Some Things Look the Same

In this thing called ‘progress‘, we often consider the lower price to be our gain. That would be called progress in many camps, maybe most. In the reality of life, what’s now called the shrink-economy would have at one time been called simply a con. Why we don’t name it for what it is I don’t altogether know but I can give a good stab at it if needed. As we now know, it is to keep the outer looking just the same but make the contents inside somewhat less. Candy bars and cereal packages are a good example and key players in this. They did this so as not to lose sales by upping the price. Mostly it’s about perception and perspective. It’s only when you look inside that you see the shrunken candy bar wrapper and half empty packet that we get to see the differrence before and after.

In times past, I am talking three decades ago now, a good bench vise was somewhat hard to get hold of. At that time the English-made Record vise made by the then Record Tool Company in Sheffield discontinued the line of quality woodworkers vises. A decade later we saw some Asian vises replace them but not quite. There were good and bad versions but none matched the Record versions. That’s changed. I have seen some good quality vises come in from Asia and even trialled one or two of them.

The clamps I now use and prefer to all others are something of a good example of reverse progress relying, like any good lie, on standing in truths stead. From the outside these clamps on the outside all look similarly made. The makers kept the outer the same but shrank the insides by reducing the thickness of the walls. This was done in the interests of competetion, I understand that. There is no doubt that the original aluminium sash clamp with its extruded U or box profile was a substantial clamp––more than adequate for just about all of any woodworkers clamping needs. The Harbour Freight version and then many others too had similar-looking alternatives made but by shrinking the thicknesses of the walls by at least two-thirds and more: not all clamps are created equal or anywhere near. So too the threaded adjusters. The original Acme thread was substantively made with deep, square threads that were well made and accurately matched. Those that followed did not set the same standards and after a short while wear caused the clamps to jam and to bend under very little pressure. The three clamps to the right of the six below are substantially made while the two on left of centre are much thinner and the far left one resembles the tinfoil used in baking.

Place the clamp bars alongside one another and you see the contrast but they do all work. It’s good that clamps of recent make can show improvement in wall thickness. The clamp on the right is the most recent version offered for sale here in the UK. It is the most substantial model sold here and comes from Rutlands. But I don’t think anyone should simply dismiss the mid-weight lighter weight versions for heavier ones. These do work as I said and especially for the shorter lengths around 24––36″. I have used these mid range quality ones since 2007 and 2010. That said, I am surprised the prices of these have risen so markedly and the Rutland do give the very best value for money by comparison. I find this especially so because the clamp is so very well made. I bought four of their 600 (24″) length clamps as a package deal for £80 delivered and they are twice and three times the quality and standard of say Hilka. The equivalent from Juuma in Germany, which is a close comparison to Rutland, is around £29 but then you will have taxes and shipping to pay outside the EU.

The Universal Clamp Corp version above is out of most woodworker’s price range I think being as you need so many. $68 per clamp, so £55.

The UK Faithful and Silverline are very much cheapo versions and this is definately needs some thought as the difference in cost between Rutland and these makes it a no-brainer to go Rutland even if you must buy in packages of four.

This is the Juuma. After years of using them, and this is the best way to really assess anything, I find the mechanism a little clunky. That should not put you off though. You might like them and they are very substantial clamps.

You can see that Rutland made an increase to the clamp heads in both width and height. This was not necessarily a plus for me as they can be so big they can get in the way on some tasks. I will give it a year to see. I will say that this area of the clamp is very nicely made and finished with all metal components that look and act the part of a quality mechanism.

All of the clamp bars measured close to one another on the outside sizing at close to 7/8″ (21mm) by 1 3/8″(33-34mm). You’d think that all makers and suppliers were all singing from the same hymm sheet and I did wonder why this was the case. Of course, the walls of the clamps are where the sizing was reduced in some poorer grade and poorly made clamps.

All of my clamps have wooden inserts to improve the feel and reduce the torque on the thinner-walled versions. This makes an amazing difference to the clamps and I added wood to one of the Rutland ones and it takes out the rattle caused by metal on metal but for strength and functionality it does not need it.

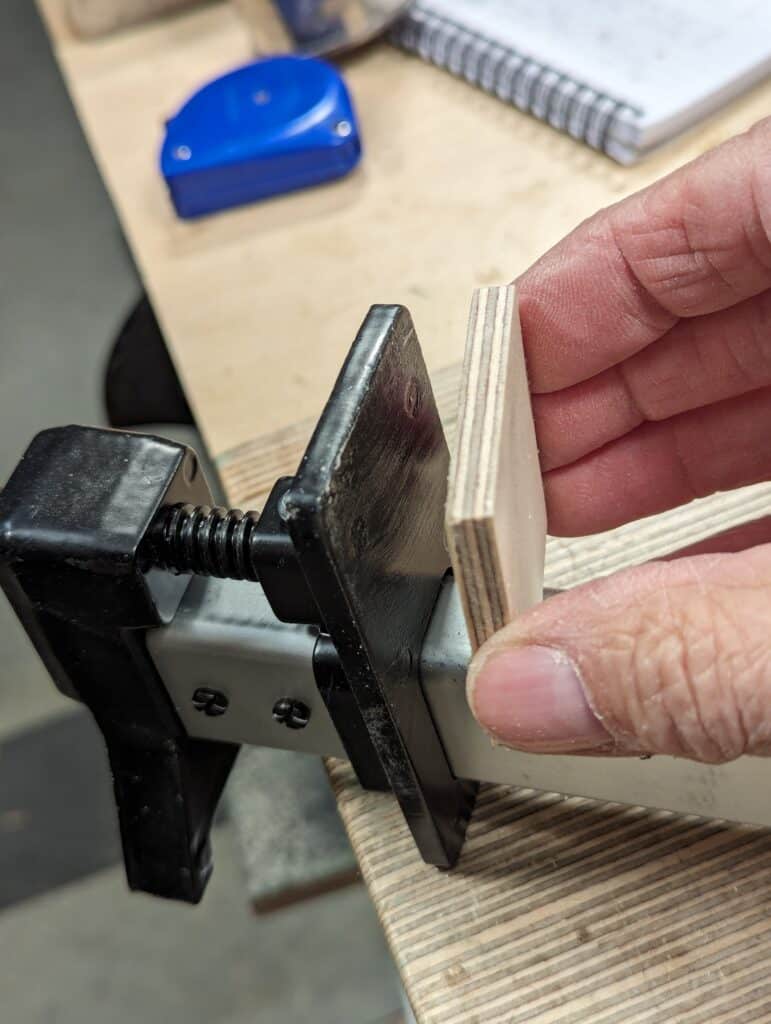

On all of my clamp heads I prefer birch plywood facings and I added them to the Rutlands. This cushions the clamped wood very nicely and provides an absorbing feel when clamping.

The fixed winding handle instead of the ‘tommy’ bar version might be a problem on occasions. It does affect my clamp-in-a-vise method of work holding because the handle hits the apron or face of the bench. But there will be many ways around that so not really an issue.

Moving the clamp along past the bench end will solve 90% of issues.

A drop of machine oil resolved any sticking issues as it does on all clamps from time to time.

As usual I will make my disclaimer. Rutland surprised me with the quality and price of their clamps but I take nothing from them and neither did I forewarn them of this blog. The only reason I mention it now is that people are always looking for a good clamp and here it is.

Paul,

I wish you’d written this a little earlier! Toward the tail end of last year, I picked up some sash clamps from Amazon (£60 for 4 I think, I bought 8), and they were of the thinner walled variety that you show. The threads on them aren’t great either. That said, with the wooden insert, they work well enough for most things. I actually looked at the Rutlands ones too, but thought I’d go with your prior recommendations. I still need to pick up a few longer ones for those occasional jobs, so I’ll likely return to Rutlands for those. I bought clamps from them about 15 years ago (I was persuaded on the heavy variety, as per your previous blog post!), which are still in fine working order as expected. I had always considered Rutlands to be a purveyor of lower end goods, but I’ve generally been pleasantly surprised by their products when they arrive, and the service has also been good.

Thanks,

Rico

I am a fairly incompetent DIY woodworker but enjoy working with quality tools. I follow my grandfather’s advice, first told to me over 60 years ago,

‘Buy cheap, buy twice’.

I have been a customer of Rutlands for many years and have always been delighted with the quality and value of their products and the excellent service.

I’ve been using 4 Juumas for a couple of years now. The slip-on black rubber cushions don’t hold over time (and are too hard so leave a mark on softer woods) but that’s easily fixed with a plywood patch. I don’t have wooden inserts and they work fine, wish I bought more of them before prices started to soar.

I also have some el cheapo tinfoil toolzone clamps. They are fiddly to set up (https://paulsellers.com/2017/01/screwfix-sash-clamps/) and the clamp head does damage the bar a bit if you don’t round the moving head with a file where it hits the bar so you’ll need to do this before first use (found out the hard way), but once set up they’re not too bad. They do what they need to do for me.

What would make me happy though is a system where I can transfer both heads between bars so that I could get the longest version and then cut that up in various sizes, attaching the heads where needed. Scared to try that out as the fitting is wobbly as it is..

Being able to extend them would also be nice, I tried Pauls method but that didn’t really work well for me.

I know, can’t be stingy and expect the best of both worlds 🙂

Paul, howdid you attach the birch plywood facings to the clamps?

Contact cement. Apply to both faces, wait till touch dry and press on but leave a slight gape between the bar and the ply edge.

Thank you Paul for this. Contact cement. Why didn’t I think of this. I had tried CA glue, double sided tape, etc but could never find a solution that worked. CA glued ones would pop off and the double sided tape ones would slide. I finally glued on some thick leather to many of mine and that seemed to work but time will tell.

I use ordinary construction glue, still holding after 3 years

Construction glue is not a glue type. Can you maybe expand on this?

Here in Australia it’s sold as Liquid Nails, or the cheaper stuff in my hardware store is just called Construction Adhesive. I’ve been using it to glue down some Jarrah flooring to tile underlay, works well.

I wondered that too. Double sided tape perhaps? The thin stuff. I’ve used hot glue in the past but in cold winters they can snap off and come loose easily.

I tried double sided tape as you described, but the plywood pads tend to twist out of line. Probably because the adhesive becomes a bit soft in warmer weather. I’ve just ordered more clamps earlier today as it happens, before I’d seen Paul’s latest blog. I’ll be trying the contact adhesive as he suggests next.

I’ve tried double sided tape. Short term they work but there is a slight angle on these faces and over time, the wooden pieces move.

Last time I replaced mine I used Gorilla glue and moistened to wood a bit to make glue set up. So far this has been the best yet.

Andrew,

I have used the double sided tape, clear, on mine. They have held so far. Been almost a year.

Carpet tape (might be called something different in the UK) is two-sided and very sticky. The first time I tried using two-sided tape in the shop I got some from a stationary store, and the adhesive was about the same as the adhesive on post-it notes (duh). If you live in the US, shop for “carpet tape” and you’ll get the right stuff.

“Can never have too many clamps”

Someone had to say it.

I bought good quality clamps in the 90‘s. Every single one from that era is still operating flawlessly.

Within the past 5 years, I have purchased some quick clamps. Some were name brands, and some had no names that I could see. (eBay or Harbor Freight) Every single no-name quick clamp has broken, or at the least will not tighten anymore. That was my one and only Harbor freight tool purchase.

I have owned four of each size Rutlands clamps for a few years and can attest to their robustness. They were plenty good enough to clamp up my workbench when I made that. I also was unfortunate to own a couple of Silverline clamps, for about 15 minutes, then they went straight back. Useless, horrible threads, flimsy and twisted the moment force was applied.

Paul,

Never underestimate the power of your blog. Rutland now have and offer on a set of four of their 600 (24″) length clamps for £40.

https://www.rutlands.com/products/aluminium-sash-clamps-with-feet-600mm-pack-of-4?_pos=4&_sid=2a01bdc18&_ss=r

By coincidence I’ve ordered some today!

I saw the offer too, and even though the price doubled with shipping cost to Australia still was competitive, but then when I went to checkout, the price reverted to full price. I can but watch and wait.

Hi Richard,

Looking at the Rutlands website today, the 4 pack is $86 AUD (down from $150 AUD) with $82.29 AUD shipping so the discount appears to be working today. I’ve been buying the IronGrip brand from Sydney Tools at $19 for the 610mm. The sidewall on the ones I bought is 1.4 mm. They seem to be OK for the things I’ve been clamping – small table frames. Haven’t had to do a table top / panel so can’t comment on the suitability for those.

Hi Michael, thanks for the note, the day after my comment I saw the price reduced for May sale and thought that he who hesitates…. DHL saying they will be delivered tomorrow. Thanks for the comment re IronGrip had not seen them before else might have gone that way, these will hopefully be used for a benchtop when I can find some decent timber, was thinking tas oak

I bought the universal bar clamps some years ago and have been really happy with them.

You can buy them in 5 pair sets which brings the price down somewhat. If you can’t afford that you could go in with someone else and split the order. I’ve also bought some Bessy clamps, they are really expensive but I only use them when I run out of my other clamps. I have very good finger strength but I can’t get the round handled bar clamps tight. My fingers keep slipping on the wooden round handles and then I can’t make the quick adjustment mechanism work right. I’m always fussing with them in the middle of glue ups which only adds to my anxiety.

Tom, try a smidgeon of O’Keefe’s Working Hands cream while you’re waiting for the hockey stick tape. Very little is needed and it gives your hands the grip of a gecko!

Hope you’re feeling better. As always great information

The first Sylverline I got had 1.2 mm thickness; the second batch was 0.86mm thickness and a softer aluminium so the notches for the moving jaws would deform under clamping stress.

I had the same issue, by the time I realised how bad they were I had already “fettled” them, so although I should have returned them I felt my modification would make them suspicious. I vowed to avoid them and switch back to all steel, cheap ones. The fact that the steel ones were then cheaper helped the decision. They have been fine, except that the pin holes were too far apart, but easily fixed by drilling intermediate ones.

I think that the real issue is that most manufacturers, wholesalers and retailers don’t use their products, so don’t realise just how bad they are. If I was being cynical, I might suggest that they have the attitude, that it is selling well so we will cut the quality.

Glad that I bought my genuine Record (steel) sash clamps 45 years ago. yes heavy, but haven’t had any problems with them.

I have two thin-walled clamps (20″ capacity) without any wood inserts. Would it be beneficial to add some wood to the inside of the bar? If so, does the wood type or density matter? Is hardwood recommended over soft wood like pine or fir? Thank you.

Not hardwood. Definately good to do and just use any softwood, stud wood is what I go for, any old pine.

Thank you for that tip. I just picked up these previously-owned clamps and have not used them yet, nor have I previously owned this type of clamp so I am not familiar with their characteristics. I will definitely add some wood inserts to them before using.

I bought a pack of 4 clamps from Rutland late last year. They have been really good to work with. They seemed to be of fair quality but I’m really pleased to now know they are really good quality. Thanks for the post Paul.

Here in the USA… Boy, the 24″ Rutland are in the 4-pack for $53. I have enough 24″ clamps, but I wanted a set in the 12-16″ range just for easier work on the benchtop with small projects, so I was going to cut them down. I put two 4-packs of the Rutland clamps in the online basket, hit the shipping button and was greeted with a $78 shipping fee (2-3 days air shipment), no other choices for lower cost shipping. Oh, well.

I measured my older Harbor Freight clamps and the sidewall is 1.9mm, it works pretty well but could benefit from Paul’s wood stick trick. The latest HF version is much thinner than those, not worth buying in my book. I grabbed one of my Dubuque (“Universal”, as Paul shows) sash clamps and the sidewall is 2.9mm thick. I’ve never needed sticks in these ones, but they certainly would not hurt.

Dubuque/Universal are probably the most affordable, in the USA, from HarryEpstein.com. Other retailers sell them, too. Their prices are about the best I’ve seen. $29.75/24″ up to $40/72″, 5 versions in 12″ increments.

https://www.harryepstein.com/search?q=dubuque+clamp&options%5Bprefix%5D=last&x=0&y=0

Here’s a neat newspaper story about Dubuque Clamp Works from 2014-

https://www.telegraphherald.com/news/business/article_4c1b143a-bff2-5dd4-869c-47c8a63cff52.html

today 29/04/24 Rutlands pack of 4 600mm clamps are you aware that £70 you £40 plus £7 delivery

predictive text grrrr

£70 down to £40 plus £7 delivery

Paul, the topic of packaging “scam” is one of my pet peeves in how consumers are being misled or cheated. When I go grocery shopping and see a product package with a new exterior design and a label proclaiming “New look, Same great taste”, I’m already leery of what the “new look” is. Often it is just a new look of packaging, but sometimes part of the “new look” is a reduction in content weight, and the new razzle-dazzle packaging design to divert your attention from seeing the new lower product weight. Yes, it has the “same great taste”, just less of it.

Also, here in the US, the pictures on frozen [microwave] food products usually shows something that is no way close to being what’s inside. Manufacturers usually have a well staged, delicious looking large portion photo on the package, and as long as they have the magical caption “serving suggestion” somewhere on the product photo, the deception is legal.

Your tip for adding the wood to clamps was brilliant. It enabled this new woodworker to outfit my workshop with a variety of clamp lengths, without going into debt, from buying the more expensive versions.

Not sure how far this term has spread, but US has taken to calling this effect “shrink-flation.”

I’m glad someone asked about the fixing of the pads. I’ve been using double sided tape and the pads invariably twist off.

I did use double sided tape in the past and it worked fine but it’s not the tape you use for paper. The US and the UK naming of things is not alwqys one and the same . . “two nations divided by a common language.”

Rutlands still offers the sash clamps with wider stance and the “fixed winding handle” shown in your pictures, but they also offer sash clamps, apparently built with the same standards, with a somewhat narrower stance and sliding tommy-bar handles, at a slightly lower price. A 6-pack of the tommy-bar clamps currently costs $110, plus shipping ($58.79 to my address on left-coast USA – YMMV) and tax ($14.85), so total is just shy of $184, or $30-&-change apiece to my door. Seems like a decent price for a quality clamp. The ones with fixed handles are running $93 for a 4-pack, plus shipping and tax, so about $37 per clamp – also a decent price.

Yes. I saw these but wanted to see how I felt about the ones I bought. If I could have bought just one i would have gone that route beut, hey, you only need so many clamps.

My favorite bar clamps in the US are Dubuque Clamps. High quality, heavy materials and great threading. You’ll find cheaper alternatives at Home Depot but the Dubuques are worth every penny. I buy one whenever i have a few extra dollars and will keep doing so. Thank you everybody for all the great comments and information.

Agreed! They are the finest clamp made – simultaneously light & robust.

I’ve just taken delivery of the “600” mm clamps from Rutlands, and, unlike others, you do get the full length…

Without the thin wooden pieces attach that most of us do, the distance between the face clamps is actually 620mm.

So longer than my selection of other ones… And with the feet they are overall a bit wider as well…. So a new hanging rack is next project!

Matt

My problem has not been the wall thickness, but the clamping head, in particular the head that is driven by the screw. It cams over, digs into the bar and makes it impossible to apply pressure. This can happen even with the clamp empty, so it isn’t from flexure of the bar. It is from poor tolerances and perhaps from aluminum that is too soft. The branding on my clamp is, “Pittsburgh.” I still don’t understand why the fixes I’ve tried didn’t work. I’ll try again.

Another example of dumbing down products: It may be impossible to buy a carver’s screw. Until the last couple of years, one manufacturer still sold a decent one. All the others were spoiled by one of two things. Either they put a wood screw thread on the end that goes into the work (rather than a snail) or they used a non-acme thread. Two-Cherries made a suitable one, but in the last couple of years they replaced the acme thread with a finer one. While it still works, you must suffer all the extra turns to clamp and unclamp. I find I must do this enough that it is frustrating, especially when the change was pointless and done either out of ignorance or to save money. I think having wood screws for the end that goes into the work is poor because the thread is too coarse. A snail can get more bite with less depth. Oh, they also cheaped out on the wing nut, which used to have a (square) wrench built in for driving the screw, but now does not. The wrench is a separate stamped bit of waste (or wasted) soft metal.

Just to clarify, regarding the acme thread vs. finer machine thread: That is the main, long thread along the shaft that you run the butterfly down. So, two threads: the thread that goes into the work, which I find should be like a snail, and the thread for the clamping butterfly, which I think should be a fast Acme thread, not a fine machine thread.

In college in 1988, I took a class called “Mythologies of Western Europe.” It was a fun class taught by an old Jesuit priest, Father Swain. We had books we had to read; the class lectures were him telling us the stories. It was a fun format but the exams were challenging.

One thing I remember to this day was Father Swain telling us also lived in a mythology. He said our mythology was that as time progressed things would get better. To prove the point, he gave a number of examples including comparing today’s music to say the music of 200 years ago. I had to agree with him, we were indeed living under a mythology. Have never forgot that lesson.

I love my Dubuque Clamps as well, they are the best I own.