Cheapo Planes and Saws – Are They Worth Effort?

Question:

Hello Paul,

I have noticed a number of shops selling hand planes for ridiculous prices. Machine Mart has own brand Clark’s on offer for less than £20 for a no5 and less than £12 for a no4. Would you ever consider trying one of these low price planes and seeing if you can get it to sing like one of your old Stanley or Sorby planes? I guess with some tinkering they may be adequate.

On another note, I have quite a collection of plastic handled saws that I have been collecting of various makes and types. Would you ever consider manufacturing your own replacement handles for these? Would it matter if the teeth are hardened? Could I file them off and start from scratch?

I’m currently attempting to make your workbench using some old 3″x9″ timbers we reclaimed from an old cowshed in Dumfries. I’m trying to do it all by hand and resisting the urge to stick it through the table saw. I’m just finishing up on the first length and have burnt a few calories I can tell you!

Thanks for being an inspiration and keep up the great work.

Kind regards

Stef in Hull.

Answer Q1: Are import planes worth tinkering with for good results?

Answer Q2: Are plastic handled saws worth replacing the handles on?

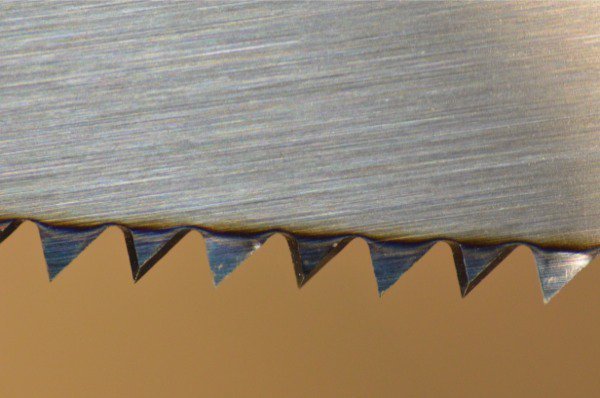

There are a few old plastic handles from the pre-hardened era like this old Sandvik from the 1960-70s era. I used one of these for 40 years and still have it. I own a couple I have picked up and plan to put wooden handles on them. They were made from good swedish steel.

Answer Q3: Using machines – Do they have their place?

This wasn’t really posed as a question but offered more as a workout instead of the gym. But the question for me is am I cheating if I use a machine. My answer is that it depends on many factors not the least of which is whether your goal is to develop the substantive skills or substitute for it. Everything I do is to resolve the desire in people to become truly competent in their use of hand tools and to discover just how valuable they really are.

I have no problem using machines and indeed anyone else using machines. Much of what I do is to show how non-essential they are if you don’t have them. Remember that 95% of British woodworkers do not have power equipment nor the space to keep it and use it. I found that in the US on the other hand, people had massive space and land even to build a dedicated machine shop for woodworking. When I asked a class of 20 students in the US who had a machine set up with five or more key machines, 80% raised their hand. In the UK when I do the same almost every time no hands go up.

Thanks for these questions. I am sure others have the same questions and so I hope that this answers their questions too.

Paul,

I was given a faithful #4 plane, it was not in very good condition, but I had a go at restoring it, now it works just as good as one of my Stanley’s/Records, its a little bit heavy but works a very well, This was not the sort of plane I would have considered to buy, but I was impressed by its performance. what are your thoughts on faithful planes. But you are right about eBay you can get some great old planes at a decent prices, I have just bid and won a record jack plane for £18.00 +£4p&p, it will need a bit of loving care, but that’s the fun of it.

For some of us , living in different corners of the world, these types of cheap tools are the only ones we can access, due to low cost of products and low cost of shipping used by the profile sites.

For example a Disston saw (ebay.co.uk) you pay 20 USD (decent price ) but you need to add 40 USD for shipping .That makes the offer to high for my budget.

I bought the Faithfull No3&No4 and I am pleased with the result , they are working very good I would say.

I also bought Faithfull No10 and I was very disappoint ,all Paul’s comments apply.

Thanks for your very informative response. I was particularly interested in the use of power tools section. Initially upon embarking on this quest to learn a craft, I became temporarily blinded by the many videos on YouTube, and of course those that Norm produced. These all promoted the use of power tools, which I could never have the room for or even be able to afford in many cases. It was then I discovered your existence, and decided to follow a different route to woodworking, not wood machining. So thanks for that. Most of my machines are currently consigned to a dark area of my shed now. Laying silent is the compound mitre saw, as is the jigsaw, bandsaw and scrollsaw I managed to inherit. The ambition I had to fully restore an old dewalt radial arm saw i got for free has now gone. Now I look forward to learning a craft where time, finesse and “little by little” are the key to quality, and as many classic hand tools from Sheffield I can lay my hands on. I think I’ll still use my ancient Multico table saw, after all it’s a perfectly flat surface, makes a great workbench until I finish your design, and can dimension timber. Getting rid of bow and twist by hand will still burn those excess calories from all those mixed grills at the local Wetherspoons.

Any tips on what to look for in used saws on EBay? Before you snap them all up that is.

Thanks again

Stef (in sunny Hull)

The saw tooth question would seem to be more of a ‘metal’ question than a woodworking question. The metalworking shop people talk about detempering, retempering, and hardening tools.

I do -not- know if it’s possible. But it does sound at least -plausible- to “fix” a cheap impact-hardened saw. (There’s no way it will be simpler, and I don’t think it will even end up cheaper than starting with a better saw in the first place.)

I’d point at somewhere like http://madmodder.net/ as somewhere to start searching. The metal lathe/mill folk discuss ‘hardening’ things often–because it’s mighty tough to be -cutting- things that are already hardened, easier to do the hardening last if you can.

I came by hooked on “just making a box” for machine tools, and have greatly enjoyed reading and watching the skill and knowledge on display here. Thank you.

Paul, Thanks for this post. I was wondering the same thing while at Lowes this past weekend. I picked up their store brand No. 4 Plane and thought that it felt heavy and the casting looked fairly thick. I wondered if it would be worth paying 30.00 for. But I thought, unless someone who knows more than me says it’s a deal, I’d best pay a little more for a known good item like a Stanley or Record.

As it happens there is a guy within a few miles of my house that has a sketchy looking garage full of stuff and a bright “Open” sign in his window. I stopped in and met a very nice and talkative man with a bunch of interesting old stuff for sale including a No.4 Stanley and a No. 35 Stanley. I picked them both up for 85.00 U.S.. I bought the No. 35 because I liked the way it looks.

Travelling through a small town near me, I came across a junk shop and decided to take a look. I found an old Disston that was straight – no bends, or kinks – but the handle is broken off such that it looks like a gents saw handle. I don’t care. The steel is good, and it dates between 1896 – 1917 which makes me happy to have found an oldie but goodie. Some day I may be good enough to sharpen it and maybe even fix the handle. I paid 5.00 for it. The only reason I bought it was that the medallion read Disston and the handle has a little bit of the lambs tongue left. The lambs tongue told me it was pretty old and Disston is a good brand.

I have found Warran and Ted Superior saws for around 2.00-5.00 at flea markets. I bought them even with kinks for practice sharpening, and maybe even learning how to hammer the kinks out. If I can’t fix the kinks, I can always cut them down.

So for those looking to pick up tools, hit the local flea markets (Paul calls them “Boot Sales”), farmers markets, church sales, heck, even local thrift shops and second hand stores. Ask if they get old tools.

As to what to look for in saws, teeth can be fixed a lot easier than a kink I think, so try to find saws that are straight. Look for smooth and carved handles. Once you see the difference between the clunky blocky handles like on the current Stanleys at the home stores, and the craftsman made carved and curvy saw handles from the 1900’s you’ll be set to find some gems.

Almost forgot, look around your area for a sharpening service guy. I paid 7.00 for a somewhat old (post 1955) Disston (HK Porter) that a guy never came back for. It’s beat and has stamped/burned in wheat on the handle rather than carved in, but still it cuts nicer than I can saw.

I know I got a tremendous deal — a steal, really — but I just bought a rusty yet fully functional and restorable Stanley No. 5 jack plane for, you won’t believe it, US$1.99 off eBay. With shipping to Canada, it was under $20. So there is no reason to buy crappy tools. Great tools are out there for good bargains if you look. My latest plane, which came in the mail yesterday, is sitting here beside me now in all it’s rusty glory just waiting for the weekend so I can clean it up and listen to all its stories. So excited!

Gord Clark, Vancouver

1.99, you did better than I, mine was 50 to the door or so for a type 11.

I grew up in the age of Norm Abrams yankee workshop tv show, I was about 15 or 16 and just knew I could build wooden works of art if I only had tools just like him. Nothing against Norm, he inspired a lot of people to start a journey into woodworking. In my early thirties I built myself an 800sqft shop and filled it with some of those wonderful power tools and I was happy. That is until a man named Paul Sellers and others like him introduced me to the idea that woodworking and hand tools really went hand in hand. Thanks a lot PAUL, for ruining my ignorant happy dream!

I got to a point in my woodworking where something was missing, I wanted to improve, take my work to the next level. I wanted precision, crisp cuts, solid and beautiful joinery, something I was not getting from the power tools. Don’t get me wrong, I will never give up my 3hp 10″ cabinet unisaw table saw or my 13″ planer or my lathe etc. etc. I am finding however that I am using most of my power tools less and less. The quality in my projects has gotten better and I thoroughly enjoy the journey and process of using the types of tools that have been used for hundreds of years. So once again I say thank you to all of you at the Paul Sellers woodworking schools and to let you know you do make a difference.