Coping and the Costs of Coping Saws and Blades

For more information on saws, see our beginner site Common Woodworking.

I have always wondered why it seems more and more that we have adverse concepts about standard coping saws when they are so efficient and effective in use and they are one of the easiest and lightest of saws to use. I have given my now five adult sons a coping saw to work with from being about three years old with never an issue of workability and they shaped and cut everything from cutting boards, spoons and spatulas to cello, violin and guitar parts for about 25 years or so without issue. Compared to other saws they cost almost nothing, with new ones like the Bahco or Eclipse costing somewhere around £10-20 new and even less secondhand. That’s so little for a saw tool that could not wear out in a lifetime of full time use.

In more recent months I became intrigued by some developments that took my interest more through the comments people made and were making than the concepts of coping saws themselves. It seemed that suddenly, once again after a century or more of use, that coping saws didn’t really work. That’s according to recent comments.( I suppose perhaps they were ignorant workmen who knew no different.) One person says that most coping saws don’t tension the blade sufficiently and therefor the blade feels as “floppy as a steel hotdog.” This type of statement inevitably paves the way to promote something else rather than the truth. It’s far from true unless you buying something low-grade. Another source says that the saw weighs only two-thirds the weight of a regular frame saw and that means less fatigue on the body if you use it all day. Two things to consider here. One, do you plan or even consider that you might use a small frame saw like a coping saw or a jewellers saw all day and, two, we are talking the difference between 8 ounces and 12 ounces or 226 grams and 340 grams respectively. Roughly the weight of say a small- to medium-weight chisel so I think it’s OK to have a little weight to add balance to a saw like this, especially when it’s so light weight to start with.

In both cases here the saw they want to promote costs a massive £120 (or $180 USD) to any UK buyers. Now that’s a chunk of change and so I asked myself whether this choice came from common sense. Yes, if you want to, go ahead and spend the money on a high end saw, but to dis what’s been around for centuries (and the hundreds of thousands of craftsmen that used them too) and put heavy priced burdens on those looking to make an educated purchase seems inappropriate but more and more common. My suggestion is to let common sense prevail and carefully weigh everything in the balance. Ordinary coping saws work really, really well and are just great for even discerning craftsmen.

I’m in my 50th year of using an Eclipse coping saw most every day of those 50years. About 15,000 times. I suppose some might justify paying a high price for a tool that comes with better engineering and so on, or just that the price is immaterial, but to most people price can be and is of course prohibitive and any influential leader can indeed mislead people to believe one tool doesn’t work or work well. Perhaps there is some reason they have to dissuade people from buying something that has worked perfectly well for a century for hundreds of thousands of woodworkers and metal workers.

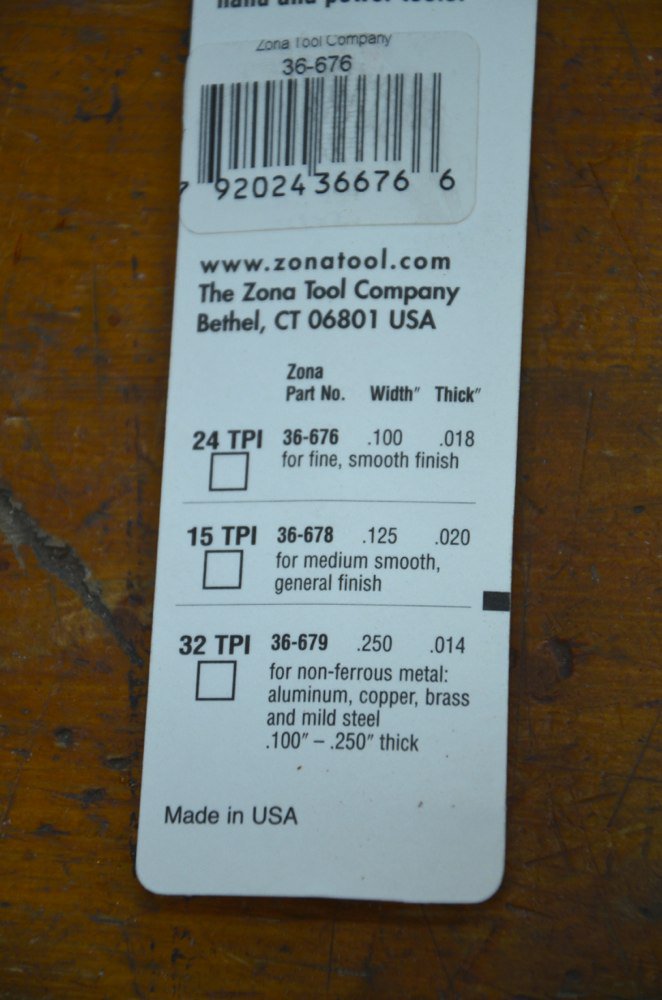

The Bahco coping saw is an excellent make of saw that’s got good spring steel for the frame and takes the 6 1/2″ blade common to all coping saws. The Zona blade fits all 6 1/2″ coping saws.

I have been searching for good coping saw blades since the demise of the older Craftsman make blades I had used for almost three decades. This has now been resolved for me with the Zona coping saw blades. Even though made in the USA the price with shipping is not prohibitive at all for those of us in Europe and the UK. I bought 40 blades for £21 ($33USD) inclusive of shipping and ordered on the 2nd November and received them at my door in the UK on the 8th November. I got blades I wanted not what was available and was as impressed by the quality of cut I got from the blade as I was with the four-day delivery with door to door of 4,500miles.

Someone else wrote that the general coping saw buckles under pressure, but, once again, I have never found that to be the case at all if you buy a halfway decent maker such as Bahco or Eclipse. I doubt anyone could cause a saw to do that but I wanted to prove my case for those searching for a coping saw.

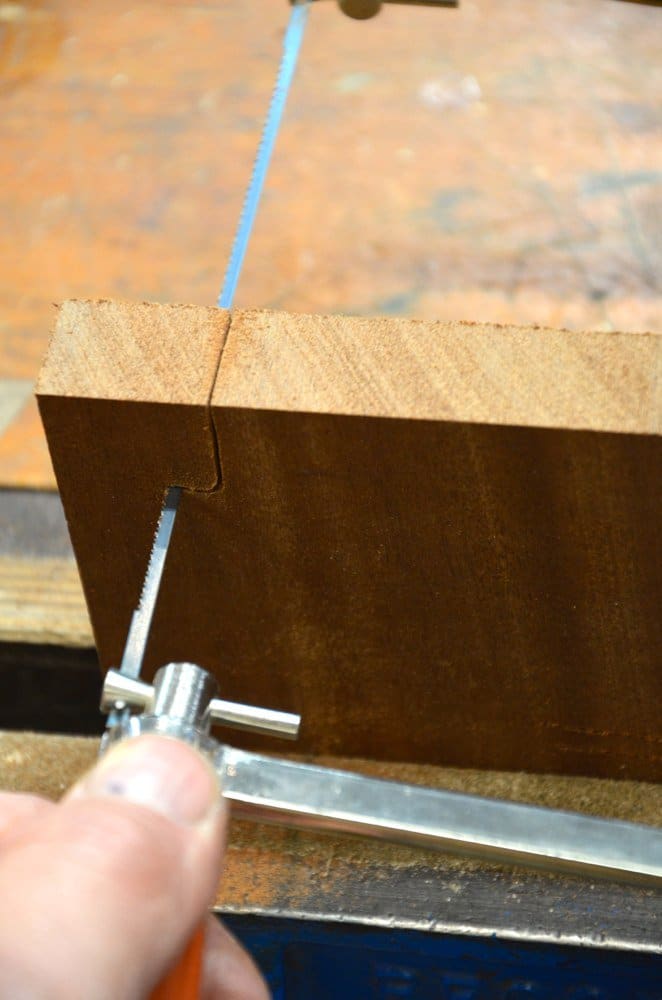

I installed one of the new Zona blades and cut through some thin 6mm (1/4”) thick sapele stock. The blade sliced easily and very smoothly into and though the wood with the extra fine 24 TPI blade installed in both Bahco and Eclipse coping saw frames.

I then cut through some tight shapes with the same blade and used 21mm (13/16”) sapele and got exactly the same results as I did with stock 1/3rd the thickness.

Here I upped the ante and used the same blade to cut the straight and tightly curved shape you see from 68mm (1 3/4”) oak with no buckling at all and with a very satisfactory speed all the way.

So, all in all, you don’t need to spend big bucks on a frame saw unless you want to. Buy good blades from Zona, very inexpensive in the USA, who have 15, 24 and 32 TPI. You won’t be disappointed.

There is no issue for smooth and effective cuts with a common coping saw as long as you have good blades.

Thank you for your good information, Paul.

I’ll just second this sentiment, and add that these kinds of posts are almost literally worth gold to us beginners who struggle to separate out good information from bad. There’s always someone ready to try and sell us stuff…

Hi Paul,

It’s just another example of the so-called “experts” recommending a “must-have” tool that is completely unaffordable to the majority of craftsmen. I also saw a recent endorsement for a mallet that costs over $200 US. And I would be willing to bet that it doesn’t work a bit better than my inexpensive Thorex chisel hammer. Thanks for the info. I have a Zona “Gent’s Saw” that I’m quite fond of, but I was unaware that they made coping saw blades. I’ll give them a try. Enjoy your weekend!

I’ve been using an Eclipse coping saw for many years, and always been satisfied with it. As you say, the blade used is what counts. Up until recently I’ve been using Eclipse blades, but following a post by Chris Schwartz, I’ve bought some Pegas 18tpi skip blades to try. Never heard of Zona, I must give them a go. What is wrong with Eclipse? Have they gone the way of the Chinese?

Funnily enough, my four year old lad and I were cutting our first dovetails together the other day with a coping saw, he enjoyed it so much that I have bought him one for this Christmas. He often asks if I can put ‘Woodworking’ on the computer so he can watch and learn from Mr Sellers.

Paul thanks again for bringing your many years of experience and knowledge of the tool needed, ( and not needed ) to us. Most mags, books, podcasts, youtube ect make it look as if this craft, or hobby for most of us is only for the wealthy. You teach us what we can do with affordable tools, and even a small toolset. I would rather pay for knowledge than have an expensive tool set and not know how to use them. Also thank you for clearing up on volume 3, I had really been looking forward to it, I’m glad to hear you will be doing more with books and dvd also.

I remember reading this all a while back and began to think my Bahco one will never be able to work well. It’s always worked fine for me so I didn’t understand what people were complaining about. When I tried tight radius on dovetail waste I never found decent blades here in Australia that could turn so tightly so I gave up looking. Was sick of wasting money on different blades just to try them out. Thanks Paul. I’ll try to get some Zona sent over now. I’m glad you addressed this. I must admit I did nearly consider buying one of those over priced fret saws a while back. So glad I didn’t. I’ve been ripped off by Salesmen more than enough for one woodworkers lifetime. We all have to cope with the decisions we make. Paul makes it easier. Thanks.

I have been a trim carpenter in the US for 25 years and use coping saws daily to install trim in new residential construction.

I have found that most new coping saws dont cost more than $10 and the blades are reasonable to purchase in packs of 10 .

My joy is in finding and using older vintage coping saws and find them at the same reasonable prices.

The biggest difference I find whether old or new is the end of the handle shape and how it effects the handling and comfort when I need to do lots of cope cuts in a day of cutting and installing base board for example.

the handles with more rounded ends tend to be the most comfortable since some of the cuts I find myself presseing in with the palm of the hand to make saw strokes etc/

SO I expect that some folks impressions of coping saws being good tools or not might be due to comfort of use whether it cuts well or not.

My advise is if not the right fit make your own handle so it works comfortably especially if you makes lots and lots of cuts per day like I do.

Best Regards

Hi Mr. Sellers,

Do you have any method of gauging the proper tension in a coping saw blade? The one I have feels a bit on the loose side, even with the handle tightened fully. I don’t have enough experience with coping saws to tell the correct tension. Do you prefer the blade be as taut as possible, or something else? My coping saw is a nameless one, and my blades are Craftsman labeled Made In USA. Thanks for all your help.

This sounds like a non-starter to me. Coping saws are tightened all the way and the blade pings like a guitar E string. The frame should be taut and pull the blade as you tighten the handle to maximum turns where it stops turning any more.

I used to think to tighten the blade you turned the handle! Then I saw Paul load a blade by compressing the frame on his bench. So simple but I never received instructions on this. Thanks again Paul. I bet I am not the only one. Could be the reason behind those new fancy coping saws as the blade tensioning uses a fancy clip. Paul feel free to correct me if I am wrong.

I actually loosen the handle some too, but instead of going all the way which is not usually necessary, I do lean into the bench to compress the frame and insert or take out the blade. Pretty good observations there.

Hello Paul.

I must admit to being one of those who finds it difficult to tension my Eclipse saw, or perhaps its the blade, which binds and makes sawing straight difficult. Paul, already with the knife walls you have improved my woodworking, I hope and pray you have a suggestion here!

What blades are you using? Eclipse coping saws work exceptionally well, so I might first question the blades, eclipse blades are junk. Most Sears USA blades are junk but the one blade they did sell at one time was exceptional. I would then go to your particular saw and check that one alone, which may just be one bad one. The garbage some of the gurus come out with to denounce one tool to sensationalise another newer one is just smart-alecky silly in my view. I never came across a decent make that didn’t work well. Old coping saws are almost all good.

paul,

They are Eclipse blades, so I will try zona one.

Chris from Belgium

For most of us, it’s far easier to feel superior with what tools or materials we buy than to develop the skills and expertise. I see this in hand tools, power tools, photographic equipment, you name it… Many crafts have been practiced with no access to super expensive tools by people all over the world. That is enough to convince me to do the right thing – spend time acquiring the skills.

I’m glad you’ve done a blog on this and you mentioned Zona blades, I was lucky enough to find them in Australia and just bought some. I don’t like the blades that come with the saws. I currently two saws the other has a large throat German brand I bought from lee valley, the blades I got are very thin for intricate curve, unfortunately they flex too much in the cut . I do have it set for the right tension if you were wondering still though it is a very good saw.

As you may know, I use the coping saws on the push or forward stroke and yet even then they never buckle unless I am brutish. So, that for me means they never buckle. I have had blades buckle on odd occasions but not because of me but because of the make. If the saw buckles on the pull stroke set up then it is buckling on the return stroke on the reverse side f the blade and so this is a body/arm alignment issue and incorrect posture usually.

I’m fine coping miters for trim, but as the material becomes thicker, I have trouble with the back side of the blade not being where I expect it to be. So, I follow a layout line on one side of the work, and the back side wanders from what I want. I’ve always had the Stanley blades, because they were available. Oh, also, in thicker material, the cut can be very very slow. I’ve always assumed this problem was from the blade or my skill, but not the saw itself. How can the frame matter as long as it holds the blade?

The Zona blade sliced through the oak on rip- and crosscut strokes like a knife through butter and with no tripping and as you can see from the ‘boot’ shape in 1 3/4″ stock it came out square and parallel. The more you do the more confident the cut.

Paul a great topic, I have a newer Eclipse which works well. However I have used “Olson Blades” which are decent but most recently been using Pegas Blades which I really like. I have not heard of the Zona Blades either.

Steve

I can’t find the Zona blades on eBay. Must have sold out after this post. Typical! Oh well. Guess I’ll add them to the list of things to search for in future when I have more time. Where did you find them Salko? Bunnings?

Hi. If you do a search for Zona Tools, Bethel, CT, you can order factory direct.

It seems that Zona bought Olson, or vice versa. The URL even shows Olsonsaw not Zona like it used to. When I went to the “Zona” website looking for coping saw blades, based on the pictures, they were selling Olson blades not Zona. I would call before ordering.

For those of you residing in Australia you can purchase these blades from http://www.hobbytools.com.au/ $12.40 for a pack which contains 4 blades.

Thanks Salko, I already put some on back order through omnimodels/eBay last week. The site will probably come in handy in future though so thanks for that, they seem to sell a lot of woodworking tools. What size coping blades have you tried? I think I ordered 24tpi and 32 tpi. Will see how they go. I want to get a tight turning circle when clearing dovetail waste but not too fine or they take longer to cut. .Hopefully they will be Zona as pictured. I asked them about the Zona blades now being sold by Olson with the take over but they said they hadn’t heard anything about Olson merging with Zona so I don’t know whats going on. They are expecting the new batch of Zona blades any day now. Even with the cost of postage to Australia it still works out a pretty good deal I think. Will find out when they put the order through, maybe I shouldn’t talk too soon.

The coping saw blade market in the U.S. confuses me 😛 . I don’t bring this up to contradict anyone, honest. I just want to put it out there and see if anyone has input. The Stanley blades at Home Depot, the Craftsman ones at Sears, the Olson blades and the house-brand ones at ACE Hardware, the weird Excel brand at Dick Blick’s Art Store, the Zona blades, they are all (surprisingly) labeled Made in the USA. Can’t be 100% sure obviously but I suspect they are all made under the same roof (Olson). There can’t be as many coping saw mfgs. left in the U.S.(?) Opinions?

I agree it’s confusing and difficult these days to truly know where tools are made as many ‘known’ makers use their brand name and lease their name to other companies. Spear and Jackson for instance allows Argos to have goods made for Argos and put the S&J brand name on the goods yet S&J had nothing to do with the the product at all.

Hey Salko, I just received this email from omnimodels notifying my order for Zona blades is on its way. $2.89 for a pack of 4 plus .90 shipping! All the way from the USA!

Not a bad deal really. I can’t believe how cheap the international shipping is. If they are charging $12.40 for a pack locally then I think we are being ripped off (as usual) here in Australia. That’s a big markup for the exact same product. The other ones I ordered are on back order but even if I have to pay shipping twice I don’t mind at that price.

Not that I’m gonna need large quantities or anything but it’s still interesting to see the variation in prices.

The following shipped from Champaign, Illinois:

Stock Number Quantity Extended Price

Product Description

ZONR3079 1 $ 2.89

36-679 COPING SAW BLADE .250(4

The following are out of stock and remain on your OmniModels customer account as back orders:

ZONR3076 6 $

36-676 COPING SAW BLD .110 (4)

ORDER SHIPMENT SUMMARY

Shipped Product Subtotal: $ 2.89

INTL SMALL PACKET AIR: $ .90

Total Current Charges: $ 3.79

The majority of craftsmen don’t run thousands of feet of crown either. Last year in one house alone I ran just under 1500 linear feet of 6″ knotty alder stain grade crown. My bahco was strained to say the least!

I for one am counting the days to order a brand new knew concepts saw.

Blackstone Industries LLC has bought Olson Saws, Zona Tools, Foredom Electric, and Edgefinisher. I think all of these companies are (were) located in Bethel CT USA.

Thank you Paul. I am buying hand tools and trying to make smart decisions. Since this is all new to me, I don’t know a good tool from a poor tool. I had seen the same disparaging remarks on coping saws and though I needed to spend $180 for one to get one that worked. I am glad that I found you on the internet a few months ago. From my perspective, it’s hard to beat the opinion of someone who has been doing this for 50 years. You aren’t affiliated with a particular tool maker so I like that I feel as if I am getting honest information.

Woodworks Craft Supplies here in the UK at http://www.ktoys.co.uk are selling Zona coping saw blades at £4.00 for a dozen with all tpi choices available

I don’t know them, but have bunged an order in and see that they have a banner or their site saying closing down sale…. I will let you know what turns up

Shipwright Rob

Well what turned up was Olson labelled blades… having tried neither Olson or Zona blades before I am in no position to say that one would be better than the other. What I received work well for me 🙂

Happy New Year all!

Shipwright Rob

I have always had problems with my coping saw. It is a used saw, and says “10 Disston” on it. There is a wing-like piece of hardware at either end, and neither will stay tight; they swing during the cut and twist the blade as they swing. Is it the saw, or is it me? Until now, I assumed it must be me, because Disston is supposed to be a good name in saws, but having read this, perhaps I should just buy a Bahco 30, or, if I can find it, an Eclipse – after all, it is not much money and I was thinking I might have to buy a KC! I looked for Zona blades, and can find just two sizes, 24 and 32 tpi. Are these too fine for 1″ – 2″ thick hardwood? I can’t find a Zona 15 tpi without paying more for shipping it 200 miles ($7.95) than I pay for the 4 blades ($1.41). Something in me won’t allow me to do that…

why are you coping 2″thick wood?

To disprove what others are saying about coping saws and try to convince you that a fret saw is better.

I can’t edit, so I’ll just correct a couple of words in my response.

…saying about coping saws WHILE TRYING to convince you…

Hi, another amateur here! Thx u Paul for the advice and to all comments. I though KC are fret saw but this article is about coping saws, I though there was a difference specially if cutting thin metal but perhaps some body can explain please.

Well – it seems the coping saw market is in decline. Most links above don’t work anymore, and if I go to th source (zonatool.net) I see Olson blades that set met back $45 for P&P alone (to the NL).

So where do I go for a half decent set of coping saw blades? Anyone?

Also on a side note, I bought a bahco 301 some months ago and the slots that receive the saw blade don’t line up so the saw is always bent. Unless I work the blade a bit with a hammer so it’s bent to compensate when I place it in the saw.

That’s it for me buying new tools online, I mostly get crap like this.. problem is, Coping saws are a UK thing I think, you don’t find old ones in car boot sales over here in the NL..

Mic

Just go for an Eclipse as far as a frame goes, and then Pegas coping saw blades work OK amd you can get them from Deiter Schmidt here.

I just took a look at the Zona Website (https://www.zonatool.net/) and there the shipping costs from the USA to Austria (and many other countries in the EU) is 45$ right now (Dec. 2017).

So I am looking at Dieter Schmidt and the coping saw blades from Pegas (https://www.feinewerkzeuge.de/dekupiersaege.html)

I watched a video recently on YouTube about cutting dovetails, and when the person got to the point where they were going to cut the waste out, they said something like; using your fret saw, cut out the waste… I just performed a minor cosmetic reconditioning on a Wizard 4 H 6339 K coping saw that I’m sure has been used a lot during its life. I don’t know where it came from, I know I didn’t buy it, but it was in one of those small gray Craftsman tool boxes that I know is mine because the other tools in it definitely belong to me. I have been using it occasionally for the past six years and it has performed flawlessly for me. It had a little bit of surface imperfections and rust, but after the reconditioning, it now looks as good as it cuts, so I don’t see any need to buy a another saw, let alone a more expensive one. Not that I was thinking of getting a new one before it was reconditioned.

These people on YouTube that make you think you need a $100 plus saw to do what a coping saw has been doing for as long as it’s been in existence must be getting some kind of commission when someone buys one through the link on their YT page. I am reminded of the old saying; “Build a better mouse trap, and the world will beat a path to your door.” Well someone tried to build a better mousetrap, but it seems all they did was to build a fancier more expensive mousetrap.