Debunked the mysteries

There can be no doubt over the years I have debunked many myths and mysteries surrounding woodworking over the years,mostly to make my world of real woodworking inclusive of everyone and available to anyone. No you don’t need heavy planes, retrofitted plane irons and definitely not thick and excessively hardened plane irons with particularly special steels and cap irons (chip breakers USA for some reason). Saws, chisels and other hand tools have all become more widely understood now and even the very best knife for cutting my knifewall has been distilled down to a very simple and functional Stanley that IS resharpenable costing under £8 and $8 respectively.

A direct result of my work debunking is that thousands if not hundreds of thousands of lost and forsaken Stanley #4’s have resurfaced and found real value in the hands of woodworkers around the globe. When I first blogged on the superb refinements and simple benefits of the very basic and standard Stanley and Record #4 models in defence of Leonard Bailey’s brilliance and to give a well deserved and more global recognition of his establishing the plane of the working man, I was buying the plane on eBay for between £1-4 and paying £3 shipping. Today they sell from anywhere between £15 and £45 and still they are worth every penny and match the very best of the best for many practical reasons. I know we all want a bargain and we don’t mind investing a little sweat equity (elbow grease) into the de-rusting and restoration program, in fact most of us actually want that task ourselves and are disappointed when someone’s done it for us, but paying even much more than £45 for a well used but not abused Stanley is not paying too much. You cannot wear them out. I am still using my Stanley #4 and #4 1/2 after 50 years of daily use full-time six days a week. Yes, I am on my 3rd and 4th plane irons through sharpening (and that’s never grinding them but hand stones only) alone, but no retrofits for thicker or harder irons. I doubt that there are many woodworkers alive that have used a hand plane as much or as long as I have and I can attest to their real value. The only criteria you need to watch for is to buy models from the pre 1970’s and try not to buy the more recent plastic handled models that split. Even so, I have purchased newer models and refitted wooden handles, worked on the poorer finish in the engineered components and ended up with a good plane.

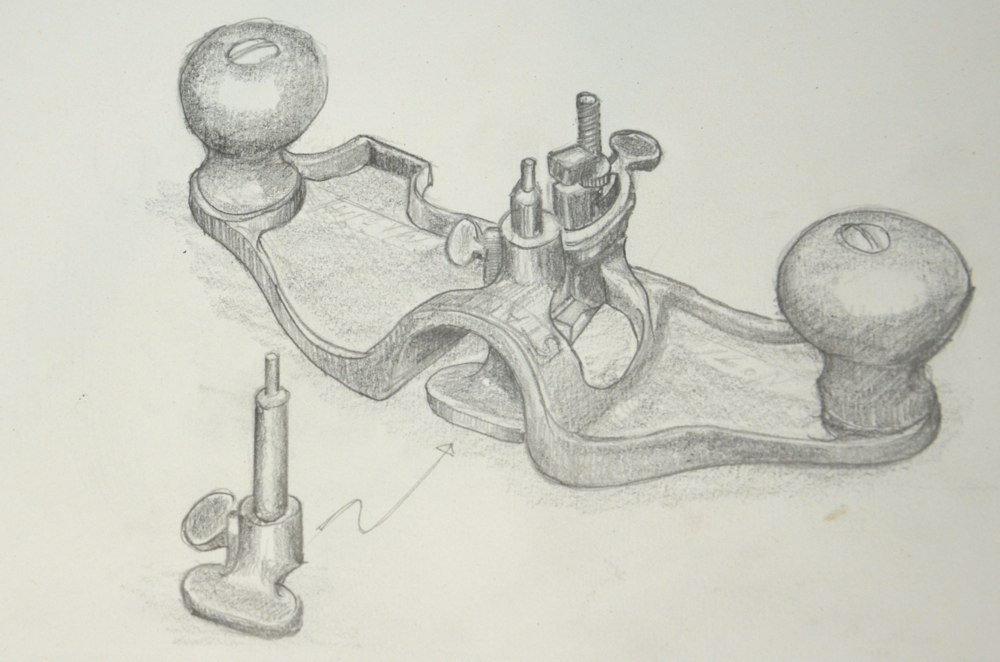

In other areas of woodworking hand tools I have done the same. Cabinet scrapers and saws, are now very much back on the scene and the once much ignored router plane has soared in price reaching in some cases over £100 when in good condition and with all of three cutters. Why is that? Well modern makers made their own versions but removed some of the improved features developed and deemed necessary by Stanley and available with the Stanley and Record models that still had great value to the tool and added versatility too. Now their routers are good tools. Don’t get me wrong, and I am glad they are around, but what looks the same is not necessarily the same. Again, even though it was well over a hundred years ago in some planes, Stanley designers like Leonard Bailey went to great lengths to meet the needs of the users. They tested out their products and added features to reconcile any and all issues brought to them as concerns by the craftsmen using them. So what are these differences. Well, consider the old model wooden counterparts that did indeed remove the fore part of the sole to create an open aspect in front of the cutting iron first. Now hold that though and you will see that the originals were the precursor to the bettered Stanley #71 and Record 071 models. Much of it surrounds the fact that Stanley and the Record knockoffs of Stanley (most of the Record tools were copies of Stanley models) had features surrounding the hump at the front.

The modern versions of the router plane are minus many features offered by the Stanleys and Records. They offer no closure to span the gap and no internal post for controlling depth of cut and guiding from within the recesses of say inlay work and such. So to achieve close parity with the Stanley and Record models they offer two planes—the continuous sole without the hump and the hump-backed model but without the Stanley refinements. But even with these two planes, finely crafted as they are, you still don’t get as much as you get with one of the Stanley #71 or the Record #071 models. Look for a post that receives the cutter on the reverse of the post support because this puts the cutter on the outside of the sole and so the shavings don’t get trapped. The Preston router did this as well as both Stanley and Record and so to

So we see once more that things may often appear the same but never quite give full parity with the originals of Stanley. Stanley invested their best designers to become the best tool makers for the worker and were prepared to invest in the details. Now this is recorded here from a craftsman’s perspective. No one has written these things you see. So now you see why you should really consider that possibly paying even £150 for a full set of the older models is worth the money. It’s yet another lifetime tool that’s critical to your kit. Now watch the Bay prices rise again. Perhaps then one or two modern makers will rise to the challenge and give us what Stanley perfected about a 100 years ago.

Fantastic post. I hope someone at Veritas or Lie-Nielsen sees this. But then again their designs are probably set in stone and are unlikely to change.

Well, the only little thing I’d like to say is that a very few years ago I bought my Mora laminated carving knives (eminently sharpenable) for about $15 each. Mora is catering to North American mass market tastes a bit more now, but they still are making high carbon, long-lived, easily and keenly sharpened, laminated carving knives. I’ve also been caring for a non-stainless 1095 steel knife since I was a Boy Scout.

I did pick up a Stanley #10-049 on your word, and it very well may be a #4, renumbered on this side of the pond. I can leave it on the bench, lock it open or closed, sharpen and/or replace the blade, and safely drop it into a pocket. The Mora rides in a sheath and Philadelphia police would frown. I have rehabbed my grandfather’s Stanley #3, without replacing the blade.

Besides, I couldn’t bear to have my ultra sharp carving knives knocking around a bench, even if the plane is just the right size.

But, Paul, what am I going to break those chips with, my teeth? They aren’t your kind of fried potato-based chips, you know.

I have two of the Stanley #71’s and love them. I bought one and someone gave me the other. The one I bought is missing the shoe but I can use the post as a depth stop. I have found that on dadoes using an electric router I have had to use my #71 to make the depth consistent.

One nice thing about Veritas is that they make cutters, and a post, that will fit the Stanley. I ordered some and really like the added versitility.

Thanks for the great post. And yes when you, and others, extol the virtues of a particular hand tool the online price skyrockets.

Oh, sorry, I was off-topic a bit. I picked up a nearly unused ECE router, complete kit, for a fraction of the list price from a dealer who had no idea what it was. The front is closed. The shavings just fly up out of the massive top ejection port.

In the last month I’ve been lucky enough to buy a Record 071 and Stanley 71 1/2 routers on TradeMe (New Zealand’s version of Ebay). The Record 071 has all the guides and depth stop with the 1/2 and 1/4 inch cutters, but missing the pointed cutter and cost just under $90 NZ with postage. The Stanley 71 1/2 only has the 1/2″ cutter and is missing the threaded adjustment post & wheel. I will have to get my engineering skills going to fix that, and this cost about $70.

Just last week while looking around a local secondhand shop I spotted a Stanley 271 router. The cashier had no idea what it was or price so inquired with the manager. I walked out with a 5 dollar bargain. I’ve yet to clean and restore these, but I’m sure once they are clean and sharp they will all be worthwhile additions to my hand woodworking tool kit.

Pete

I know that when I was in Junior High School, we had wood shop (then metal working, electrical stuff, and drafting) They don’t have that any more except in special schools. Your cashier and my dealer, and a lot of others are paying for that loss of manual skills education.

I have the Millers Falls No 67, which is in every way a Stanley 71. Even takes the same cutters.. I’m sure the threads are different, but just about everything else is interchangeable.

At $35 complete (missing two cutters, but all other parts are there) at an antique show it was a bargain three years ago. Now I’m glad I jumped on it, because they’re up around double that today!

I disagree, I truly lament this price inflation on old tools and I am in fact very bitter about it. I’ve refused to buy several dozens of planes I could have because I refuse to participate and add to this price inflation whackyness.

Frankly I don’t have a lot of money and it seems to me like a bunch of rich urban hipsters are buying up all the tools because it’s fashionable at the moment and driving up prices. It’s like when all the rich people started shopping in 2nd hand stores and flea markets and drove up prices to the detriment of the actual poor families who need to go there to find goods they can afford.

Here’s hoping they’ll end up with a bunch of tools worth only a tenth of what they paid once the fad passes and they get bored of the whole idea.

Not sure at all if that’s what’s happening here Dennis. I think that for sure the feedback I get from students, visitors, emails and comments is that since the support providing the right information people feel confident the tools work well after a little effort. They see what I do with a plane or the planes that are common and trust what I am saying because of the visual impact it makes.The prices are not hiked. People’s confidence and demand naturally has raised the price. People tell me they have had great success.

Very bitter. I think you’re going to have a long wait.

I have acquired a #3½, #4 and a #7 for little money and I just found a #78 for a reasonable price as well. So I am not entirely without tools.

The way the world’s going, bitterness is going to be a running theme in society anyway.

” no internal post for … guiding from within the recesses of say inlay work” I’m having a hard time picturing this. Do you take the foot off the post, establish the vertical walls of the inlay with gouges, and then run the post along those walls to flatten the inlay near the walls? How was the bulk taken out?

The Lee Valley router can be run with the cutter on the other side of the post so that shavings won’t be trapped under the base. Does that solve the issue with doing stopped housings?

re the Veritas, yes, I was saying that. Re the internal guide, yes, remove the foot, rough down and establish any walls to a knife wall for instance, then you can rub the post along or against the knifewall and this aligns the edge of the blade to wall. I think the modern makers could have created a different addition for this purpose as a guide but decided we crafting artisans didn’t need it because they are not woodworkers but salespeople mostly.

Dennis, you’ve actually done well acquiring planes you want. You may have to wait for other things. Some things never come your way. I used to collect cameras; they sit in a cabinet behind me. The film cameras are worth little to nothing on the market today. That won’t subtract a thing from the pleasure I got from hunting for a price I could afford (a 100-year-old Kodak that works today cost me about $10), refurbishing them (itty, bitty springs and screws) and finally making a photograph. I finally offered $100 for a lens I used in 1970 (worth thousands to the US government), and just got skunked by a fellow who bought it for $120.

I was done a favor — how much time would I spend fondling the lens when I have my grandfather’s saw set pliers to clean and learn how to use. Cost? US$ 0.00.

There’s something to be said for your comment that bitterness will be a running theme. It’s the “anyway” that gives me pause. The society that will be bitter starts each day at your front door. Your choice.

I found the Millers Falls version much better than Stanley and Record. Tried them all.

Well at the end of the day you might think I’m one of those hipster urbanites being a designer working in a city with a 1 bed apartment. But I love restoring a life time tool and aquiring the skills to use it effectively. I’ve been at it for a good few years now and can safely say I’m passionate about it. Being bitter about tools being more valued in our modern society won’t bring you peace.

I’m not sure who you’re referring to here, Mike, or answering. Urbanite hipster I guess means an affluent consumerist city dweller with an ever-optimistic outlook? I feel at peace much of the time and condemn no one for their choices but offer additional choices for people to pursue as best they can so that they no longer have to pursue expensive and unnecessary methods of woodworking if they can’t afford posh tools or host a massive footprint for machinery when the methods don’t fit the need nor the pocket the price.

Paul, there was a prior posting in the last couple days, I think in this thread, by a person who described himself as “bitter” about the inflation of used tools prices. He attributed this to urban hipsters who bid stuff up. You then answered that quite well.

I think it was someone was was probably disappointed at ever-higher prices, as I myself have been occasionally. By, then I’m probably much older and inflation is part of life in a global market. (although the global sort of tempers it a bit, IMHO.)

I am urban, but the hipster part is all worn out.

Ah! Got it, yes, I think it was Dennis who described things that way. I still enjoy the search for the best buy. This week I bought a quite lovely panel raising plane I had wanted for some time. They are hard to come by and I am thinking of making one in woodworkingmasterclasses as they are so functional and so handy too.

Since I’m now a proud paying member, and I’m gearing up to make some simple grooving planes, that’s good to hear. Chiao!

I too have been searching for a raising plane both small and large versions, I’ve never made a plane as much as I wish I could but it just seems so difficult. I look forward in watching you make one if you make a video on it.

Haha liked the worn out bit! I’ve started at a local men’s shed and it’s fantastic being round a great bunch of old boys. Love the banter and hopefully we can do some joinery by hand. They’re doing wood turning and Celtic carving at the moment.