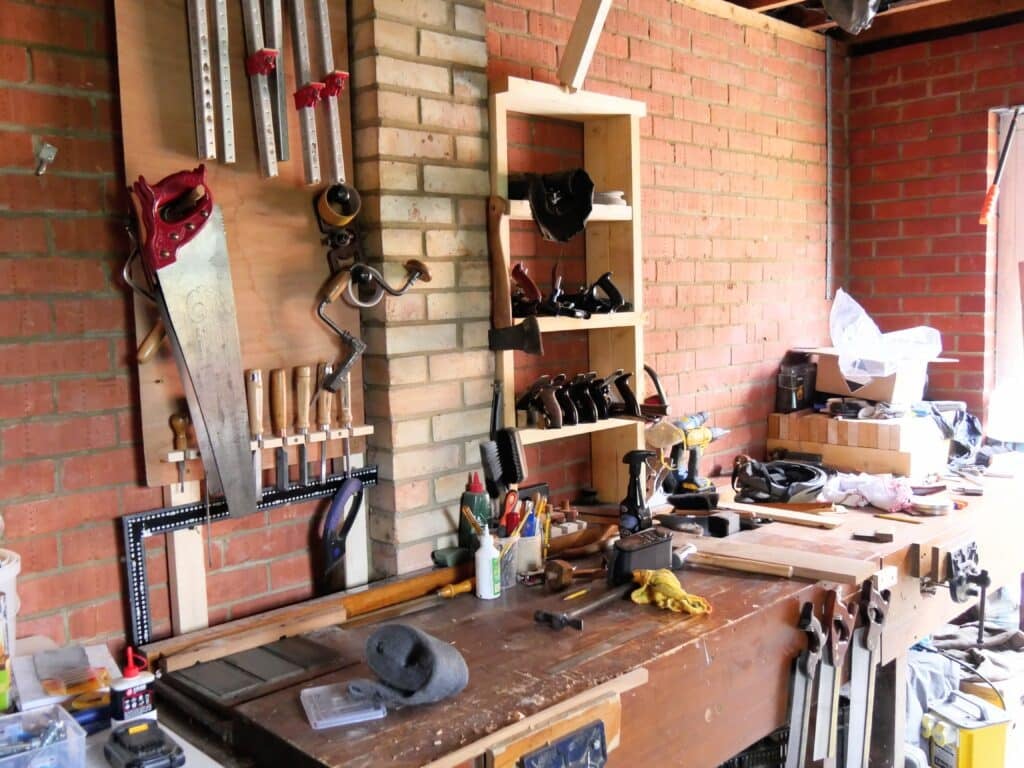

Many things changed through the years. Since then I have worked my way through about 16 workshops and always had one up against the house even if my daytime workshop was off somewhere else. Times and situations change for many a good and bad reason. Finding permanence for me was in the work and not the location or the shop and one thing I discovered is that the shop size, place and type may well change but when you have established your patterns of work you arrange the bench, the tools, work support, etc according to the patterns you have established to work to. Workshops are an evolving process. For many full-time professional woodworkers, a big workshop is the dream that parallels masses of quite sophisticated machinery, dust extraction, support equipment and lofty air space. My walk seems to have been an exact opposite, a deconstruction that’s a reverse evolution if you will. Where I am now, what I have, is a space of just a few square metres. I recall selling one of my UK homes back in the 1970s when the estate agent said he loved my simple kitchen design. “It’s small!” he said, “But you have the perfect golden triangle! Fridge, sink, cooker!” `mine was a very efficient kitchen and one most people cooking would look for without even knowing why. The efficiency of a kitchen enabling the cook to get meals to the table in a timely order revolves around these three key points. So it is for my garage, workbench, hand tools, and bandsaw; nothing is more than a metre away from me. If and when there are more makers in a workshop and when you are on a narrower time margin and need machines you can quadruple this size. In our case, you, me, we make a piece, gift it, use it ourselves or sell it. We’re not going to make more than one or two and it can all be made within the confines of four or five square metres including the footprint of the bench and bandsaw. It keeps it very simple but it must be orderly and clean to really work. Not too much on the floor and zero clutter.

We put out a video of a tour of my workshop on YT recently. It was really popular and I was surprised how many liked the realness of it and its reliability to them and their circumstances. I put this down to my personal security and sense of identity as a true maker. I don’t and didn’t need to invent myself, reinvent myself, present an unreal me or act out a performance of superspeed woodworking that wasn’t me at all. No red suspenders and neckerchiefs as sweatbands, no cargo pants nor the pretend ripped jeans of a working man. What you see or saw is what you get or got. I didn’t need a title of minimalist this and hybrid that, nor British this or that either. You know, the things that mostly serve to separate rather than unite. Woodworking defies race and male/female specificity, tears down the barriers between professional and amateur. I occupy my space contentedly without retention and having to prove anything to anyone.

Having my workshop at the studio evolve means it has emerged as a real space to make in for me. You might recall I had a drill press standing there for about four years or so. Well, truthfully I used it about once a month, mainly for drilling metal, not wood. It didn’t take a big footprint but somehow it superimposed itself on my comfort zone in the workshop so I finally ousted it to another area where I do metalworking, not woodworking. It gave me space for a very nice sharpening bench that I have set up for when I sharpen a large batch of tools at one go and for when my vise is occupied with woodwork. What better use of my space!

With the garage reworked so that there is no hint of damp rising from the concrete floor or coming through the walls, I am now replicating in reverse what I had before. For complete success, comfort and to avoid confusion it must pretty much replicate the workspace at the studio. Tools identically placed, identical workbench, shelving etc. It will be different in that the half that is normally occupied by cameras and the film team is another unique work area where I can write and study and even relax and listen to music. The difference in footprint is different but only minimally in size. The depth I gain one way I lost the other, but the added depth the other way allows room for a small desk table and a compact recliner. Please, no reference to ‘man caves. That serves only to patheticise men and quality adult malehood and will likely take you into the realm of big-boy toys too. Thankfully, that usually refers to machines, so I am ‘outa here!’

My next garage workshop was when I finally arrived to live in my native England and was based in a rented house in Abingdon. Being able to walk around your bench to work on bigger frames like headboards and tabletops obviously is an advantage but in a small space it becomes a luxury and actually we generally do not need it more than say once a year. Even so, the advantage of having the bench against a facing wall is the space behind you opens up for sawing planks and sheet goods on saw horses and then too assembling larger pieces like beds and dining tables. At the studio garage where we mostly film I have the bench on wheels that elevate via cam-action levers. As it is with many things, the makers dumbed it down in metal thickness to lower costs and ease manufacturing them. For a heavy bench like my plywood version they only just work but not well enough to install them. I just lift and lug one end at a time to move it. So too at my new home garage version. I recently reconstructed what I did three years ago as a temporary fix in my house garage. The shelves above the workbench were for genuine work but I used some recovered plywood and my upcycled softwood bench there. Within a few weeks, I discovered a really deep damp problem. Every surface released water at not quite running but near to. The garage needed gutting! Tearing out the slab and replacing it with membrane and insulation, drylining the walls, roof insulation and installing good drainage to take water away all served to give me the control I wanted. I needed to keep my tools and wood in a good environment.

Mr. Sellers, I used to build furniture with machines but I started working wood and building furniture with hand tools only (e.g., various desks, tables, chairs, stools, beds) about five years ago. I took the hand-tool only route in my little basement workshop mostly due to the inspiration that I received from you, John Brown, and Tom Fidgen, a Canadian woodworker. I cannot express the pure joy and delight of building a large project comprised of mortise, tenon, dovetails, and breadboard ends with just hand tools in a quiet and (relatively) dustless environment. Do these projects take longer than working with machines? Sure they do (but not by much!). Hand-tool built furniture has a special verve, energy, and spirit that cannot be matched by machines. I truly hope more woodworkers do not get trapped by the belief that they need every new machine and tool out there to be a woodworker. Before anyone buys a machine they should first consult your videos and writing.

“No red suspenders”.

I have adopted suspenders about 6 years ago (not red though). It is so much more comfortable then a belt (when one has a small belly). I didn’t adopt it for the look but instead despite the old grandpa look it has where I live. Sometimes it doesn’t fit with some clothes. What an inconvenience it is to have to reverse to a belt.

Back to the subject: my workspace is about 2 X 3 m in the attic. There is the former son’s room (now a guest room) which I can use for assembly if need be.

Hi , I like braces as we call them in the uk, would not be with out them

I find it amusing that, for a hand tool user, I’m willing to bet you can tell whether the person is left or right handed by simply looking at the orientation of the tenon saw hanging somewhere within arms reach of the vise.

Thanks Paul for sharing the home shops. I thought they were likely simlar to the one you film in; still nice to see them. For the wall unit you created to house much of the tools, did you use housing dados? It looks reasonably straightforward. I have thought it would be nice if you could either film a short video about its specifics or briefly write about it.

I did use stopped housing dadoes throughout Joe. And it was straightforward using ready planed 22mm material also known as one by eight or eight by one depending on which side of the big pond you live on. That’s 200mm by 22mm for the rest of the world.

Dear Paul, enjoyed this treatise as always. Thought I would ask you a question if I may.

I have seen your videos where you have used the Stanley # 78. Recently acquired one in very decent shape so I am tuning it up. A little intimidated about sharpening the spurs / knickers.

Have you ever given a thought to producing a video to show your preferred method of sharpening such to your audience? Be much appreciated to gain such knowledge.

That’s a good nudge because there are several idiosyncracies to this plane. I go through it quite thoroughly in my book Essential Woodworking Hand Tools and it really is a very good tool to own and use.

Hi Paul, How did you hollow out the log in the nesting box photo above?

The wrens skipped our traditional box this year so I would like to try a new design.

Jon

If you spend much time in the wood, you will find that many a log has been hollowed out courtesy of the local insect population.

Where I live in the Southern US, we have gum trees that are often hollow. People used to use sections of them for storing grain and other things. There was one in a barn in Cades Cove that was big enough for me to easily stand inside.

I have a section of one that is just the right size to make several birdhouses like the one pictured.

I too have wondered how to hollow logs for nesting boxes for years ! Is it even possible by hand? Perhaps one has to saw the log in half, use a gouge to hollow out the two halves and then glue it back together? The only other thing I can think of is to chisel out the waste like a huge mortise hole, but that would take quite a while and presumably would result in a square inside a circle as it were.

Hi Paul,

Yet again another inspiring blog. So refreshing to see someone not just “keeping it real”, but living it real. I would love to know what you used to get those doors such a great transparent red colour. Thanks again for your tremendous contribution to woodworking.

‘Man Cave’… more like a man’s grave!

I’m not anti-machine, but wow it would sure take a lot of room for: a table saw, a jointer, a router table, a planer, a bandsaw, a drill press, a drum sander, a bench grinder, another slow speed grinder for sharpening, and machinery and conduits for dust control and etc. And wow, wouldn’t it always be noisy and wouldn’t I corrupt my hobby time by having to constantly suit up with masks, goggles, ear plugs while always having to super focused or risk losing a finger. And finally, wow, I could spend all my time engineering and building complex jigs and contraptions for a one-time task. I think machines are great for industry and I’m glad we have them. I do love my bandsaw and wood lathe. I’ll likely add a drill press one day. My bench grinder justifies the space it takes up. I don’t miss the rest. I’m sure I could find a use for machines given unlimited space and dollars.