More on the mortise – the peripherals?

Actually, they are not so peripheral

It should now be obvious that in my view mass is less important when chopping mortises, especially for the cabinet maker and lighter weight joinery most woodworkers find themselves employed in. When you see the next video series on making the workbench on Youtube you will see how effective a 1/2″ bevel edged chisel is on chopping through 3 1/2″ legs; knots and all.

A convex camber eliminates unnecessary secondary bevels

On chopping the mortises in the video we posted a couple of days ago, looking through the glass, you could see clearly that there is considerably more resistance to the huge surface of the bevel of the chisel. Leverage points, the fulcrum of the bevel, is a long way from where you need it and so by the time leverage is exerted, it has only minimal effect and when leverage is applied it tends to push the whole chisel from the hole and not lever our the waste.

Newton’s laws

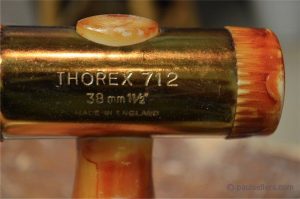

One of my favourite chisel hammers

Back to Newton’s law:

For every action, there is an equal and opposite reaction

Literally it means that in every interaction, there is a pair of forces acting on the two interacting objects. The size of the forces on the first object equals the size of the force on the second object. The direction of the force on the first object is opposite to the direction of the force on the second object. It takes much more weight to drive the heavy weights and this is what makes the difference. Add to that the massive bevel in the wood being over 1′ instead of less than 3/8″ and you better see the criteria.

All of that said, I believe there is a place in woodworking for the larger heavy-weight chisels, otherwise those men of old would not have developed them to such a level of perfection that they did.They are quite beautiful. I do enjoy my heavy weights and have a set made by Ray Iles that are second to none in craftsmanship and quality. Old mortise chisels are hard to find but Tools for Working Wood carries the very best new-mades from Ray Iles and is the sole distributor in the US. I used to meet Ashley Iles, Ray Iles’ dad at tool auctions and such back in the 70’s and 80’s. When it comes to the art and craft of tool making, the Isles family have it down.

With regards to secondary bevels.

Manufacturers bevel at 30-degrees

A convex camber works well on all chisels and eliminates the need for secondary bevels but gives the same keen edge in short order.

Obviously, on my mortise chisels I keep the start of my macro-camber at 35 degrees (see top pic) and then drop off to around 20-degrees on the close of my sharpening and honing strokes by the natural process of honing. I never grind the bevels of my chisels on a mechanical grinder except to remove damage by edge fracture, hitting something foreign in the wood or dropping on concrete.

Thanks Paul, I’m looking forward to the next workbench video. So much free info has to be good. Great job buddy

This is interesting about the 35 degrees for mortises, thanks for the info!

I was noticing as I was chopping down a 12mm dado that my 30 degree edge was getting bent and fractured a bit too fast —the edge might have been less than 30 degrees I’m still figuring out freehand sharpening— so I tried keeping the chisel barely more upright while sharpening and that helped keeping the edge neat longer,