Jack’s Heart Opens

From the dim light of a wintry grey sky, Jack’s pencil hovered over the drawings on his workbench dipping up and down between finger and thumb. I had gained great credit for achieving something none of my co-apprentices had ever achieved. Jack could now walk from one end of his bench on a clear duckboard that hitherto had been buried and hidden for years beneath inches of downtrodden shavings. Though Jack had never seemed disturbed by the dump he’d allowed to accumulate year on year, it was evidenced by his asking me to deal with it. The trick was to not get in Jack’s way, not to disturb him or his various trains of thought. His unwalled space was the inner sanctum into which few ever trespassed. It was his place of meditation where the architect’s drawings must be translated into three-dimensional products of wood to fill openings, gaps and spaces hitherto indeterminate, unbuilt and far from occupied. The drawings were the outlined intent of men that drew but never made. Mere lines on sheets of blueprint must yet be transformed by workmen handling saws and planes, chisels and mallets. This was Jack’s power to transform. The men scattered at their benches around the shop obeyed the lines placed on the wood by Jack’s pencil alone and cut and chopped to them meticulously. From the day and sphere of now-cleared spaces, I caught Jack’s approving smile with repeated regularity. It was the first time in a year since I started working that I felt, well, approved. The others noticed it too. In any society based on crediting others with approval, meritocracy, there always exists the jealous and envious. With these two demons present and living side by side, there could never be any kind of true peace of mind. While Jack gave me preferential approvals resulting in small tips and helps where possible there would always be some other to stir up resentment. The worst of these came from a 45-year-old joiner called Merlin. I’ll tell you about him sometime when I find time. Wretched man!

My collection of hand tools had grown carefully but steadily over the year so far in my apprenticeship. One day, sweeping around Jack’s bench, I stopped to look at Jack’s tool chest, the one I had uncovered in the sweeping and cleaning I had done. I’d registered seeing Jack’s more approving manner towards when I had cleared his accumulated bench mess but then the more when he realised my interest in the vintage tools dotted in different pockets of men’s toolboxes around the workshop.

I remembered Jack’s surprise in my uncovering the tool chest and here I was again casting my eye towards it once more. How he seemed to have forgotten it was a surprise to me but now that I myself am older I understand better how our minds work. He seemed to more have just, well, lost track of it if you will. That’s all. When I’d given his space the good clean up it needed badly I was too busy to have taken in all of the details surrounding his bench. I had however glimpsed some of the ebony elements contrasting the brass and steel on tools in his tool chest when we’d moved it around a little. But now, with the box closed and drawers shut, I noticed the name had a well-worn ‘R‘ before the slightly more prominent ‘.J.Collins‘ in the upper right-hand corner of the chest. I had assumed the .J.Collins bit only. The calligraphied name was placed there in fine brush strokes with an elegance fit for something more extravagant, more grand, maybe a sign outside a noble home of the landed gentry, a National Trust property. Yes, the name was clear so I queried the R with Jack. “My grandad!” Jack said. “He made the box when he were a lad. When he died it went to me dad and when me dad died me brothers argued over how to split it so I offered them a good price split between ’em for it and here it is. Royce Jack Collins, R.J. Collins. Nice, innit?”

It was Friday afternoon when Jack and I opened the tool chest. Beneath his dust-covered glasses and his bushy eyebrows his eyes were lively and bright. I say tool chest because this wasn’t just one of the more vernacular boxes made from ‘deal’ — the common wood used in making the five-panel pine boxes with four plain sides a lid and a bottom. This chest was different, quite stunning. Dovetailed corners, yes, but more, much more. Jack’s old hands had taken him through World War II. The thick veins stood out from the pale skin, knotted rises mapping his work-life in places but still muscled beneath the wrinkling skin. Jack had seen and done things that had caused the drink and the drink caused his hands to tremor all the more. The recurring memories for some men I worked with had resulted in sadnesses and losses they always kept inside. “Cannon fodder we were mostly!” Jack once said.

The lid was thick-rimmed, heavily strong and solid and reinforced all the further with thick steel corners screwed in place over the dovetails. The lock, hinges and escutcheon were set to stay and stay they had for some hundred years. Jack thought it to be made sometime around 1875. “Mebe more!” he said. He lifted the lid by an inset brass indent in the fore-edge. The suction made it seem stiff to lift but it was the tapered rim that caused an air seal; once the air seal was broken it lifted up against the chain-link stay and leaned back onto the taut links. His rough hands reach inside to lift out a plough plane with screw stems. “Boxwood stems.” he said. There was a filletster next to it with cast brass end enclosures, sand cast and then hand filed and fitted to the hardwood stems before being cross-wedged permanently in place. The various cutting irons for the plough were rolled up in individual pockets but dampness had added a thin surface misting of rust that had begun to discolour the coarse cotton fabric.

Do these work? I asked, inquisitively.

“Course they do! Work great. Daft bugger!”

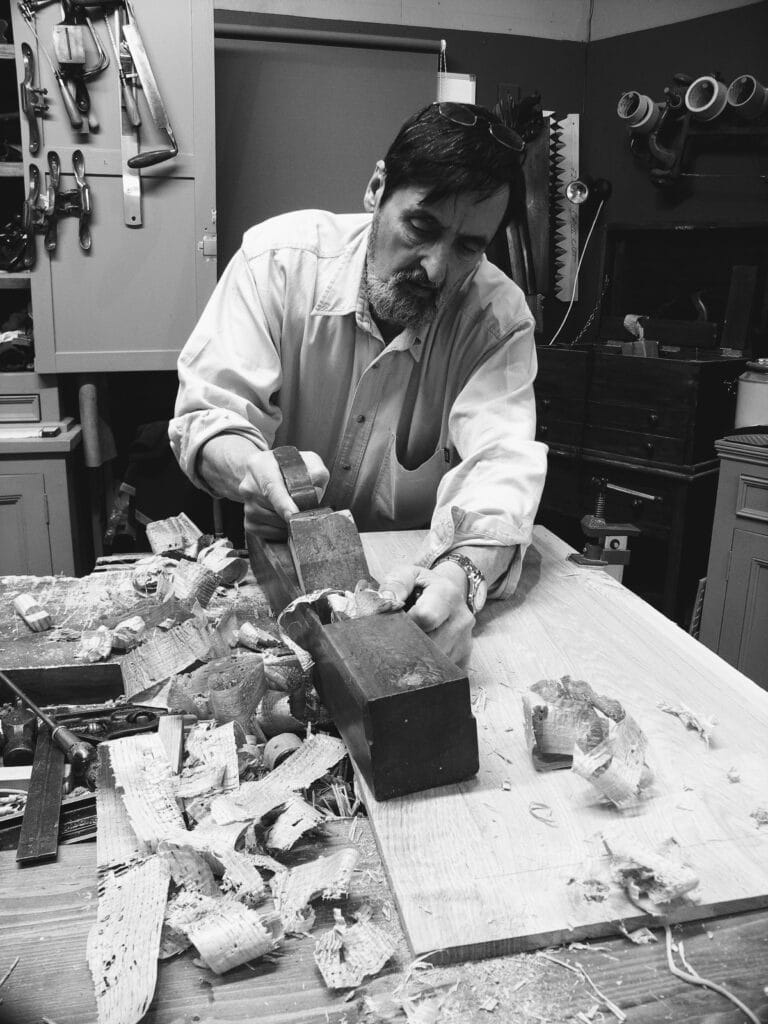

Without more ado, he had the plough out of the chest and pulled a chunk of redwood pine to clamp in the vise. Before I knew it a 3/8″ groove had bottomed out on the internal brass stop down a two-foot length. Equally fascinated were half a dozen men and apprentices behind me gathered as a group to watch. A couple of the older men knew but the younger ones were surprised.

What amazed me equally though was the transformation I saw in Jack. His whole face had taken on a brightness I doubt that any one of us had seen before. His whole body seemed somehow younger; he’d suddenly sprung into action with his voice infusing us all as if something ancient had been unlocked from deep within him. It was at this point that I realised his abandoning of these brilliant dynamic tools was never from choice, never from them not working and never from them not giving excellent results. Even then, at barely sixteen, I saw that they were abandoned because they just couldn’t keep pace with the industrializing of woodworking. Specialisation had gradually but steadily eaten away at craftsmanship and had taken over something so much deeper. Two World Wars had been the vehicle that took away men and women, yes, but it had also been the vehicle by which mass-making would replace it. The continuum by which the Industrial Revolution would become the Technological Revolution embracing a technology yet to be born. He’d been forced by the different generations of soulless bosses chasing profit to adopt machine methods only. As he placed the plough plane in my hands he transferred to me a belief that I could take a different path. It was exactly what I needed to know. A door opened at the back of a fur-filled wardrobe into the wonderland of real woodworking.

Placing the plough plane to the wood, feeling the edge of the iron bite to engage in the cut, I sensed the union begin as I pushed the plane forward. A new revolution began. Up until that point, I did not know it was possible to still work in the abandoned ways and the opposition did not come from any worse an opponent than my peers right there in the workshop. Just what was it that drove them to jeer and mock what then seemed to me such a loveliness even some of them had never seen fully? They held nothing back in the unfolding weeks ahead. They simply seemed to hate my love for what I was engaging with. My pathway to discovery was just beginning. Those tools, that wooden box, the drawers in mahogany and oak that glided in and out with so small an effort though weighed down with many tools; chisels and gouges, wooden spokeshaves, scrapers, hand-made scissors and things I’d never seen before. In those opening moments when the case lid lifted in an arc and the history of all woodworking hand tools seemed to nestle there in the silence, in the dark of its inner chambers and partitions was amazing to me. In the opening of that single chest of tools, my life began its changing. So succinct for me was that I welcomed it to become mine. Not the tools and not the box. No. It was the way of working. I knew then that it wasn’t what you made that mattered so much as how you made it.

It was as much the fit in my hand that impressed as the shaving spiralled up from the throat and parted off at the end of each long stroke. Everything came together in the first stroke even though the plane seemed far too big for me. Planing with a number four Stanley bench plane had indeed equipped me but it was the expectation that surprised me in the repeats of successing strokes. Imagine the thumbing of the pages of a book like a flip book where images shaped move as stills but look like a moving picture of old. This was how everything impressed itself in my brain. The indelibility of such happenings are seeds of vitality. It wasn’t so much Jack volunteering into something but more my questioning that stimulated latent memories of a time when his tools and his work engaged with the true tools of the trade and craft he had been trained and raised in. I think 99% of it came from somewhere within me, the innate calling to the future. Conversations of depth and substance often if not always start with some kind of basic question. Questions alone can spark new life in old men and knowledge passes from one ancient to a new generation. Sixty years pass and a man matures with rootedness as a tree that outspreads huge branches to reach around the world. What happened with Jack reaching me and me him can cause me to share similar tools and matters of real woodworking and in a matter of minutes others. In my world now I often reach 20,000 people intrigued by ancient methods in a matter of only a few hours and my craft now lives on in the lives of dedicated woodworkers like myself known as amateurs — those who do it because they love it: Amateur from French amateur “one who loves.” So it is with my recessing hinges for 50 years when only a handful saw and now over a million, no, two million and more if you include the whole series, watch me make a workbench from studs on a grassy lawn in my backyard and people feel that they too could do such a thing.

Paul

I have always kept my chisels in a rack, the present on is in a tool cupboard. Although my growing collection has outgrown the rack and a few now sit at the bottom of the cupboard. I have always wondered why you keep yours in a box? Was that how they were kept in tool boxes, like the image above. I suspect the reason I use racks is that that is what I saw at school, and have a distant memory of the virtually retired village carpenter (from my youth) who had some hanging on a board on his workshop wall through leather loops nailed to the board. No doubt the leather was an old piece of horse harness no longer fit for purpose.

Now his workshop and the blacksmith next door are an engineering workshop.

I have never really had a wooden toolbox, so perhaps it has never occurred to me to use a box, even though many of my metal working tools are in 2 metal boxes that were presents in my youth.

Toolboxes and chests were mainly for the lesser-used tools. In the past, cabinet makers (furniture makers) like myself had tools they needed but could ill afford to give up valuable bench space to hold them on the benchtop. Wooden versions of planes were considerably larger because of the blockiness. Plough planes, fillister planes and such were three times bigger than metal versions too. I have never liked racks of any kind and therefore seldom use them. My very worst mental image is of hand tool workshops where pegboard is used for holding tools on metal rods with the outlines of the tools drawn around them. I realise that this is mostly used in more institutional and industrial workshops to resolve the displacement of tools used in multiple occupancy workplaces. I don’t like benchtop racks that twirl either. Tills and trays work really well for me. Something I can pull out to place near to hand and that holds my chisels, screwdrivers and such. I have a long well on the far side of my bench that holds about a hundred smaller hand tools ranging from chisels and gouges, putty knives and scrapers on up to raps and files and a section dedicated to different gauges. I have about eight gauges in fulltime use. ~whereas when we start out we might own half a dozen chisels, additional ones come along for different reasons and different uses. I think I currently have about 30 chisels on my bench.

Thanks for the time spent on the long reply Paul. I keep thinking of rearranging my workshop to be more organised than the random way it has evolved. I fear that I also have a similar number of chisels, some I have bought cheap in junk shops and restored.

The first backyard workbench series was my first, and still my favorite. Oh, the techniques Paul taught me in that series!

Good morning Paul,

What Jack did for you decades ago, you have done for us!

You have opened an unknown world of experiences and joy.

God bless you.

Tim

Wonderful story, Paul. I really enjoy these lovely recollections of yours into your apprentice years, and the history behind the mentors you experienced.

I have a smaller and quite old toolbox that my long departed Dad built to hold his important tools at his work as a master machinist. He was also a capable woodworker and carpenter as well. I am going to build a traditional English tool chest this year with trays to house my most used tools. Just finished making the first of your wooden router plane design from Maple. Works perfectly.

Thank you for all of your teaching and tips. Even at 80 I am still very active, and always want to learn to new woodworking methods. This is the reason why I have subscribed to your Master Class series since its inception.

Cheers.

Michael O’Brien

Jack sounds like quite an enigma. On the one hand having to be almost unapproachable so as to maintain a distance between himself and the people he doled out the work to, but at the same time a softer side that was quick to recognise a genuine love of woodworking from an apprentice.

To interpret architect drawings, and from them create work tasks for the work force, can’t have been easy. I was curious, did he ever misinterpret them resulting in giving out wrong instructions? I guess that would have been rare if it ever happened, but how about a worker not following his instruction accurately? What would the reaction have been in either case?

Posts like this make me yearn for a bygone age and wishing, in my youth, I had forsaken university for the life of a craftsman. I derive far greater pleasure from creating in my workshop than from creating in my job as an engineer. Thank you, Paul for keeping the art of real woodworking alive!

ah, another engineer like me who wishes he’d done something else.

Beautifully written story. I was hoping to see a picture of the actual chest, thinking Jack could have left you in possession of it. Any idea where it could be now?

Thanks so much for the recalled memory of your past. I too love to read about your apprentice days of years gone by. I am about the same age as you, but here in the USA there were not apprenticeships when I was a teenager. I was very fortunate to have an awesome shop teacher for my 4 years of high school. That is where I first put my hands on a Stanley # 4 & 5. Little did I know that decades later I would be reunited with hand tools and traditional wood working at a much greater degree when one of my grandsons took an interest in it at 12 years of age. That was 9 years ago. That is also when through the power of internet I found Paul Sellers. I have learned so much from your videos and enjoy passing the knowledge along to my grandson.

I hope someday you will publish all the stories that you have shared about your apprenticeship years. It would make such enjoyable reading. When I read your stories like the one you just posted, my mind envisions the shop, men surrounding you, and of coarse George, leaning over to tell you something quietly, just between the two of you.

So hopefully you will add your apprentice years documentation to your bucket list of things to accomplish. Looking forward to the read.

Jim Light, Goshen, Ohio USA

Thanks Paul for the wonderful post. In the 1990s, I watched woodworking shows on PBS (all pre internet). I was in my 20s. The New Yankee Workshop with Norm Abrams, This Old House, and Roy Underhill’s Woodwright’s Shop were huge shows. What frustrates me to this day, was I really liked Roy Underhill’s show with the hand tools. For some reason, I thought he was showing how it used to be done rather than how it COULD be done. I distinctly remember one episode (or was it two) where he showed a router plane and a plough plane. I was blown away by the geometry of the tools and how the differed from a normal hand plane and how you could get different cuts. I wish I could have seen that I could still use those tools. It took me till 2014/2015 before I realized they were still viable approaches to woodworking. I very much enjoy my career as chemist (though wish I had never left the lab as I very much enjoyed using my hands in the lab). However, I could have been woodworking a decade earlier with hand tools. Better late than never I guess.

I enjoy very much the stories of your apprenticeship. My young working years were spent in a planner mill. There was no apprentice program but many good mentors to help along the way. I have a work bench of your design in my workshop as a result of that video of you making the workbench in your backyard and have been watching you blogs and videos ever since. Thanks for all you do.

when i first started working, many of the men who were in charge at the time had seen combat in ww2. it made them difficult to work with at times, as they were quick to anger and hard to understand. as a teen i could not comprehend what they had seen or done. after all the movies back then were very sanitised and only the enemy got hurt. it is only now as an older man who has seen and experienced a broad and varied life, that i can get an inkling of what they carried with them.

I guess we don’t always know how people influence our lives until we have time to reflect on what we have learned from them.

What an amazing age we live in where we can pass along what we have learned in our lives through the technology of the internet. All you have to do is listen and absorb the lesson.

Great comment, Tom. I feel the same. I love the Internet for bringing me The Sellers folks and the pinnacle of woodcraft and people like you. Because of PS we’re going to have a renaissance in hand tool work, not just wood but blacksmithing, jewelry making, bodgering, heck even bushcraft and those kinds of hand crafts. Just look at the Youtube copycats of the masterclasses. They’re everywhere now. Not as good mind you but still, not everyone is Matisse. Me, I’m like Goofy with a chisel, but I enjoy it immensely…so what! And a tiny bit better over time at making stuff and that’s a big part of the joy of it. I get useful basic stuff I made. Still can’t saw the winding sticks project worth a darn though. lololol.

My maternal grandfather, an engineer, had sad demeanor. When I was perhaps 5 or 6 years old, I remember telling him I had a surprise (that I don’t remember) and he, a WWI veteran of the trenches in France, saying, “There isn’t much I haven’t seen.” Like the words of your friend, as I’ve grown older, his words have gained meaning.

I keep my treasured hand tools in drawers, which buffer the temperature swings in my woodstove-heated (often unheated) shop. Last spring when outdoor temps in Michigan went from frigid 20s to humid 70s in a couple of days, the condensation in my shop was horrifying. My stationary tools suffered a little, but they were well waxed. I sort of forgot about the hand tools. My good chisels in a box inside a drawer were fine, but my hand saws suffered badly. I have become religious about using my patented Sellers rag-in-a-can since. Those old tool boxes were well sealed and I’m sure the tools were kept lightly oiled, like your friend’s, and so did more than merely organize the many bits of a woodworkers life.

Reading this post I was immediately reminded of an English romantic poet I only discovered a few years ago…over 50 years now from my “English Major” time in college…who was essentially ignored up until about 20 years ago: John Clare. He was the essence of a romantic poet, had a brief time of acclaim, but who died in an institution and was forgotten by almost everyone, certainly never mentioned in my college studies. Clare was a keen observer of all around him, and a prodigal at sharing his observations in poetry. That’s how I see you, Paul, only I hope you are never forgotten in your marvelous descriptions of your craft and the world that surrounds you. Thank you for all you do and all you show and teach us!

Dear Paul,

What a delightful story. I had a similar experience when I was a young organ-building apprentice in Perth, Western Australia. There was an old organ builder, Mr John Larner, who had run his own business which had failed in the recession in the 1990’s. He died a few years ago now. Anyway he worked on and off for my boss, and was much like Jack. He took to the drink and always seemed to live his life in his own thoughts. One day I visited his workshop at a place called Yarloop, Western Australia. It was located in an old steam operated lumber works. It was like walking back in time to a bygone era. I was immediately fascinated that old John, who was a quiet and private man, seemed so different in his ancient looking workshop, filled with curious and equally ancient looking tools. I asked the same question; “how do these old things work John”. He took up a great big old lump of wood, a jointing plane, and began sending it over a lump of deal pine. The sound and smell of the shavings spilling out just enchanted me. Anyway, I visited him very frequently in subsequent years, and it was from old Mr Larner that I began to learn how these old tools worked. One day, after having finished a job for him, he said “son, see that old box under the bench? Go pull it out. It’s for you”. I was amazed. When I lifted the lid, a whole box of assorted wooden planes presented itself. Moulding planes, tongue and groove, plough planes, wooden spoke shaves etc etc. I asked him where he got it from. “They were my great grandfathers. He was a cabinet maker for the shipwrights in Albany, WA, in the late 19th century. They’re yours now”. I was astounded by his generosity. That act of kindness opened a whole world to me. Slowly over the years I began to clean off the dust and mould and sharpen the irons. Every single plane worked beautifully. I use them all the time. Some of them must be very very old. I will always be indebted to old John Larner, and will always be grateful to him for sharing his knowledge, love if woodworking, and his great grandfathers prized planes.

And what I didn’t learn from Mr Larner, I now learn from you Paul. In fact I have learned more from your videos than I did as an apprentice, and from fourteen years in the organ building trade. Every question and curiosity of mine finds and answer in you. Thank you Paul, and thank you to old Jack Collins.

Did the Yarloop fire raze his workshop to the ground? Maybe you inadvertently saved the tools. I would like to think so. PS I live in Mandurah.

Hello there Roger- yes it is certainly true. All those workshops and beautiful steam machines lost! The patterns in the Pattern Maker’s Shop for the locos, all gone. They were remarkable! Mr John Larner’s workshop went up as well. Those tools would have suffered the same fate. They’re now right here, with me, in my workshop in Sydney. Mr Larner was never the same again once he lost his workshop. His wife passed away soon after, his livelihood slipped away due to his advancing years, and then he too just faded away. I was lucky to have met him when I did. I think of him whenever I open his great-grandfather’s tool chest.

“… watch me make a workbench from studs on a grassy lawn in my backyard and people feel that they too could do such a thing.”

I felt that I could do such a thing.

And I did.

Hi Paul,

That was one of the most engaging posts I have read to date. I was transported back to my earlier years, surrounded by older craftsmen who didn’t seem (at the time), to have much time for us younger people who were inquisitive, eager and thirsty for knowledge. Little did I understand at the time that those seasoned craftsmen also had their own mandate to produce quality work in a given timescale, and that distractions were a luxury not many could afford, as much as some of them would have wanted to. I understand that now that I am in their shoes, with a caveat that I do share my knowledge with anyone who is interested in learning. Todays youth are tomorrows craftsmen, and craftswomen.

I look forward to reading your memoirs with more tales of George, Jack and many others no doubt when it is published, as I am sure thousands of others are too.

Thank you.

Dear old Jack.

If only he knew that his legacy is a whole machine generation or two reconnecting with true craftsmanship…. Or perhaps with you he was precient?

Happy New Year, Paul. Pardon my familiar language, but after a couple of years of watching you on YouTube and Woodworking Masterclasses, I feel I know you. I loved this story. It has a wonderful elegiac quality about it that evokes a longing for times past. As someone with a degree in literature, I always appreciate good writing! I have collected quite a few lovely hand tools: bench planes, plough and router planes, chisels, braces, etc. and am trying to decide how to store/ display them and have them ready at hand for use, but well protected from dust and the elements. I watched your Masterclasses tutorials on the tool cabinet and toolbox builds and am betwixt and between concerning which to make to have by my workbench in my garage workshop housing my tools. What would you recommend as my first tool storage solution?

Paul,

That was one of the most uplifting stories you have told and the comments confirm it has touched the souls of many woodworkers. There was a theme emerging that many wanted to be woodworkers but ended up being engineers, I am also part of that group. My godfather was a full time woodworker and I used to go to his workshop and watch, not often but enough to take in the dim working conditions and the smell of the shavings. He, like others mentioned in your tale and comments, noticed my interest and gave me a well worn Lewin plough plane and three cutters. One of the cutters was home made from an old file and worked just fine. It seems we woodworkers want to pass on tools to future generations to be used not displayed and you have had a great part in this. Thank you, Keith C

any idea of what may have happened with Jacks toolchest?

No. I lost contact when I started my journeymanship. He retired that year too.

Paul, last year I completed your English Jointers Bench, using (almost) exclusively hand tools, using your plans and inspiring videos…and other plot posts and other videos to purchase and restore vintage tools. Your post reminded me of the precise feeling I had when I first used my grandfather’s Stanley rabbet plane and no-name wooden plough plane to fit the tool well…feeling so very deeply connected to the past.

So you serve as a Jack for millions of us…with a significantly more positive spin, of course. Many, many thanks for helping each of us along this wonderful journey.

I love your memories. Please keep telling them.

There must have been something about the name “Jack” that made men be curmudgeonly on the outside. Your description of Jack reminded me of my stepfather, Jack. He was gruff to people, often sounding like the WWII Air Force Sergeant that he had been. But once you got to know him, he was quite gentle.

I learned a lot of my woodworking basics from him. He tried to get me to use hand tools, but being a modern teenager I opted for the power tools instead. Now, I am collecting various hand-tools, and re-discovering the tricks he taught me decades ago.

Yep. I blame you, Paul! I saw that on-the-studs movie series and a light came on.

I now have not only the work bench, but a fine collection of nice hand tools – I am starting to venture into the more specialized areas now, from pure interest.

I love it.

And I blame Paul for it!