Accept No Substitutes

I am sometimes told by this owner of a bevel-up plane or that owner of a bevel-downer, the york-pitch advocate and the scraper plane expert that this or that plane takes care of this and that grain, wood type and so it goes. There are moderate differences between planes but the range of plane type is quite large and only the rich will have access to all of them. That being so, there is no other tool for solving the vast mix of grain and wood types that we encounter in the day-to-day of woodworking that’s better than the ultimate negotiator, #80 Cabinet Scraper.

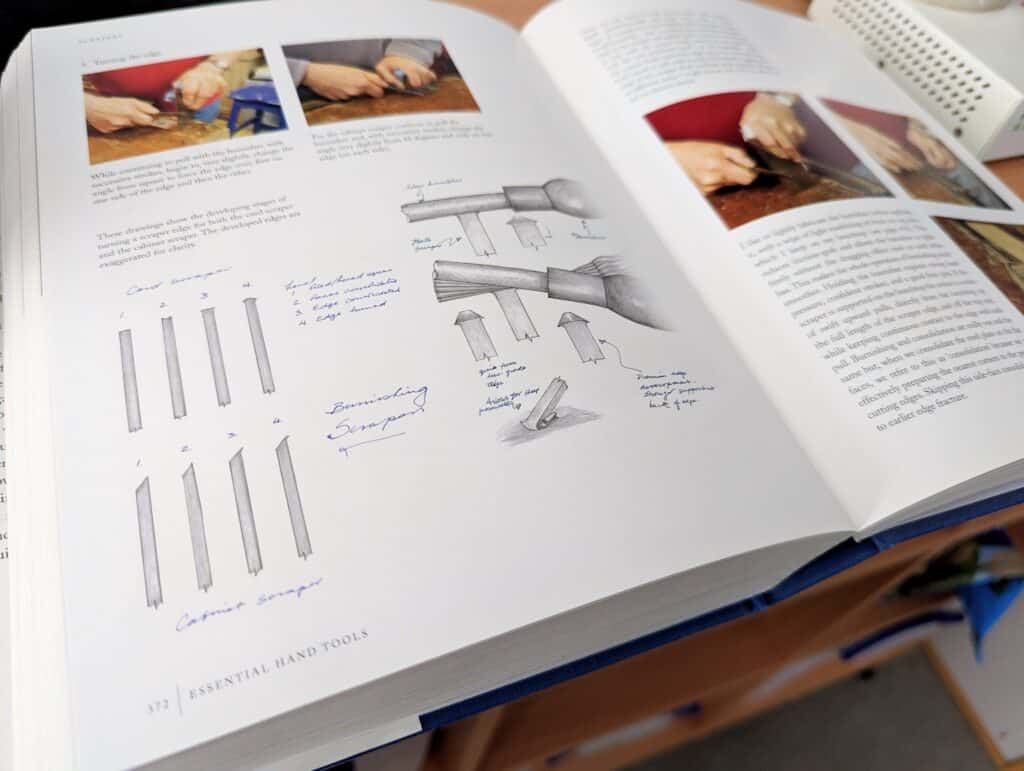

The fact is, a #4 and a cabinet scraper will resolve every and all issues in all grains and all wood types bar none. Hence, our promoting the perpetual use of the #80 Cabinet Scraper and its inclusion in all of my work and my book, Essential Woodworking Hand Tools is the only book that gives over 20 pages dedicated to the setup, sharpening and use of cabinet and card scrapers. For removing heavy swipes or finessing the smallest region and the slightest of depths of wood surfaces, this tool knows no equal. Combining the #80 with the card scraper, a single steel plate, you can readily refine the awkward grains with successes that equal the best of the rest.

This weekend Natalie posted a video on YouTube she and I put together as a new video on sharpening and setting up the #80 Cabinet Scraper. We did it because it was a much-needed explanation to counter so many negative views people had about the tool. What they cited as the results they got from trying one obviated their utter and complete misunderstanding of the tool that should be life-changing when they encounter wild grain, knots and knot surrounds, burrs and burly grain, etc. What was designed as one of the most amazing and unique woodworking tools often ended up being maligned as a useless spokeshave rather than the solution they were truly seeking. Not really knowing what it was more used for nor how it was sharpened, set up and how it was used only served to add to the confusion. We hoped that the video would translate into a few hundred thousand woodworkers getting the light-bulb moment of revelation. If you too are one of them then let us know how you get on after watching the video.

Here are some pages photographed from my book surrounding the scraper family I feel well worthy of merit. I am trying more and more to encourage everyone to own my book because much of the information is what was handed down from man to boy in their apprenticeships. Those days are now well gone.

The only place you can order my book is from Rokesmith Ltd and we distribute and ship worldwide. Here is the link

Really love the book. Haven’t had the opportunity to use my #80 a lot, but did get it setup and tried it out. Worked fine! Thanks for everything you do.

A good 80 or 81 variation is also the answer to how to hand tool work epoxy / epoxy inlays as well … does the trick reallllll nice.

I got a cheap (it had a defect apparently) Quangsheng 112 scraper plane, bought on a whim a long time ago and use it instead of a cabinet scraper. It’s too heavy, like most modern planes, but it works very well. I have to admit, I do like the normal hand plane grip it gives. Obviously, I wouldn’t recommend folks go out and buy a Quangsheng version, but is there any reason that a cabinet scraper #80 is preferred over a scraper plane #112? Or is it just availability? I’m not looking for a reason to buy another tool of course, I have something that works for me, but just curious.

Thanks,

Rico

I have a #80 that I use regularly when I have largish, flat surfaces with areas of challenging grain. I like the form factor of the #80. I find that I often pivot the angle of attach a bit or swing to over to the side or even flip around 180 degrees and come from the other side. With the #80 I find I don’t blow our grain when coming from a bad direction, but often one angle or another seems to be ideal for this know or that area of awkward grain. The #80 likes to pivot like this with the longer wing handles. The form factor also makes me feel like I’m working across the the stock will less of downward or “into the stock” feel you get with a normal plan. Sure, a well tuned no 4 or 5 plane can also give the feeling of skimming across the surface, but a bit of awkward grain combined with the more downward orientation of your body weight can really grab you. I’ll confess, though, that I don’t have a #112 or anything similar so can’t speak to how those sort of planes actually feel in use.

Thanks for this video. You’ve cleared up two mysteries for me. I have a cheap #80 but so far it’s only been useful for taking old varnish off some of the recycled timber I mostly use, because I didn’t have the edge turned correctly.

Plus I didn’t know that softwoods didn’t like the scraper (or maybe the other way round). I simply can’t afford to buy the expensive hardwoods I would like to use so unless I can find old stock to reuse I’m mostly restricted to pine and CLS.

Having watched the video I went straight to the shed and sorted out the blade. Lo and behold it worked beautifully on an ancient lump of English Oak that I’ve been saving in case I think of use for it.

Many thanks.

Yes, I discovered the softwood problem when I used my sharpened #80 to remove some planing marks from some pine. It just seemed to scuff up the surface, whereas on a length of sapele it smoothed areas of difficult grain beautifully. It’s a constant learning curve, and I thank Paul for his straightforward, no nonsense approach to woodworking. My wife bought me Paul’s book for an anniversary and I love it.

I’ve found my #80 sometimes works okay or even well with soft woods, but other times it doesn’t. I find that soft woods vary quite a bit depending on the specific species, moisture content and whatnot.

After watching Paul’s great workbench height video, I reassessed the bench I built some 48 years ago. Yep, it’s too high now and I’ve been uncomfortable using it for the last 15 years or so. I decided to build a new one. The first one was built with 16 2×4’s on edge and planed on a 24″ planer. This one is 18″ wide built with 2 sets of 6 2×4’s, planed on a 12″ planer and glued together. I rediscovered just how badly softwood scrapes. I finally gave up and bought a 4×24 belt sander, which I may never use again. (unless I build another workbench … highly unlikely).

I rarely if ever buy straight grained wood. I almost exclusively select the curliest, wildest grain material I can find. I have to agree fully with Paul. While I am lucky to have a shop with a full selection of bevel up, down, and York planes setup and sharpened, when the grain twists and turns and dives every other direction, the only tools that work reliably are the cabinet and card scrapers (and sand paper). I would say that my thumb muscles are now some of the most used in recent years as well…

My cabinet scraper is always within reach when I am working, instead of a #4 plane I rely on the Emmerich Primus style Jack plane, but it is the same sort of idea. Those two pieces I can do 90% of what I want to do.

I have other planes, too many of them really, but the Primus Jack and Cabinet scraper get the most use.

I have used the 80s spokeshave several times when restoring. This allows you to perfectly remove old paint from the veneer without damaging the surface. However, therefor I use the upper edge of the blade, which is simply ground at a right angle, not the “hooked edge”. This procedure is particularly suitable for nitrocellulose paint because these are really difficult to remove. In the end you don’t have the usual mess, but simply vacuum the powdered paint from a perfect veneer surface. I’m very glad I stumbled across this planer a few years ago.

I was introduced to the #80 on the 1980s by my grandfather. Before a career in the navy, he had various jobs, and one, must have been in the 30s, was at a furniture factory. All employees were required to have a #80, and his job was to pull tabletop glue-ups and scrape the glue lines. He gave one to me and one to my father. We were completely ignorant of such, and were sure that this was some kind of weird spokeshave. He demonstrated the basics (nothing like your excellent instructions, BTW) and insisted that an old engine valve (really too soft) was ideal for burnishing. I have grown to love the tool ever since. Have picked up a couple spares when I see them at the flea market. Just awesome. And of course I’m a better user thanks to Paul Sellers.

Paul’s book + DVD is a must-have for anyone who is serious about hand tool woodworking. There are not many options: enter your own apprenticeship, then embark on a hand-tool woodworking career, or learn from someone who already did that, and generously shares his knowledge and experience. I have learned more from this book than any other sources. My first education about hand tools came from Roy Underhill (I watched mainly to bet on how long until he cut himself in every episode) and Richard Maguire. Each one teaches from their own experiences as woodworkers. Paul is the most thorough and the most practical.

I bought a new Stanley #80 (Chinese) some years ago. With a little bit of smoothing the sole and simply following the instructions that came with it I found it a very useful tool. Nothing else like it for cleaning up difficult grain.

I do not understand why it gets such a bad press.

I was lucky to find and buy a boxed, new Stanley 80 cabinet scraper on Amazon a few years back, I think it was sold by Stanley UK :), or what left of them. It was very reasonably priced at the time too; no doubt influenced by PS, I had been looking for a reasonable second-hand #80 scraper on eBay, carboot sales and a local vintage tool seller, without luck. The new one was no more and sometimes less than second-hand ones on eBay at the time. It was a happy and easy decision to buy new in this case :). Alas it was only sold on Amazon for a relatively small window of time though.

I was alarmed at first by how short the card/blade was – I seem to recall seeing much longer ones (perhaps homemade?) in several photosgraphs. I should not have worried it is long enough for my foreseeable needs :). Following Stanley’s fairly basic instruction- sheet, I got it sharpened and working very well in a short time. No doubt Paul Seller’s influence on me helped considerably 🙂

Yes, I also think the Stanley #80 scraper is a delightful tool. Enjoyable to use 🙂 And it is always good to reduce or eliminate the use of sanding papers 🙂

Have had a card scraper for about 30 years my dad told me about them and gave me a brief idea on how to use them. A few months ago i was having trouble with some Beach trims i was making for a kitchen renovation . At this point i bought a No 80 what a fantastic piece of kit once the card had been ground and burnished as per instructions supplied by yourself . A game changer no more hours of trying to sand out marks in timber . now more ripples of a power planer and a time saver to much quicker than a power tool and the added bonus of piece and quiet. It sits next to my No4 with the tow of them providing all i need for most jobs Thanks Paul just a shame the internet was not about 40 years ago . As you say at that time power tools had become common place and the people who knew hand wood working methods just sat in the corner puffed on there pipes and thought that those days of the hand tool craftsman had gone forever . Thank god i spent the time to learn the skills that i can now look into a piece of wood see its potental and bring it to life as something usefull in the real world . Well remember a friend who wanted a pair of wooden doors for his workshop restoring old cars . Told hm what timber i needed set about hand cutting mortices and tenons . That was 30 year ago they are still there long after the doors that were machine made on the unit next door have fallen apart and rotted .

So if the No. 80 and the card scraper are problematic on soft woods – as is the consensus opinion – how does Mr. Sellers deal with tear out in these woods encountered during smooth planing? I know he is not fond of using sandpaper to repair issues like this. But is there an alternative?

Stephen, Thank you for giving me this question. Your saying, “I know he is not fond of using sandpaper to repair issues like this.” is more likely to give others the wrong impression so this will give me a good opportunity to help others understand the real issues and my position on them. I hope that that’s okay. Firstly, on the issue of scraping soft woods (as distinct from softwoods): You can use scrapers on some if not most soft-grained woods whether hardwoods or softwoods. That said, they always work on hard or dense-grained woods and are perhaps less predictable on the soft ones. If you do want or need to scrape softer woods, you must be prepared to sharpen and resharpen far beyond regularly and even when you don’t detect any dullness in the cutting edge. What am I saying? I’m saying even soft woods like pines, firs, spruce and such will allow a sharp scraper to refine their fibres. But you must be diligent to keep the cutting edges refined. Looking at the consensus does not read Paul Sellers in there really. I might offer that 99% of woodworkers have no concept of card or #80 scrapers let alone how to sharpen them or use them. I will indeed resharpen and scrape difficult areas in soft woods. But I mastered the art of switching my plane in different stroke directions as I work awkward areas and am used to refining even difficult grains using my smoothing plane in short, multidirectional swipes with lift-offs on short sections with the very finest of settings. Another technique I have videod on is stuffing shavings into the throat of the plane with the left hand while swiping using the plane with the right. I have saved many a troubling spot using this technique which was passed down to me as a boy in my apprenticeship by the men I worked with. As to my not being fond of using sandpaper: I use sandpaper on all of my projects but not as others do automatically to take out poor hand work or planing and scraping and machine marks. That said, it might well be the only answer for some woodworkers unused to hand tool work or, as does happen, where the complexity of grain structure is such that you can eliminate a lot of really hard work. My countering this over the years has been purely to equip people, woodworkers, to master the art of planing rather than automatically reaching for a belt sander and random orbit sander which is what was happening in the lives of most every woodworker I ever met. I think my using hand planes eliminates about 98%+ of reliance on sanding to achieve what is a better finish using planes. So why do [people rly on power sanders? Well, it’s because boards passed through a power planer were left with the telltale power-planer stripes going across the grain that would be highlighted when paint of varnish was applied. If you are a machinist woodworker, you have absolutely no choice but to invest in a helical cutter head for power planing with or to belt sand and then random-orbit sand to take out any power-planer and sanding marks. This, of course, assumes that all woodworkers have access to such equipment when half of the more global audience I reach out to does not. For such soft woods I rely more on a card scraper than the #80. Sharpening scrapers demands our patience because it is such an elongated process compared to plane sharpening. i do understand the reliance on power sanding and I am not at all reluctant to use such methods. `what I faced was the unbelief that people had in themselves that they could actually master the use of hand planes. Hence what you see in my videos is the realness of real woodworking and not just some guru standing in front of a camera after spending half an hour sharpening and setting a plane so he or she can take a few onion skin-shaving off of a strip of pristinely prepared wood –– totally unreal. The videos we make (now thousands of them) of me planing and scraping awkward grains I naturally encounter in my day-to-day of making projects, knots and surrounding grain too, are in the processes of building the projects we train people worldwide through. We insist on realness not staged shots.

Mr. Sellers:

Many thanks for your thorough analysis of my question. To clarify: I never had any sense that sandpaper has no place or purpose in your shop – but rather, that you believe that too many people use it too often as a first resort when there are better options. I fully agree, and in this case my eyes have now been opened to one of them. Your advice to scrupulously re-sharpen an edge which to my relatively untutored eye still looks and feels sharp is something that I would never have considered on my own. I had attributed my own difficulties with scraping soft wood to either the immutable laws of physics or some flaw in my technique that I could neither recognize nor overcome.

Kind regards,

Steve

When planing pine and other soft woods, I found especially helpful these two tips from Mr. Sellers:

(1) increase the distance between the leading edge of the plane iron and the leading edge of the cap iron;

(2) firmly hold a wad of shavings in the plane throat when passing over an area where the grain changes direction.

Regarding (1):

— soft wood shavings seem more prone than hard wood shavings to lodge under the cap iron

— moving the cap iron back seems to help soft wood shavings to curl clear of the cap iron

Regarding (2): the wad of shavings seems to apply counterpressure that resists the iron’s tendency to create a deep tear when the grain abruptly changes from rising to diving.

Both tips have helped, but (1) was a significant game changer.

Thank you!

Paul,

I saw your video of how to set up and use a Stanley #80 scraper and I have to say thank you as the vintage one I bought over ten years ago remained unused as it came with no instructions. I bought a replacement iron from Lie-Nielsen as the scraper I bought had no iron. Being the iron is sharpened on both ends I have to be careful reaching for my other hand planes as I store them all together.

C’est si bon,

Paul, your book is one of my most treasured tools. From the early days of my hand-tool woodworking, yours was the only voice I trusted definitively when I’d search for the “missing pieces” to my puzzles. When my wife gave me a copy of your book for a birthday years ago, I read through it in its entirety, and continued to go back and reference subjects as a matter of course in my EVERY DAY shop time. So thank you for giving us so much value for so little money, and for pouring all of yourself into your book and the hundreds or thousands of hours of video you’ve put into the ether for anyone who may gain from it. Your legacy is astounding.

As for the #80 and the card scraper, I spent many hours over the course of several years trying to master the sharpening and use of these tools. Every so often I would have a small victory, only to be denied reproducing those results once the tool was dulled. Then, a couple years ago, I GOT IT!! A bright light finally shown on a previously dark and unexplored area of woodworking for me. My confidence in milling lumber and finishing projects by hand went way up! It took effort and time, but I’m glad it didn’t come cheaply. Like all of the woodworking hand-skills I have learned. I EARNED them and now they are with me for life and I will be able to pass these down to my boy in a few more years.