Planecraft Revisited

I want to reinforce what I started yesterday, to take away doubt and clear any fogginess. Many people expressed their views and naturally there are many persuasive considerations to think through that make sense. By this we can better make an educated evaluation I think.

Why do I feel so good about older planes?

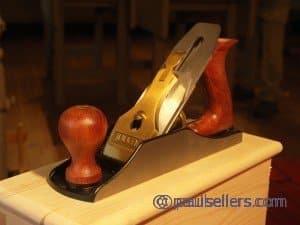

I have owned several well-made smoothing planes including all of the top of the range plane makers, but not including the planes like master engineers such as Karl Holtey.

I also own planes by Norris, Spiers and Mathieson, noted plane makers of the 1800′s who at one were held in the highest regard. The more modern planes are all exceedingly heavy and sometimes there can be an occasional place for that I think. I also know this; every time I pull one of the heavy, well engineered planes from the shelves, within a few minutes I find myself ignoring it and reaching for any one of half a dozen #4 Stanleys or Records or even a 4 1/2.

As you progress your development with planes you will realise that most planing does not necessitate the kind of ‘bull-dogging-to-task’ most images in magazines, catalogues and books depict. This will be contrary to all you were taught in school, by woodworking gurus and by following DVDs and online broadcast, magazine articles and such. Yes, of course a firm and confident grip is necessary, but playing the muscleman has nothing to do with sensing the plane and the wood through the plane’s body and the cutting edge within and moving according to naturally developed intuition as you feel for change in the grain.

Sometimes we have false expectations and when we meet the new-day woodworking sales outlets and staff, you are all too often presented with a very false representation of real woodworking. A stick of maple held in a vise with perfect grain orientation is far from what you get on the rim of a box or the frame of a door. This is not really very realistic at all, but at the bench at a show the demo’s can look very convincing. All I ask is that you be appraised of an alternative possibility and do not be intimidated by doubts that you can fine tune a working plane whether it be new or not.

Though for me, many of my planing techniques were initially passed to me over a number of months when I first started my apprenticeship, I am very aware that my real growth came when I took personal interest to maximise the flexibility of using the plane. I never did bulldog my plane to the work as many advocates do and say to do, because I was told not to because I needed “to feel for the cutting edge in relation to the grain I was negotiating second by second.” Who says that to you today except me?

The post yesterday was more about the softness of using old planes. Old doesn’t affect us like say a computer might or a computer game both of which change daily and become obsolete in a matter of a very short time. Isn’t it an amazing thing that the Stanley number 4 was berthed in 1867 and that no modern plane maker has come up with something better.

Doesn’t it amaze you that something could last through a century and a half and only the materials have changed a little bit. I am amazed that I can pick up an old and discarded smoothing plane a hundred years old and have it planing any wood within fifteen minutes or less. I had enough emails since yesterday from those who support what i am saying. I’d like to hear from more people about both your successes and your failures. How you overcame your shortfalls and how you would advise someone in relation to buying a plane.

Hi, Paul. I will bite at your invitation. I had a post-1980s Stanley No. 4. It said “Made In USA”. The frog and sole were painted where they contacted, but were never milled flat. It needed flattening, but I had no means to do it. Until a couple years ago, if I couldn’t use a cheap chisel or pocket knife, there was no smoothing done. I have replaced No. 4 with a Veritas BULA smoother, a Bailey No.6 from Leach or HyperKitten, and a No.3 from eBay that is surprising decent. My favorite is a MillerFalls No.57 mutant block plane. However, what I really hate is sharpening.

I think just for the cost difference I would give an old Stanley a shot. Spend anywhere from $10 to $50 and you have a good plane to clean ,sharpen and work with. By the time you finish you know that plane inside and out. When you make that first full shaving you will have such a sense of accomplishment.

My wife bought me a Lie Nielson #4 last Christmas. Is it a nice plane? Sure is. Is it better than my Stanley? No. It’s definitely heavier. You feel that after 5 minutes of use. I still reach for my Stanley. It feels good in my hands. Just knowing people used it 60 to 80 ago to make a living or just build their own furniture is cool. You know that tool can do the job. Just take some time to learn to use it.

For the price of the Lie Nielson you could buy a whole set of used, broken in, proven tools. It’s nice to buy new but it isn’t necessary. As more than one tool guroo has said, buy the best you can afford.

Hi Paul,

I wish I had more to share about the success of my hand plane adventure. But for the past year my schedule has not been conducive to having very much free time in my workshop.

After seeing you for the first time last January I became interested in your style of woodworking. At that time I knew very little about hand planes. Taking your advise I now have a wonderful collection of old stanley planes that I am looking forward to using in the near future.

I must say that even though this,past year has not allowed me very much free time in my workshop I enjoy the adventure of finding these treasures and fantasizing about what stories they could tell. And what stories we can make together!

From one of your recent post I now know that many of these are not your favorites. I did have an opportunity to purchase many Bedrocks. And along with that find I also learned the history of the previous owner as I purchased them from his son. I understand what you are saying when you speak about the old tools. It is kind of like getting reacquainted with an old friend.

Paul,

For the most part I agree with you, but I think you are forgetting one thing. You became an apprentice at 15 or so, isn’t that right. You were exposed from the beginning to planes that were well tuned and performing well. Therefore, you knew what to shoot for and had skilled craftsman there to help you in person as you began tuning or maintaining planes. Many of us didn’t have that opportunity. What seems easy to you know is daunting at the beginning.

I think the best option is to take a class on restoring a Stanley Bailey plane. After that, I think you can buy and restore bench planes and be just as happy as it you’d spent much more on new premium planes. Failing that, I think it is best to buy one new premium plane and then purchase vintage planes as you want them.

I had no one to help me and nothing except books and magazines. I bought one plane, a Lee Valley bevel up smoother. It was a revelation. It gave me the experience I needed to buy and restore vintage planes. I know many disagree, but I still think there are advantages to owning one bevel up plane with multiple blades that have different bevel angles.

“I am very aware that my real growth came when I took personal interest to maximise the flexibility of using the plane.”

Well said and that applies to not just the plane, but hand tools in general.

Paul,

A while ago I asked you to discuss more about your apprenticeship when you were a boy. Every now and then you mention something such as, “…to feel for the cutting edge in relation to the grain I was negotiating second by second.” Such statements give me better insights to my progress in working wood.

As for some of my failures, sometimes I see some fibers getting wedged between the cutting iron and the cap iron of my #3 I bought on eBay. I think it’s because the surface of the cap iron that presses against the cutting iron near the blade is ground at the wrong angle. I may be to blame for this since I did give this area some attention. I’m not sure how to fix this without doing more harm. Another shortfall I had was in sharpening the cutting irons. I found when I did it freehand I’d end up with the blade out of square. I also ended up with a “thick iron”. So I invested in a MK.II honing guide from Veritas. It made all the difference. I would advise those who have little or no experience to do the same.

As for my success, I found a cheap plane at my grandfather’s house. It has a plastic tote and front knob. I probably would never buy such a plane on EBay. I’ve had it some time but never knew how to use it until I started following your blog and Masterclass series. Now it takes shavings with much satisfaction. I did the same with a block plane I bought from Sears a few years ago. Even cheap planes can be useful when sharpened and tuned up properly.

John

Hi John,

I agree about what you said regarding cheap planes can be useful when tuned up, I recently was given a faithful no 4 plane probably cost about £20, I took a bit of time to sharpen and tune up and now it is every bit as good as one of my Stanley’s, it a pleasure using it!

Paul I tend to agree with Andy. After purchasing several old planes that I was unable to properly tune I became discouraged and ultimately purchased a premium plane that was capable of making up for my short comings. After I gained more experience through trial and error, I realized that the planes were fine. I think that sometimes premium tools can compensate for lack of ability. I sure wish there were more apprenticeship programs in my area. With that said, I still go back and re-read your articles and as my skill level increases I take something new from the article every time.

Thanks for your dedication

Many of the things said in favor of the new planes seemed to have a whiff of consumerism, which like other unpleasant smells, is often denied. One of the basic tenants of living in a disposable society is that old things are, a priori, inferior. So, you spend $ for an old plane, and time/energy to rehab it, and what are you left with? An OLD INFERIOR tool. Then we are confronted with this Maverick [a real longhorn] who says, “no, it’s not about buying the right/best/most expensive tool. It’s about caring about your craft, about going with the grain.” Well, shoot, the entire wood-hobby industry doesn’t want to hear that. There’s no money in it. And if I spent $400 on a plane, I don’t want to hear it either.

Another thing that has worked on my brain has been a kind of bling factor. The new planes are SO pretty. Who knew you could lust after a tool? And the manufacturing and engineering is pretty advanced, so there’s curiosity factor–what have those guy at Veritas….Lie Neilson thought up now? But as a practical matter, there was little reassurance in buying the new planes. They have to be sharpened and adjusted just like the old planes. When I first started with a Grizzly #5 Jack [made in India], I couldn’t make the darn thing work. There was nothing wrong with the plane, and likely I would have had similar problems with my LN 5-1/2, had I purchased it instead of the Grizzly. Learning to sharpen properly was an eye opener, together with all the videos on fettling a plane. The process of learning how to repair and set up the tool seemed somehow to help me understand how to use it. The Grizzly is now set up as my scrub plane, and it works extremely well in that role. Grampa’s block plane (with the iron finally right side up) is now a joy to use, especially on end grain. When I look back at all those mistakes, and now see that I can get an old plane up and running in less than an hour, that satisfaction and sense of accomplishment help keep me motivated through my current set of mistakes working with the wood itself.

I guess what this boils down to is that it will be impossible for anyone to do good work with hand tools without a solid knowledge of how they work. And having that knowledge gives one the freedom to choose: 400$ vs 40$. I am certainly no expert, but I would be hard pressed to tell the difference between two boards, one surfaced with my Stanley 4-1/2 and the other done with my Veritas bevel-up smoother.

When Paul talked about exploring his mistakes, I realized that he was still learning, still teaching himself his craft. What a great model for a teacher. When he talks about making his living working with wood, I just thank my lucky stars that it’s him, not me. I’d have starved to death years ago, especially if I were paying 400$ for a plane and 250$ for a saw (and so on).

I hear what you’re saying, but my experience is that my plane won’t shave if I don’t “bulldog” it. Probably my plane was originally dull. Now that I can sharpen well, its just bad habit or not sharpening frequently enough (laziness). I’ll have to experiment. Over the years have you developed a method to teach your students how to be sensitive to the plane or is being aware sufficient?

I don’t understand the “bulldoging” thing. Never heard someone doing that with a New or Old plane. Unless they didn’t know the blade was dull.

Bulldogging is a term I use to describe how people lock the totes rigidly and then convey that to the whole body. People in class do this because it’s what they were exposed to before they came and think its right. They soon learn to loosen up a little and feel more from the plane as they work it to the wood. It doesn’t take too long before they gain the confidence they need to relax more in their planecraft and then they ease through the process. I think if you look at images of many people planing they do seem to convey this type of muscling the plane to the wood.

OK, that makes sense. I think some of that comes from the thought that you need a low bench because you need to put so much weight on the plane. though, if you put weight down on the plane, there is no weight behind the plane. funny how physics works.

One thing I think is very much misleading is exactly what you say there and that is that you have to press the wood to the surface throughout the stroke. zThats far from true and we are about to do a vid that proves some of what I say and that is a sharp, well set plane pulls itself to the wood. if my experiments are conclusive we will be able to help people all the more. If I am wrong, I will just be embarrassed a bit.

Let me make it clear that I wasn’t advocating that you need to push down on the plane. I was simply referring to the images and articles that have been seen about using hand planes. And stating that is you push down , you lose the force to push forward.

Totally agree Paul. I spent last weekend bringing eleven Stanley and Record #7’s back to life from their previous states of dusty blocks of flaky rust. I get a thrill knowing these will now be passed on to people who will hopefully discover their little idiosyncrasies and will then get them working superbly.

Appreciate your advice regarding essential tools, etc. For example, your video about sharpening the plane to 250 grit demonstrated that we can achieve good work with just the few tools that many of us already have. It dispels the doubt and fogginess I contract while thumbing through catalogs full of expensive ‘essential’ tools. Wood working is fun again and I’ve been spending more time in the wood shop lately : ).

Well, I am definitely in the used-plane camp. I think I have more planes than I probably need, and I think I spent under 150 USD for all of them. I have Stanleys’ 4, 4-1/2 (actually two of these), 5-1/2, and 6. My overriding deciding factor for buying used was $$$, although I might consider going into the hole for a Veritas small bevel up smoother. It just looks like a fun little plane.

My big success I think is when I tuned up my 3rd plane. I told myself, ok I’m just going to do the bare minimum amount of work on it this time and see what I end up with. So I cleaned and lubed it, lightly flattened the sole (basically just focusing on the mouth area), and flattened the iron back. And sharpened of course. It ended up taking full-width shavings as thin as I pleased, and they fed out of the body perfectly without bunching up. I lightly sanded the handles so that they felt nice and smooth again and gave them a shellacking, but I left the previous owner’s initials on the tote which were “tattooed” on as a bunch of tiny little dots. I can feel them whenever I use the plane.

I think the biggest setbacks are when you have convex surfaces that must be flattened. I learned the hard way that taking these surfaces straight to the granite plate is futile since you’re just rocking it side to side on the bulge. All you end up with are sore fingers and a still-convex iron back that is now thinner. Then the cap iron will have gaps that you just can’t seem to close up. What I do now is take a Dremel and grind the slightest concavity into the back, up to the slot. I do this slowly a little at a time, occasionally taking a few swipes on the granite to verify the wear pattern. Then flatten as usual. It’s a crude method but it seems to work.

Thanks for this and the insights you brought. I hadn’t thought of the Dremel tool.

Hi all,

I’ve purchased several used planes maily because practically no new tool comes ready for use straight from the box. You have to know (or at least try to learn) how to set, sharpen and use it. And a new tool becomes dull in a while, so you have to fiddle with it. It may also need some filing to make it smoother or to ease a hindered adjustment from factory.

There are lots of information available on how to fettle a plane, more than necessary, you just have to start doing it. It’s not so difficult, but not everyone likes to fix old tools, and not everyone can diferentiate clearly what is usefull on eBay from the crap, but it is doable and with some care the chances of buying a lemon are small.

I also have some new, modern planes, but most of my planes are the good old Stanleys and Records.

Paul, I have to tell you that 15yrs. ago I bought a craftsman no.4 smoother at a flea market hoping to one day figure out how to use it I have never had any training other than those magazines that seem to constantly contradict each other on styles and methods. Sure I came across books from Tage Frid and others but when I learned about some of the great ones such as Sam Maloof not having any training I thought my goodness how do you do it? What a revelation it has been to see your real and humble training that you have given us. I now can sharpen my plane blades, chisels and use that old plane which I restored and fettled myself. I now buy planes on e-bay and would not consider a new plane, sure they are pretty and some seem to worship them, but I want to use them and feel comfortable doing it. There is just something about using a well worn or say a broken in tool. Thank you for what you do and your insights from a real woodworking career, I have learned more from you and your style of work than anything else I have seen or done. I also want to wish you happy birthday—–thanks.

Paul another great post, it does appear more people are getting into Hand Tools than a few years back when the “Norm” craze and Delta Tools was the only way to go. I was one of those myself and will not take anything away from Norm Abram who I have personally met and spent 3 1/2 hours on a plane with him from Boston to Atlanta. He is a really humble and nice man IMO.

Having said that as I have all ways had an interest in Hand Tools but knew very little about them or how they worked etc. So when I retired in 2009 after 40 years in Corporate America in the Aluminum Industry I was really wanting to start working wood. I have some physical limitations from some injury’s over the years and quite frankly was afraid of hurting myself. Also being retired my income went downhill quick and for the 1st time in my adult life had to learn to budget and prioritize. The solution was very simple “hand tools” so I could continue with my favorite hobby, working wood.

When I first started to use a plane my results were less than stellar, my chisels would hardly cut butter and my handsaws was worse than that. So not having $300 – $400 to lay out for a new plane I had to settle for vintage. I will add I know you buy a lot off of E – Bay unfortunately I have been burnt a few times which has left a bad taste in my mouth and I know part of it is my fault not knowing the questions to ask and what to look for. A few of my friends gave me some tools to get me started and from there I buy only from a S & S Forum I belong to and frequent. I wanted to know not only what the history behind some of these tools might have been but what made them tick. That is where I taught myself what and how to fettle a plane. One of the most important thing in the learning curve is learn how to sharpen properly. Gosh knows I probably dulled more blades than not until I learned the what to do.

I have used and tried the new planes but I still like the vintage better, maybe it is because I forced myself to learn how to properly tune and use the tool. Like some one else mentioned the money saved from the new plane verse’s old can be used for other tools or wood.

Keep up the good work and looking forward to an exciting 2014 !

Steve

As requested, successes and failures:

1. Brand new Clifton #3 and #5. Useless until I learned to sharpen. Once I could sharpen, I loved them except for the cost. The #3 is still my best cutting plane, bar none. Later when I tried Paul’s lightweight Baileys, I came to realize how heavy these Clifton bedrocks are, but I don’t think it bothers me as much as it does Paul, probably because I’ve not put in as many hours. I wish these planes didn’t have the funky “quick access” cap irons.

Lesson learned and suggestion: If you are new to sharpening and fettling a plane and have no confidence in the plane, think about a sharpening jig like the eclipse jig just to get started. You can then machine the edge onto the iron with the jig and have confidence. If the edge is there, the plane will always cut at some level. You can then move on to learn Paul’s sharpening method and to refine the plane. On the other hand, you might get sharp with Pauls method right way. It isn’t that hard. But, if you have questions/doubts. don’t hesitate to do the jig. You’ll use the jig occasionally to square up and take out nicks. It isn’t a waste or a shame. You’ll feel “set free” when you learn Paul’s jigless method later.

2. Old Bailey #8, heavily rusted. $35 at a flea market. I was afraid I wouldn’t get the screws loose. I did, and bought a screw kit from stanley (no longer available as of a few years ago?) and got it to work. Unfortunately, the blade was useless and I bought a Hock blade. The Hock was too thick to allow the depth adjuster to engage correctly. I fixed this (yell if you need to know how). I like this plane but have trouble that the lateral adjustment causes the blade to walk shallower/deeper too much. I never fixed that annoyance.

Lesson learned: On this and other old planes, the biggest reason for failure for me has been pitted irons. This will usually be below and right at the cap iron. Even if you want a thick blade, be prepared that it may not really function right in some planes. I’ll likely not buy a thick blade again.

3. Various spokeshaves and irons for other old planes: I was unable to flatten the backs in some cases. The iron would grind quickly at first, but then it seemed to bog down and I’d get off less and less material for the amount of time spent. I’ve worked on sandpaper glued to granite blocks and on diamond plates as coarse as the DMT extra coarse. But, some irons just wouldn’t flatten. The iron would feel especially warm when it got to the point that I’d get bogged down. More importantly, if it makes sense, grinding felt “gummy” rather than “crunchy” or “gritty” as it usually does.

Lesson learned: None. I have no idea how to protect from this. I prefer to inspect the iron and guess whether its ever been flat and look for pits especially near the cap iron. I’ve not bought planes on eBay, only directly from sellers when I handled the plane, but when I looked on eBay I often felt the photos did not tell me enough. I did get a 151 spokeshave from eBay for 30 bucks and it was *beautiful.* A quick sharpen and it was ready.

4. Planes from old tool online vendors with long lists of tools. These vendors have been convenient but essentially none of the tools have worked out. These have been various hollows and rounds listed as “workers,” but when I looked at them, they were useless, e.g., twisted bodies, poor escapements or mouth openings, or not to the expected dimension. Maybe metal planes would be okay.

5. A *new* Stanley 71 router plane, i.e., recent manufacture. As Schwarz would say, a tool-shaped object. Useless. So much backlash combined with a fixing-nut that does not allow you to take up the backlash and move the iron, that the tool is useless even if you manage to sharpen it. Lesson learned- Just by the Veritas.

6. Every edge tool I’ve bought from Lee Valley (router, plow, narex chisels): Beautiful. Go right to high grits for polishing the backs. No need to flatten if Lee Valley says it comes flat.

7. Scrub plane- A lot of fun. Now it sits on the shelf because it is so narrow. Instead, get an extra #5 blade and put a heavy camber on it or dedicate a #5 to this. I use this a lot. You can hog off a lot of wood and it’s fun to pull up shavings (gouge-ings) that look like peanuts.

8. Saws- Because of wavy plates and cows and calves, these have been harder to learn to tune than planes, but I’m getting there. I wouldn’t really know what the goal is if I hadn’t had the experience of using saws sharpened by Paul and, even then, several saws each of which felt different. The feeling of having a correctly sharpened saw transition from gentle rubbing at the tip when starting to a definitive and defining bite with a single push as you lay down level onto your line or knife wall is hard to convey. Best I can say is that it’s like crunching potato chips. Sorry. I wish I knew how to get the waves out of the saw plate.

Sorry this is long- You asked for experience. Bottom line: If you are serious, you need to master your tool. Any of the paths will work but they all will take effort. Personally, I enjoyed the process. The limiting factor is confidence. I’m not sure confidence can come without experiencing doubt. Once you’ve had a good dose of doubt, see if you can work with a craftsman to either get unstuck or to see if there are things you’ve not been aware of, things you’ve not been sensitive to. Even with a tuned tool, I think you are going to spend time diagnosing cutting issues related to tricky grain and I think the insights from fettling the tools helped me with what little experience I have overcoming these grain issues.

To be clear / fair, I should add that the Hock blade did cut beautifully. I did not intend to sound too negative

Not to add to any confusion, but in hopes to clarify some details. When it comes to price it really depends on where in the world you live. Vintage tools will always cost less, that’s a fact. But, for instance something like the Lie Nielsen Bronze No. 4 , It costs $350 US dollars in the United States, but in England it cost $517 equivalent US dollars. That is a big difference. I am sure in other countries it could be even higher.

I bring this up, because when people talk of the cost of planes, we may not all be thinking of the same numbers.

If I lived in the UK I probably wouldn’t buy new either. Even when I bought my LN #4 , I bought it used off ebay for $80 US less than they sell for new, and that was a stretch for me.

This is also a good point. US and Canadian importing certainly jacks up the price. I suppose I might consider the UK Clifton planes if I was looking for a heavy plane maker. I know it’s a good plane and the cost is around £230 or $350 USD. I don’t think that there is much difference between LN and Clifton except Clifton has the hammer-forged cutting irons, which I think supports better edge retention (if indeed that’s still the case).

Another point not to be dismissed is the UK prices on eBay and on secondhand markets seems to be considerably less than the US and EU, shipping within the UK is a less than the US too and you can pretty much guarantee receiving your buy within 24 hours of payment. I can go to a carboot (fleamarket kinda sorta) on Saturday morning and pick up half a dozen #4’s for between £12-15. On eBay they started going up the more I blogged, but they can still be had for between £15-30 and 4/12’s not much higher and in great condition. I just checked and there are about 500 listed right now.

A very good point Bill, and there are indeed many good second hand #4’s on UK ebay at the moment, you prompted me to see what was out there and there are a few gems. So envious you can get LN’s craftsmanship for such a good price!

I know I am new to woodworking but I love old tools in general especially planes. I started out picking up old tools at flee markets and antique stores for something to do while I was recovering from a back injury. I fell in love with rebuilding and tuning them up. As my new hobby progressed I started to fall in love with the mere task of testing the planes. After watching your videos on tuning and practicing I was hooked. I love the ones that someone has engraved there initials on. This to me represents a fine tool that a craftsman has fallen in love with. I do not question anything you say you are the master, I am the student. Thank You for what you do.

I have two #6’s, two #4’s and several wooden planes. All have been either bought on ebay or I inherited from my Grandad who built Spitfire bases in World War 2. I have never had any problems tuning and sharpening and they have all become ‘dear friends’ after I found myself forming a bond with them while doing so. I honestly cant see the difficulty, even for an absolute beginner as I was, in following Paul’s instructions for tuning and sharpening and unless you are starting with a real ‘lemon’ you’ll end up with a very useable piece of history. I have used brand new planes by LN and Veritas and whilst I can appreciate the engineering I much prefer the feel and the idea of an old plane.

I have to say I am fairly new to woodworking and fell in to the “youtube school” of what tools I needed. I went out and spent a lot of money on some veritas planes. I got their bevel up jack and jointer plane. Both are nice planes but quite heavy. Shortly after I found Paul’s web page and started following him. His thoughts on planes were against the main stream but eventually I found a cheap stanley 4 1/2 on ebay and picked it up. I followed his methods of set up and sharpening and soon it was my favorite by far. I then picked up a No. 4 which quickly took over that spot.

My point is that I am one of those that is willing to spend the money to get good tools but in the end the best value by far were the stanley’s. The only time I reach for the others is for shooting end grain or jointing long boards. Each person should make their own choice but don’t let the job of truing up an old plane scare you off it really is quick and easy. For under $50 bucks you can’t go wrong.

One of the things I have learned as a fiddler is that one makes better music the less that you hold the bow. Similarly, by not choking the fingerboard (that fretless fretboard) you are better able to find notes and be more dexterous.

What has this to do with woodworking?

Well, I also own a few Clifton and Lie-Nielsen planes and so I scorned Stanley and Records after I found them. They are beautifully engineered, fantastic things. But I agree with a previous commenter: they have that bling factor.

Only once I found Paul’s blog and youtube clips and now that I am following his Masterclasses have I realised that the lightweight planes are the way to go, because they require so much less effort than the heavyweights and they work so much better for me. Like fingers around a bow, or on a fingerboard. The music is so much sweeter if it is allowed to flow effortlessly.

So now I never reach for my heavyweights, once the pride of my collection. Also, since I have rediscovered the lightweights, I have more fun working wood.

So thanks, Paul. I am glad to have found you, your blog, and your Masterclasses.

I was in Penrhyn on Saturday evening, having a look at the harbour. I am now considering doing a course with you, berthing the boat there as accommodation for the duration of the course. So if not this year, then next.

🙂

I’d make it this year. Then you can show me your boat!

haha, it would be a pleasure! some lovely craft there, also a boatbuilder!

I bought all my older planes off eBay. While old, most were hardly used with one or two appearing to have never been used. They were certainly not tuned up. One had been used a lot. It was taken care of and had been tuned up properly. It’s a Millers Falls #18 which is like the Stanley #6. It has always felt better in use than my other planes. Lately I’ve been retuning my planes finding I am doing a better job now than I first did. I am using the original irons which I had replaced with new, thicker blades. The better I get at tuning them, the better they perform.

as a 26 year old woodworker just starting out, I’m ashamed to say I find myself buying new.

It’s not vanity that discourages me from second hand – if anything I’m quite tight fisted, as well as mawkish about the history invested in a tool. But I think it’s because I’m at the start of my WW journey that I want my plane to grow with me.

I think you’ve said before, paul, that your stanley was a week’s wages at the start of your woodworking journey and it’s still with you to this day; and one day will (presumably) be Joseph’s plane. I hope one day my shiney new plane will make my son a wonderful loved and patina’d plane, and he can remember me by it.

Ben, the sentiments that you show are far advanced compared to mine at your age and something of a credit to you. I purchased my Record smoother when I was about 19 or 20 and though not the most refined it has been my daily onsite workhorse for 20 years and it has that slight softening that only comes with use, time and refinement . I have my fathers Stanley smoother next to refurbish and fettle – he was not kind to it but I know what he did achieve with it for his family along with his other tools and that counts as much as a plane that has the careful considered hand of a fine craftsman on its surface. I too would like to pass on to my son my tools with the weathering of use from my hands, maybe from others as well as the Grandfathers he never had a chance to know.

I am sure he will. I bought my boys their tools as the grew old enough to use them. I also but tools for them when I am gone. I set them aside and make certain they are in prime condition. When I go I will have used them alongside my own to make certain the feel good. The boxes i have made through the years with them in mind will have their names on them. And then I will start on my grandchildren’s tools and boxes. If there is time.

Paul,

I agree with you that when buying a vintage used plane you are buying into an honorable history and by using it you are honoring and becoming part of it’s continuum, BUT what about being the one to start the continuum?

Like most I have a mix of old and new tools. I love the thought that some of my tools go back to the early 20th (or even late 19th) century and in many cases were used by relatives of mine that I never had the chance to know.

On the other hand, when suitable used tools aren’t available or when I have some extra money (or sometimes as gifts) I get pleasure from picking up well made new tools from fine makers like Lie-Nielsen and Lee Valley. There are the obvious functional advantages of buying a well made tool new, but I also gain satisfaction from STARTING the tool on it’s journey, a journey which (hopefully like some of the things I am making) will likely be longer than mine.

Nothing is certain, but the thought that in the year 2100 or later my Lee Valley block plane and my Lie-Nielsen dovetail saw should still be working and might even be in the hands of some distant relative who needed tools to get started with a new hobby (as I did) is very satisfying. More immediately I have great tools to use that needed little setup and I have contributed to companies which are carrying on a different tradition of making great tools.

Just my two cents worth. Thanks for all your videos and writings!

A thing to consider about buying new or used hand tools is that the cost of good hand tools way back when was a major investment and set a woodworker back a few (many?) weeks salary. So it is with new tools today. I bet that the woodworkers back then were having the same discussing as we’re having now.

My first plane, #4 Stanley, cost me a week’s apprentice wage which was £3.50. There was zero tolerance for borrowing tools or even looking into someone else’s tool chest from within 2 metres away, so you better get tools quick or end up sweeping the floor and bagging shavings all day.

I have just a few hand planes right now. I love them though. The only one I bought brand new was my #4. It’s a Stanley that I bought at one of the big box stores. The plastic tote on it just came apart in my hand and now I’m fiddling around with trying to get it’s replacement fit right. Yet my #5 that is probably 40 years old and isn’t the greatest is doing just fine and my #7 which is a Type 11 is actually in great shape and is wonderful to work with.

The only class I have taken so far was a Hand Plane tuning class. It may have been the best $75 I have spent on wood working so far.

I will continue to shop for used/vintage planes whenever I decide I need another. But then I really enjoy the process of tuning them up.

All the best

Jim

I have picked up a few Sargent hand planes lately. A Jack I picked up at an antique store and a lot of three from ebay which included a rabbet plane without the depth stop and a chunk broken off the sole, a smoothing plane with a broken tote and the prize a transitional 3410 in very nice condition.

The first plane I ever bought was a Stanley sold at my local Lowes, about 2 years ago. Chinese made, and literally a piece of junk next to my Dad’s 1930a #5 that is my go to now.

But it was all I could afford. I took that cheap chinese Stanley, and because I did some research online before I bought I understood that the sole would not be flat, and that I would have to do a lot of work setting the plane up before I could use it.

So I took the plane apart, followed a tutorial online , flattened the sole and set it up to within an inch of it’s life. I used that plane for over a year, and it did everything I asked it to.

Then, while roaming around a flea market, I found an old Millers Fall equivelent to the Stanley #5. Followed the same procedure, and had it up and running in no time. Much better.

Then, my father passed away, and I inherited his Stanley #5. Lovely plane. It will be with me until I die, hopefully with my fingers still curled around it.

That old chinese Stanley? Well, I took it apart, glued some sandpaper to it’s sole, and use it to level frets in another hobby of mine. Building musical instruments.

I said all of that basically to say that pretty much any plane that you can get sharp, get the sole level, and set up well, will do the job. But there is something about quality that you can feel the moment you hold it in your hand, and the old Stanleys epitomize that.

I’m scouring flea markets now for old tools of all kinds. Chisels, saws, rasps, anything good quality that I can take, do a bit of work to, and use them to do things like make wood sing.

There’s nothing quite like a good, well made and cared for old tool. Somebody loved it before I did. There’s a reason for that.

I did a 5 year carpentry and joinery apprenticeship in the early 60’s and we only used hand tools. When the 80’s came so the screeching power tools came and you had to wear eye protection, ear protection hand protection and head protection. I found no pleasure at all. I could not see because the safety glasses steamed up; I could not hear the birds or what people were saying about me behind my back because of the ear protection! I lost my sense of touch due to the gloves etc Hand tools are an extension of your body and all the senses, in my opinion,are required. Now that I have retired I found all my old tools, I always carried them with me from house to house, over the years but not used them I found my old Disston cross cut saw not used for 30 years but still cuts, as did my tenon saw. What was remarkable I found my wooden moulding planes which I used to copy Victorian skirting boards, when hotels were being renovated. I put a piece of wood in a vice, picked up the plane, just as it was and it took a shaving its first shaving since 1965. 50 years and still ready for work. All the tools are eager for work, its just me letting them down because I am so out of practice.

It’s not too late, James. Go for it.