Another Tip You’ll Like Too

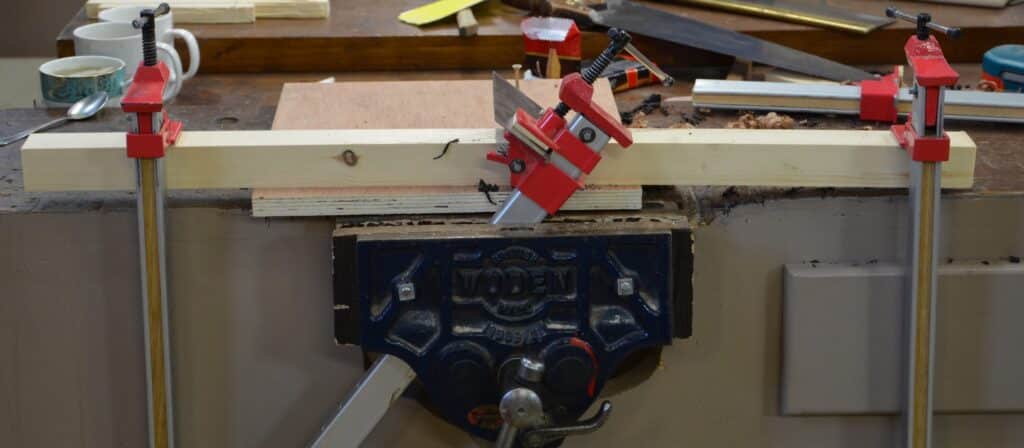

Here’s another one you haven’t seen either. In an emergency, for thicknessing just one thin stick, I set this up in a Black and Decker Workmate years ago and it worked. I thought you’d like it. And the great advantage is that it’s almost an instant setup. Additionally, it offers an infinately adjustable angle-of-presentation so no angle finding, no sliding bevels and protractors needed. Just adjust according to ‘feeling’ for the cutting edge when you pull your wood through. Depth adjustment in this case comes from adjusting the clamp in the vise.

There is not much to tell you beyond what you see in the pictures so I will just park it here and leave you to it.

Use whatever support platform you have to hand. The plywood platten worked because the bench top was ragged. The two-by-two was just a simple way to clamp a support bed to the benchtop. What you cannot see is a layer of silicone shelf liner between either one of the clamp heads and the card scraper to stop slippage and it does not slip with this in place.

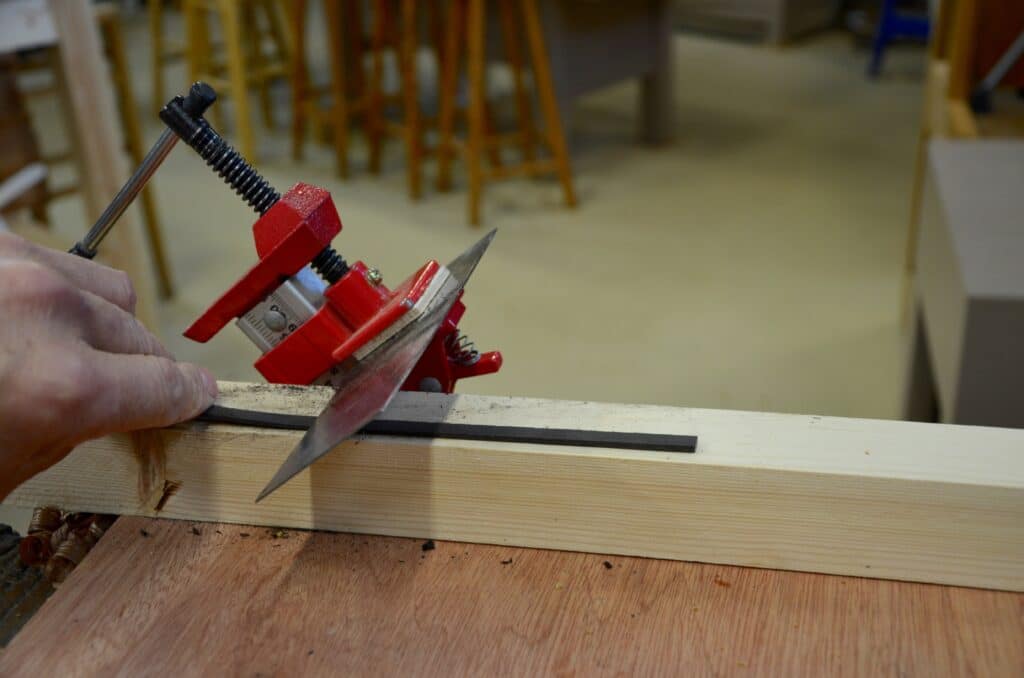

Move tighter up nearer to the side of the clamp where there will be no flex for the final thickness. Just keep passing your stock through the flexible side until it stops removing shavings and then move in to the other side. You can also press the card scraper to take off heavier shavings.

Additionally, as an afterthought really, you can move your scraper across from side to side as you lose the premium cutting edge. With the four cutting corners and working on 12mm wide or less stock that’s a lot of ‘planing’––many a hundred metres at least!

Empirically magnificent !

Beautifully empirical (lost in translation)

Just a newbee question because i’m not familiar with use of scrappers : Do you push or pull the piece you want thinessing in this set-up ? Sliding the piece from left to right or from right to left (considering the last picture) ?

Thank you for all the good advice you give to us here.

Regards from France

In this picture, I am pulling the wood through from right to left as you look at the picture. That said, if the wood is thicker and therefor stiffer you can push or indeed push with one and and pull with the other at the same time. Thin wood needs to be pulled through so taking this picture, and say the wood was a millimetre thick, you would be pulling from right to left.

Thank you for the explain Paul 🙂

The best problem solvers I’ve seen are woodworkers. I’m sure tool and die makers are in that group as well. These little problems can derail a project pretty quickly if you don’t come up with something. Thank for another example.

This is so ingenious, Paul! It’s also a perfect example of the joy and satisfaction of making by hand with not an iota of danger to one’s digits.

Now what I am missing is:

– how to make neat grooves to insert those strips therein;

Making the strips with a defined width doesn’t seems too difficult.

Would you first bring the strips to the desired width or first thickness them?

Very classy man. Thank you.

Jim monette

You know, it is just so nice to see go to mail and see another contact from your group. I am thankful for all the things that I have learned.

Lovely.

I recently made a dovetailed box according to the design in your recent youtube video and blog posts. I used some Ash that had a gradient from light to dark across the width of the grain and took care to line this up around the four sides.

It is the most beautiful thing I’ve made so far, and it came out so well that the other half has asked me to make a few more as gifts.

This will come in handy for thicknessing the retainer strips quickly and accurately.

Thanks Paul.

Ingenious! What would we do without clamps???

In my local antique / house clearance centre, clamps sell really quickly even though they are not a lot cheaper than new.

Very timely! I am working on a bench and want to inset a thin accent strip on each end. This is exactly what I need!!

Thanks!!!

The scraper idea is similar to what French violin makers used when adjusting the side ribs . It had a fancy French name too .Can`t recall the word now .

That’s because it would be in French and not English, I suppose. Artisan = skilled craftsman or woman and atelier = studio or workshop. Artisan is used more commonly now but in other countries and the UK whereas it was never used in 1950 through 1970s in the UK. Atelier is never used outside of French speakning countries or nations such as parts of Canada and others I suppose.