Myth and mystery surrounding plane and chisel bevels

For more information on planes, see our beginner site Common Woodworking.

Actually that only became a truer statement in more recent decades. We woodworkers actually sharpened to what we felt we wanted and not what we were told to sharpen to. We woodworkers decided to sharpen a chisel to task so that if we were working on one wood or doing one task, we changed the bevel by eye in a fraction of a minute and got on with the work. Some chisels we sharpened to 35-degrees, but we never ever checked any angle with a protractor, but you can if you want to and I think new woodworkers should check themselves from time to time. Sometimes we changed it to 25 degrees and that worked so effectively for hand paring soft wood. The reality is that there are good and practical reasons that we do sharpen or hone to around 30-degrees for general woodworking, but they may not be what you think they are. For the main part, certainly throughout history, this 30-degree bevel was merely the angle to shoot for, rarely was it gauged and it was not a legalistic and rigid definitive angle. How often we teach this as an absolute in the same way that we say you must freehand sharpen or you must always use a honing guide. The disadvantage of using a honing guide for me is you can’t create the macro camber I like as a bevel. The advantage is you are assured you get the exact bevel you want. On the other hand it can be a bit slower, quite a bit, and it’s more fiddly, but perhaps not overly so because I am told you can “get quick at it.” All in all there are reasons for both freehand and guide held sharpening methods ,so then it’s a matter of personal choice.

This plane has relief of only 3-degrees less than the bedded angle of the pane and it cuts very nicely; as well as one honed to 30-degrees. Wow! That’s freeing!

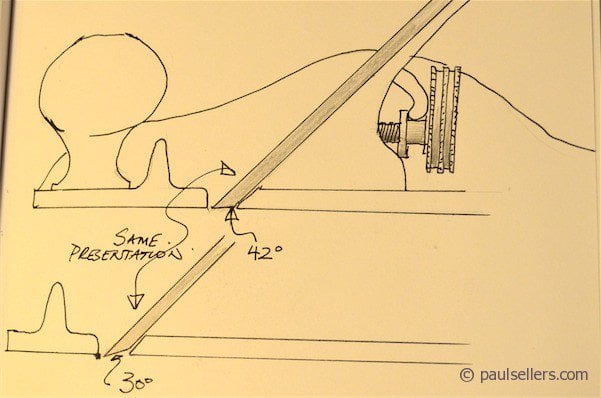

Let me ask you a question. If a bevel-down plane has bedded angle at 44-45-degrees, like all of the Bailey-pattern bench planes and many others are, what difference does it make to the cutting edge if the plane is sharpened at an angle more than 30 and less than 44 to 45-degrees? Surely, as long as the bevel is underneath, it makes no difference to the presentation of the cutting angle to the surface of the wood, right?

At the shows, this was a question I asked and indeed answered. It demystified what was the unasked question, which was who said it had to be dead-on 30-degrees? As I said, the angle of presentation remains identical because the bevel is on the reverse side of the cutting iron and not on top.

The fact is it’s just good sense to have something to shoot for and 30-degrees is a quite practical angle to establish. I never use a honing guide unless something has gone wildly out of kilter. On the other hand, in my classes, I have honing guides for people to use as some prefer to at least start out that way. Ultimately, all of my students end up freehand sharpening because of the speed and efficiency and indeed variability of creating say an instant change to a 30-degree bevel to make it 40-degrees for chopping mortises in certain types of wood or something like that instead of a hand paring angle. Most people have chisels for chopping and others for paring as they accumulate more and more tools.

This protractor shows the exact angle we ground and honed at. No secondary- or micro-bevels.

Straightedge showing the honed primary bevel in relation to the sole and showing a 3-degree relief at the back edge of the bevel.

The other thing is that it is easier to sharpen around 30-degrees than it is at 40-degrees because of the steepness and control. If you are freehand sharpening and you are anywhere between 30-40-degrees, the plane’s cutting edge will of course last longer and the plane will cut with exactly the same pressure because the angle of presentation to the wood is identical, regardless of bevel angle. It’s also the same as is on bevel-up planes. So it makes no difference in terms of pressure and resistance. That said, there are physical dynamics at play with bevel-up planes and that’s to do with alignment of the cutting iron to give more inline direct thrust, so you cannot dismiss the efficacy of the bevel-up planes either. I don’t think that its an either other situation and I do like bevel-up planes. You don’t have to get bogged down with infinite angles to bevels on planes and should leave yourself with options for change. You are free to sharpen your bevel-down planes with infinite variability. In freehand sharpening, this becomes essential and it makes little difference to the work you are planing so enjoy the freedom whether you use a honing guide or freehand your cutting edges. Try it, let me know what you think. Oh, and by the way. Three planes I bought recently that were old 70-80 years at least, and craftsman owned too, had macro cambers that started at 35-degrees and dropped in an elipse to around 20-degrees. I see that fairly frequently.More on chisels to follow.

My question on blade sharpening is, How does these newer grades of steel used in the blades effect the angle of sharpening. Example, I have heard that A2 chisels prefer 30* due to the chemistry makeup of the material. I was afraid to alter them much. I hear they are harder to sharpen (taking longer).

Let me say this. I am not advocating steeper angles as such. Just that we can get caught up in the exactness or intolerance of other angles and forget that it doesn’t have to be something so rigid. Sharpening by freehand methods relies on that certain flex and freedom of movement that allows you to be more interactive and even proactive, but if someone says it has to be exactly 30-degrees or whatever, we are suddenly bogged down with the legalities to the point we are suddenly locked in to something we didn’t altogether think through. It’s harder to sharpen at the steeper angle, or at least I found it harder, even though I used the honing guide in my experiments so that I could guaranteed exact angles and used a block of wood charged with polishing compound to prevent back curl normally associated on the strop that creates further increase on the bevel at the actual cutting edge of the chisel that would render the cutting edge ineffective.

As to A2 steel, I havent tried A2 steel for this at all so I can’t say. Sorry.

I think you are on to something there, Paul, but I also think there is more to the story.

First, the wear bevel. When you use a plane, a convex bevel behind the edge will develop, depending on the type of wood and the grain orientation. Professor Kato in Japan did research to this with electron microscopes and force transducers on his test setup.(http://planetuning.infillplane.com/html/review_of_cap_iron_study.html)

After a while the vertical force changed from negative (pulling the blade into the wood) to positive (pushing the blade out). The latter is not very conductive to handplaning efficiency of course. So, if you start with very little clearance allready, I think you will reach that point of too little clearance sooner?

Second.Planing endgrain is another thing. I did some tests too a while back and like you, with a FRESHLY SHARPENED blade I couldn’t see any difference in long grain planing. Somewhere around 2 or 3 degrees clearance I started to see some burnishing effect, because of the fiber spring back I presume. But lately when I did the same test on endgrain, I started to see burnishing marks when I went form 10 to 5 degrees clearance angle. So endgrain seems to be more critical.

Anyway, on a plane I usually shoot for something like 30 degrees honing angle, because of longlivity of the edge. My edges don’t usually fail because of lack of support (crumbling or folding edges) but because they just get worn and rounded, a wear bevel so to speak. So I start with a healthy dose of clearance.

I think all of that’s where we are really. The point of course is if the edge fractures at that critical point you end up riding the rounded edge, and so it is more to do with what was developed by practical actuality in use than scientific exploration, but the end results can be proven by science. I never thought that people sharpened to 30-degrees without reason but because it was so highly practical. I have dismantled hundreds and hundreds of planes through the years and they are all between 30-35 at the cutting edge regardless of pitch presentation (Bedded angle).

When old planes finally come to me they are usually all over the place. I have this little theory that most of them didn’t came straight from a knowledgable craftsman, but went through the bodgers first 🙂

30- 35 degrees sounds like a plan. And I agree completely that it isn’t very critical at all.

I think the other thing is that the top and bottom or underside of the iron, the one with the bevel on, sort of centralizes the presentation of the cutting edge to the wood and so equalises the pressure to both side in the same way a knife cuts into or through a substance with equal pressure from both sides and this supports the steel as it passes into or over the wood. Very practical really.

Once again the diagram did it for me. I had been trying to wrap my head around the importance of bevel angle on a bevel down plane iron and was having trouble with the visual. Paul’s shop drawing snapped it into focus.

And it makes a practical difference for me. While I’m not at ALL sure I can hold a precise 25 degree angle while hand sharpening an iron I’m PRETTY sure I can keep it to “between 42 and 20 degrees” even as a beginner. Hand sharpening here I come.

I completely agree. The best thing that ever happened to me was watching Paul’s method for sharpening freehand. Everyone made such a huge deal out of the correct bevel angle abd micro bevels and blah blah blah that it took tons of equipment, set up time, etc just to sharpen one tool. After switching to Paul’s method, I’ve never not had a tool not cut wood or shave hair since I started. I’ve never checked a bevel and do it by eye. The wood truly doesn’t seem to know the difference between the approximate 30-40 deg bevel that’s on my plane or chisel blade, it just cuts with ease because its sharp. End of story. In the couple years I’ve been woodworking, I realize sometimes we get so into detail on a particular facet we forget what the end result is. People spend more time perfecting their bevel on their tools than working wood with the tools. I can freehand a tool with an approximate 30-40 bevel in approx 30 seconds honed to a mirror razor sharp edge and get right back to work.

Lately I’ve been drinking a lot of the Paul Seller’s Kool Aid (generally, very refreshing!)- but, I admit, I do have trouble with this statement:

“If a bevel-down plane has bedded angle at 44-45-degrees, like all of the Bailey-pattern bench planes and many others are, what difference does it make to the cutting edge if the plane is sharpened at an angle more than 30 and less than 44 to 45-degrees? Surely, as long as the bevel is underneath, it makes no difference to the presentation of the cutting angle to the surface of the wood, right?”

So, a blade honed to a 45 degree bevel will cut as well as a 30 degree bevel? I think our experience doesn’t agree with this. The obvious answer is what we all know. Blades honed to more acute angles cut better but stay sharp less long. O-1 steel tolerates more acute sharpening vs. A-2 or PM blades but the latter two stay sharp longer at a somewhat less acute hone angle. However, the plane’s angle of attack surely matters too. Lower gives cleaner cuts but with the potential for greater tear-out – the reverse with higher “pitches.”

Thanks Mark. I think my follow up comments help with this if you have read them, but I am not advocating anyone changes pitch here, just that it doesn’t make much of any difference to the blade presentation if the blade presentation is unalterably fixed and the bevel is underneath.

I don’t get into harder steels and thick irons because I found the irons present unnecessary problems. The difference in edge retention and durability was only marginal if I could even detect them and so it all countered the freedom I have from not using machine methods that grind off more steel that’s so much harder. For me, it’s more about freedom from legalism than anything. Fact of the matter is this. It takes only about a minute to sharpen a chisel or a plane iron. I think that that’s an important fact that guides me in my evaluation and decision making. Thin, Chromium Vanadium irons have worked for many decades now and I feel that they work really well.

Paul, thanks again for the sharing of knowledge gained from experience! If we factor in the incredible ability of humans to adjust, especially with tools not rigidly set up ( chisels, engraving burins, drawknife, native American crooked knife etc.), then our most useful tool becomes experience. A short story. As a farrier, horseshoer- blacksmith, I had the pleasure of watching Sir Edward Martin, Scotland’s world famous draft horse farrier, hand make draft shoes using no measuring tools of any kind. Faster than anyone I’ve ever watched. When he finished. All four shoes were identical! You could spit through the nail holes:-o Ahhh!! Craftsmanship of the masters.

Note that in the case of bevel down planes the angle of attack (what Paul calls presentation angle) is fixed. Sharpening to a lower angle leads to edge failure faster than it leads to freer cutting. Approaching the cutting angle (bedding angle, angle of attack, presentation angle) leads to riding the wear bevel sooner. The range in between where you have an edge that cuts well and lasts a long time is huge, with the median somewhere around 30°. That’s all. 30° is a good, practical angle, but not something written in stone.

Hi Paul. Thanks for a very interesting article. I wonder sometimes if humans had no choice but to mindfully consider the reason they did anything, anytime they do it, what would happen? Zen Buddhism or Mass Murder?

Great article. I also enjoy your YouTube videos very much. I only do woodworking as a hobby but you have helped me immensely with the little I do. Thanks from Parma, Ohio USA

I teach woodworking to middle school kids. So the hand sharpening has made things much simpler, calmer, quieter and less costly. When I went to look at the old Stanley planes I bought to see if they needed sharpening, well they all did. Using Paul’s method and my set old set of Arkansas stones, it took me an average of 5 minutes to sharpen. That’s from picking it up, examining the edge, settings etc, to finally reassembling the plane. Beats the heck out of trying to set up a sharpening jig etc. Paul I like your calm, no nonsense KISS principles (keep it simple st#pid). Next class I demoed how easy sharpening is to them. Now they will be able to do this themselves. Thanks Paul.

I’m new to hand planes and am learning a lot though various groups and post. Paul Sellers seems to be an acknowledged expert on hand planes and many other things. I accept that he is… however; every time I have a specific question which I search for on the internet, Paul Sellers answers seem to be general, non specific and non committal. A lot of, “it depends.” Okay, I can accept that there are lots of variables, but when I ask a question such as “What angle should I hone my new Lie-Nielson apron plane?” it would be nice to get a straight forward answer such as “start at 25, then add a secondary bevel at…” I trust you Paul, give me straight up short answers so I can get to my workshop and apply/learn. I like the “it depends” stuff somewhat, but cut to the chase with the first part of your answer then elaborate… Thank you for your time and expertise.

When you have worked with wood for a few months you will a few “it depends” into your sentences I am sure. I’ll reserve the right to use them so that others will understand that things do depend on the grain, the wood type, the density and then two dozen other things too. I think most viewers have learned to filter out the drone of my voice these days but their ears prick up for the salient points.

well said

Hi Phil,

I have a question about old wooden plane irons:

I’m now cleaning an old coffin, single iron, and I had noticed that the iron cutting edge isn’t straight or convex, but concave. The same, with this plane I received a little coffin, 15 cm long, single iron, concave at the edge: do you think that are the results of sharpening on narrow stones that causes this? Or some sort of inaccuracy?

Thanks very much,

Valerio.

Sorry, I would say “Hi Paul”. But also Phil deserve a greet.