Buying Good Tools Cheap – The Router Plane

For more information on the router plane, see our beginner site Common Woodworking.

Routers online

Routers for most people conjure up a range of different images ranging from face shields and dust extractors to dust masks ear plugs hearing protection and other head gear resembling and American football team player or a SWAT team member. Of course for 99.9% of machinist woodworkers this is essential equipment. That equates to most woodworkers and as we know, they are not so much working wood but working machines.

From my culture these images are not so much a part of my psyche. I wish that were so for more people too.Mention router and I automatically think of a Stanley #71 or Record #071. This plane type has been very much a part of my working tool arsenal for decades, and, although I like these makers quite well, Veritas routers are indeed the best modern-day maker of router planes.

The main difference between the two planes is the nickel plating of the Stanley and the painted casting of the Record in the Record blue colour. Both seem to last about the same with regards to rust prevention and if they are used well, which all of mine are, they don’t rust that much at all.

Both of these models were made in England as can be seen.

My totally favourite router plane is one once made by Edward Preston. I love the long rectangular base and would that the Veritas, Stanley and Record router planes had the same sized and shaped base. Actually, I bought two router planes this past week; one was indeed a Preston and the other a Tyzack. These don’t come up too often on eBay, but my recent find left me buying the very rare Tyzak for £19 and the Preston for a buy-it-now of £55. The two planes, though made by different makers, are almost exact mirrors of one another in shape and size and most likely came from the same casting foundry one way or the other. This often happened in Sheffield in times past. Both routers are excellent. Unfortunately it’s unlikely you will find one again. I see one every few months but this is on a diminishing level. The attention to detail is what drew me to these planes, so let’s take a closer look.

Why this router is so good?

The main aspect I like about both the Tyzack and the Preston router is the larger platen that distributes over a wider surface area of the wood being worked. I also like the openness in the frame casting which allows for full vision of the wood I am working. The extra length gives me the ability to work tenon cheeks more accurately and with the extra leverage this sometimes needs, I find it takes less effort.

I also like low profile knobs on routers, a criticism I have of all other routers. The lower the profile the nearer the centre of thrust approximates the centre of the cutting edge and the less over-leverage I get that can cause the router to trip as most of them do from time to time. I also like the minute detail in the knob parts being brass and with the undulated rim that gives dead-on alignment and sure fixing.

#71 and #071 models

The collars and mechanisms of both Tyzack and Preston are the same as the Record and Stanley as you can see here and top two pictures.

Both Stanley and Record produced the #71 models with only slight variations on the the theme. Traditionally, Record added the ‘0’ prefix to their numbering system on planes following the Stanley styling. These tools have proven steadfast and substantive for a century and more and aside from the cutters getting too short to sharpen after decades of use, these tools last, work and work well.

They come up often enough on eBay and generally have all of the original cutters in unused condition. These past weeks I bought about ten of them to see how much on average they would sell for. My average price was £25. I think that that’s excellent value for money so wait a week or two until the bidding drops to normal again and buy yourself a bargain as they occur. No one should be without one of these tools.

Old woman’s tooth

These planes work fine too. I used one that I made for years and then left it in storage and haven’t gone back as yet. I did a blog post here on a poor man’s router also, made from an Allen key. With the Old Woman’s tooth, also call a Hag’s tooth, we used to use the wooden plough plane irons for the cutting iron. I think that the metal planes work more accurately for my work and of course the reason is that they give me the infinite adjustment I want for micro adjusting depths of housings and so on that I get with the threaded depth adjustment mechanism. Take this away and both wood and metal routers work with equal ability and of course wood on wood always feels best. To cater to this, most all metal planes have screw holes for attaching wooden soles. Wooden soles soften the contact between the tool and the wood and are less likely to damage the work. This is especially important on fine work such as veneered surfaces and inlay or marquetry work.

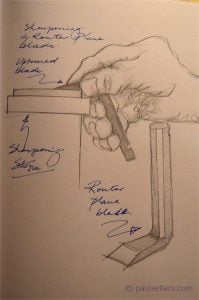

Sharpening router cutters with fixed, single-piece cutting irons

These cutters don’t generally need the same level of sharpness say the smoothing plane iron generally demands, but they sharpen easily on diamond plates and I keep a two-sided EZE lap for this purpose. I rest one corner against the vise and the other end in my belly. I then adjust myself to grip the cutter upside down and rub the cutter back and forth until I have a good angle on the bevel. Once that’s done, I turn the cutter correct way up and hone the underside of the shoe-shaped cutting iron. I start on 250-grit, go to 600 and finish off at 1200. That’s enough for a router plane.

I think in a case like that you could weld a piece of 01 steel onto the existing stem and you have a quick and effective repair.

Hi Paul a quick question, would you buy a Preston 1399p with 3 cutters for £80 or a new veritas for £150ish? Thanks in advance.

I like both router planes but love the Preston because of it’s larger platten and low profile, vertical handles which give greater direct inline thrust where you need it most, at the base. I like the accurate machining standards Veritas has and I also like the fine tuning the adjustment gives me in the Veritas. I suppose for me it may not be a question of ‘either-or’ but more prioritizing which one first.

I plumbed for the Preston, haggled to £70, but, its arrived and it seem thats collar is from a stanley 71 so its not as good a fit as I’d like. Any suggestions how I could improve on it?

Hi Paul

Just started my very first hand tool woodworking project (the Paul Sellers Sharpening Plate Holder) yesterday and had a question on the Stanley 71 Router. The one I picked up at an auction came with the adjustable mechanism located in front of the cutter. The screw that is visible in your photos was stripped and would not tighten to the rod, so I took it off and set it aside. The router worked very well without it and I assume it is not normally used – since the routers in your pics don’t have them either. My question is, what is its purpose?

Thanks in advance,

Two functions for the hole. One is to insert the rod and use the router in narrow housings and grooves, the rod keeping the cutter aligned with the groove being routed out. Two,a sho attached to the rod or separated, allows the router to be used on narrow stock with the infil shoe spanning the narrow edge and prevent the router from ‘dipping’and gouging too deeply.

Hi Paul

I recently bought a Stanley 71(?). It came with 3 different cutters plus one that is v-shaped. It would be great if You guys could do a video on how to sharpen them, especially the v-shape type.

That one give me gray hair.

I would love to see thiss, too. 🙂

I know we just did this for the videos with the new book but beyond that I will have to take a look.

Bought book & dvds! Waiting anxiously for them…! Canada…

Paul

I do some coopering and make wood buckets……I don’t have a croze, but thinking one of these router planes would work well to make the “croze groove” inside the bucket for the bottom….thinking I could extend the cutting iron and then attach a wood piece something like a croze itself to be a “fence” of sorts to guide the iron against the inside of the bucket staves.

Does this sound practical?

It sounds as though it could work. You won’t lose much in trying.

I have record 071 and a stanley 71 1/2 wich I like better. But the first came with a the detachable pointed cutting iron which I destroyed very quick by setting it to deep in softwood. And the other came with a 1/4 inch cutting Iron. Then I needed new irons, where to get them? I bougt a number square shaft srew drivers, nice crome vanadium steel, Bended them with my torch just above the flat part, and after the torching I could file them easily into shape, They stay sharp ,because I took care not to overheat the endpeace by keeping it cool in a metal vise costed me € 1 a peace !

Bravo! Brilliant idea. Will for sur try it! Cheers!

Thank you for your kind explanation. I am enjoying your DVD. As an Asian woodworker, I can compare the difference and similarity well. I found and overwhelmed by the real similarity between the western and Asian woodworking style.

Hello my Asian friend, It was nice to see your comment here and to see and hear of the similarities you speak of. Our English word for joinery is harmos, where we get the word harmony. I think regardless of continent, we woodworkers find our greatest harmony making joints with our hands.

Hi Paul,

First, thanks for the video on chopping mortises with bevel edge chisels. I just found it, tried your technique with a heavy mortise chisel & it made huge difference to how I’ve done it before. Much faster, and better result too.

About routers, you write above that Preston & Stanley blade collars are the same. But isn’t the blade in Preston seated so that a flat face is facing forward, whereas in Stanley it’s in 45 degree angle… so the question is, can you use a Stanley iron + collar in a Preston plane? Or a Veritas iron?

Thank you for your reply, Paul. When I see your youtube video for making square wood by handplane, I thought that lthat’s the same way I learned’. Although the plane and it’s working direction is different, the squaring method and procedure is really the same like mirror image. As you know, Japanese plane direction is reverse direction with yours. I am not a Japanese, I am a Korean. Before Japanese attack and rulling era, we used the same direction pushing style plane like you and Chinese, but after Japanese rulling era, we lost our tools and skills. It’s somewhat long story, I want to comment later. Anyhow nowadays we are using Japanese tools and also some people started to use western tools. Personal reason, I learnet asian woodworking first, now I am interested in western tools and learning western style woodworking through your videos. I bought you book and video. I am really enjoying your books and videos. Nice to meet you in your blog and on-line.

I was reading , again, the blogs about the router planes, because I have recently bought a Stanley 71 router plane and I know that this blog is the best place in order to find all the details about fetling, sharpening etc.

I know it’s quite an old message but I couldn’t resist to comment. Well, with all due respect, I think that the English word for joinery is… joinery. Both harmos (αρμός – joint in English) and harmony (αρμονία – the perfect agreement/concord between jointed parts) are Greek words. The word harmony is common in many languages, with some variance in spelling, since there is no one word translation for it. On the other hand the word harmos is rarely used because in every language there is a corresponding word.

Finally, leaving the philology behind, I would like to say, like many other followers of the blog, a big THANK YOU for all the effort, the passion, the philosophy and the information you share about your craft and life in general. It’s simply invaluable.

Paul,

I just checked on E-Bay USA to buy a used Stanley but the prices here seems to be much higher than in the UK.

You should sale me one of your collection!

Bert

Bite the bullet and buy one there. It will still be a fraction of a high-ender ones and will last you a lifetime if you are 15 years old or older and use it daily six days a week as I have. If you pay $100 for one it is still less than I paid when I was 15 and it cost me a week’s wages. I’m still using it.

Hi Paul,

Just received my Stanley 71p. It is a very nice and new looking plane I would say. Got it off e-Bay and it came with extra cutters and a fence. Do I need to lap the sole like we normally do on the other planes i.e. bench planes? I guess what I’m asking is how do I get it tuned up?

Jugnu

Hi Paul… I am looking for the diamond plates you use as I want to see if your method of sharpening chisels is better than my present set-up. I grind a hollow-bevel first at around 25 degrees, and then hone a separate bevel at around 30 degrees. I don’t aim for the secondary bevel to be flat, but I do maintain two bevels. I note that your chisels for instance are almost like a bull-nose, You seem to get excellent results, but I can’t figure out how they cut. My analogy is comparing the rounded bow of a rowing-boat, with the sharp edge of a destroyer’s bow, which cleaves the water more easily.

It’s really nothing like that at all. What you describe doesn’t at all compare in sharpness. At the extreme end you reduce the incline to 1-degree and you indeed have the minimal resistance not better sharpness, but therein is the compromise, you have a non-viable edge that flexes like baking foil and or breaks as soon as it touches the wood. What we accept is what was established and never bettered over many centuries and that is the most practical edge is still 30-degrees. This is the easiest to establish and maintain and has the right balance between sharpness and resistance. We start all our sharpening for planes and chisels at 30-degrees and then drop off to whatever angle we want. You can have as large or as small a bevel as you want with the larger bevel fracturing the least and the smallest bevel fracturing the most.

Hi John,

I would like to challenge you to a friendly boat race. We will row one thousand meters. Looser buys the first round. I get the row boat and you can have the destroyer. I will give you a head start.

You call one boat sharp and the other round but in reality, hollow, flat or cambered the bevel angle at the edge is the same 30 degree sharpness. Ever ask yourself what is the point of a micro bevel on a hollow ground cutter? Why do I need to remove so much metal from the end of my cutter? When you look at it from the point of view of the sharpener it is to make sharpening easier by reducing the amount of metal to be removed between major sharpening. When you look at it from the point of the wood being cut it doesn’t know what lies behind the edge it only knows the very edge. So the wood only reacts to the first tiny bit of steel. The remaining steel (hollow ground, flat ground, cambered) is of minor import to the cutting action.

If you are interested in sharpening check out some of the “Japanese Style” sharpening videos on YouTube. The Japanese seem to uniformly recommend cambered edges. Carter Cutlery has some good ones. Try this one https://www.youtube.com/watch?v=KsUw4CmDwfA&list=PL054248E8627060B6

A cambered bevel has the following advantages over other types:

– Durability: An edge that is backed up by a cambered bevel will generally out last a flat or hollow bevel because it has more steel behind it. A flat bevel seems to loose it’s sharpness all at once where a cambered bevel does so more slowly.

– Chatter: Many people buy expensive thick blades thinking it will reduce chatter then hollow grind them removing much of their thickness near the edge where they need it most. Why? The wood doesn’t care what’s back there it has already been cut. (This is minor issue because as Paul has shown these cutters don’t chatter)

– Time: A major problem with micro bevels is returning to the exact same angle when honing. Getting the first micro bevel is relatively easy but to re-sharpen that same micro bevel your jig must be capable of exactly duplicating the original angles in both the horizontal and vertical plane. This is fiddly and time consuming. Did I say jig? What type? Who makes the best one? Am I using it right? Should you use stone, paper, diamonds? Ugh! Who needs it? As Paul has shown a cambered bevel can be easily produced and quickly reproduced without much fiddling about.

Best of luck.

HI Terry…

In a proper ‘boat race’, I think you would lose. I wouldn’t be using a destroyer of course, as a rowing skull is the ‘tool’ of choice and not a rowing boat. Even if we both used the same kind of boat I think you’d still lose! (Well at least, forty years ago you would have 🙂

I am seeing what you mean about the edge and the 30 degree sharpness. But by looks alone, a fine edge should still cut better than a rounded one.

Jigs:

I don’t use a jig, but if I did I’d keep a setting gauge (Such as I’ve seen on various Fora.) A small block of wood, with a small fence glued on it, at the right distance to obtain a repeat angle. My bevels don’t look like a blunt nosed boat, but rather a gentle curve that alters slightly to be around 30 degrees at the edge. Not exactly flat; that would be nigh impossible with freehand grinding. But any variation would be slight.

I have decided to use cheaper wet and dry papers to test Paul’s three surfaces method. I use only two stones at the moment, and I don’t strop. I remove the burr by flipping the chisel or iron over and flatting the face. I like to think my chisels and irons are still sharp enough to take the ‘nadgers’ off a gnat, in a split-second!

I have never used a Japanese Chisel, but I believe I am right in saying they are used in Japan with a single bevel, usually ground on a wheel. I can’t be sure about that of course.

Cheers.

Take care

JC,

Hello, î’m studying Fine wood works in Stratford and i ‘m desperately looking for a router plane stanley, preston or tyzak. I ‘m starting the carpenters craft competition so if any one has one that ï could buy for 35£ max. Please help me out !!

Thank you

Louis maurelet

Anyone got a spare router to help Louis out here?

Louis, please let us know of success so we can cancel the search for others wanting to help..

Hi Louis, sorry I only just found your message, my Dad was just over in Ireland and I could have picked one up on ebay and got him to bring it back to New Zealand on his way home. Did you manage to find one, on trademe or the likes? If not you could try one of Paul’s poor mans routers in the meantime.

I bought a Record 071 with just the pointed cutter.

I want to buy the stright ones of 1/2 and 1/4 but it seems quite impossible.

I try in all website all over the world but they had disapeared. Can anyone help me please?

Buy a replacement cutter made for the Veritas router plane, they fit the Record and Stanley 071 perfectly.

Hi Paul,

I have just come upon an opportunity to buy a Tyzack router for a reasonable price. It only comes with one cutter though. I had a quick search around the Internet for replacements but came up with nothing. Visually the Li-Nielson blades look similar, are you aware of if you can retro fit these?

I don’t know if the LN cutter will fit. If it doesn’t you might consider buying some square stock O1 hardened steel and making your own. It is a simple enough metal working task and the cutter can be fully formed and shaped and then hardened too using charcoal and a barbecue pit. Just a thought.

Thanks Paul, sounds like a fun project, especially if it gives me a tool for life!

I found a nearby source of 01 square rods in different thicknesses, and despite my reluctance to deal with very hot metal, the woodworker’s guide to metalworking (threeplanes.net/toolsteel.html), hardening and tempering the shaped annealed steel seems straightforward.

How on earth do I shape the 90 degree turn in the blade to get it to the right angle of presentation to the wood?

Not hard. I use a sledge as an anvil. Heat the steel through until red 3/4″ from the end and clamp in a vice and pull or hammer over. Refine it on the sledge face with a second 1 1/2 pound ball peen or whatever you have. You can also draw out the bevel on the sledge face too or you grind it. Better to hammer draw it really though. Reheat as needed. Remember it’s not 90 degrees but around 100.

Ah, once again I am satisfied by the answer, “I don’t know.” It takes a person of experience and integrity to use that answer.

I personally would buy the LN replacement blade of choice (they cost under $20, and only if they don’t fit the Preston or Tyzack would I resort to a barbecue pit, blow torch or my dear spouse’s oven.

Or, at least, wait until Summer is a distant memory, and rummage through Zada’s (grandfather’s) metal working tools to find one that would do the job.

Thank you for your perserverence in this issue, Mr. Sellers

PS: Oo! Oo! (Excitement!): There is a Veritas grooving attachment that will cut a double slit, enabling a fixed width (and length) groove near a work edge. Of course, all the parts would cost anywhere from $250 to $300 (with restraint on my part.) Mr. Lee would be very proud of the innovative spirit of his company.

Or, if Professor Sellers would take his poor man’s router plane and his rebate plane and meld them into a dado plane that we could make for $10 to $20, as long as we stick to the one width we normally work with (1/4″, 1/2″, 3/4″, or 7/8″). I’ve been looking for those used, but using a Krenov/lamination method would result in something that is my very own. Please. Some day?

Hi Paul,

I just purchased a Stanley No.71 with all the parts, plus more parts. I wonder what “tune up” process I should follow other than sharpening the cutters. Have you done a video or blog about this?

Thanks, Rob Morrison

Hi Paul,

Do you have any opinions on the Lie-Nielsen large router plane? Seems to have the typical Stanley design, would this matter? Or would you still prefer the Veritas? Thank you.

Jesse

I am sure it’s a decent plane as Lie Nielsen do make quality gear. I never understood why they dumbed down a good router plane design by leaving off the key features the Stanley 71 and Record 071 offered. Of course they are not compelled at all to manufacture true replication, and really it’s a good knock off of the Stanley when all said and done and that’s what they’ve been good at. I don’t usually get into comparing makers but here I give my two pence worth. None of the planes manufactured have adjusters that can be trusted as to micro-adjusting depths accurately so don’t think a quarter turn gives any kind of exactness in terms of replication. It doesn’t. Inevitably a 1/4 turn can vary markedly even in the same plane so all depth adjusters an ALL router planes really rely on our intuitiveness no matter what the printed word says. Of course the Stanley had guides and depth controls that Lie Nielsen left off by removing the stem at the rear of the hump. Don’t be deceived by the picture on their website showing the one router plane cutting a groove in the narrow edge of a board. They are using a different router plane for this and so the suggestion is that the large router plane is doing the work when in reality they are not one and the same plane. Using the router with the hump and without the stem holding a bridging piece, the fore end of the plane will roll forward because it is unsupported into the cut and gouge the bottom of the groove uncontrollably. I am sure this was likely cost cutting and the reality that for 95% of work you don’t generally use it for general work. The true benefit of the hump, which is missing from the Veritas model I am sorry to say, is when cutting stopped housings and stopped dadoes. When you make passes with a humpless router the waste bits being removed gather at the fore end of the plane at the end of the housing. This then jars the plane and can damage the rim of the recess because these shavings are trapped and have no escapement; the primary purpose of the hump. I suspect that you could find a little-used Stanley or Record in complete or as new condition for a comparable price via eBay and have all you need. I think that that is worth looking for. That said, if you install a wooden sole, which I do recommend, the benefit of the hump is negated until you remove the wooden sole for a particular task.

Paul,

Thank you for your very insightful response, I greatly appreciate your thoughts on this matter. I plan to install a wooden sole on any router I purchase, no matter the brand. I wasn’t considering the open mouth in the beginning, but perhaps it wouldn’t be a bad idea to have, seeing as I can only afford one at the moment, since I plan to add the wooden sole. I have been keeping an eye out for these style planes on ebay, they average $100 usd, buy-it-now, plus shipping. I don’t agree with most sellers on their pricing, seeing the condition some are in, however, there are plenty of clean ones on ebay selling for a good price. It’s an internal battle I’m having of new or old. Thank you again for all your help and insight, it is very much appreciated.

Jesse

Hi Paul, I tried to add a wooden sole to my Stanley 70 1/2, as per instructions from your new book and accompanying DVD. After all the work was done, I noticed that the cutter doesn’t reach below the sole anymore. How can this be? Was the cutter not the original one to begin with perhaps?

Should say ‘Stanley 71 1/2’ of course.

Have you turned the adjuster/winding knob the opposite way up so that it sends the cutter to a deeper level?

That solved it! Thank you very much! I thought the letters on the knob were supposed to be on top. Stupid mistake. I also took down the thickness of my wooden sole to 10 mm, so now I have around 9 mm cutting depth. Probably enough for most work, except maybe the apron recess on the new workbench.

It can of course be used both ways, Stijn, so you were not necessarily wrong, you just didn’t know.

That’s an interesting way of looking at it. It’s not wrong, it’s just different 🙂 Anyway, I really appreciate it that you took the time to reply. That’s not an easy task with so many followers.

As much as I’d like to get my hands on a Preston, I doubt that will ever happen. I’ve been so discouraged with buying tools on eBay here in the U.S., I almost bought a new one but couldn’t decide between Veritas or LN. In my relentless search, I ran across a router based on the Preston design. Made by Walke Moore in U.S., it appears to be a good tool. However, at $300, I think it’s priced much too high and unavailable for a hands-on examination (unless you buy one).

Paul, have you seen this router and what are your thoughts?

http://www.walkemooretools.com/shop/router-plane-model-2500/

Best regards,

Carol

I can’t give thoughts on something that is not in production and cannot therefore be tested Carol. It’s been a long time since these were available. Of course the Veritas and the Liw Nielsen versions are great options at half the price too. I have used and tested both.

Hello Paul,

I just purchased an old English wooden router(stepped block style) and was wondering if you have any tips or videos on how to tune those up? All searches just kept leading me to this page. Thanks!

I think the tool collectors are running up the price on Stanley tools. A 71 router is going for $100 on ebay. I can’t seen to justify that when a new Veritas is selling for just a bit more from Lee Valley. What are your thoughts? Am I missing something?

Yes, there is the single factor of the hump at the front of the Stanley and Record routers. This most useful at the end of stopped housings and dadoes because the wood is not bumped against the end of the housing and thus potentially damaging the corner area.

Thank you for the reply. As it just so happens I won an auction on ebay for a Stanley 71 1\2 for just a bit over $100 from England.

Paul have you heard of the new Walke Moore router plane that is fashion after the Preston router plane. If you can could do a review. I do know that it is not cheap at $315,00.but that is the closest to the Preston one. Also as of today they are sold out.

As far as I can see they have either always been sold out or they are not really in production. You could consider a Lie Nielsen or a Veritas. They work just as well and cost half the price. I probably shouldn’t and wouldn’t do a review on a tool that’s not readily available.