Update on My New Book

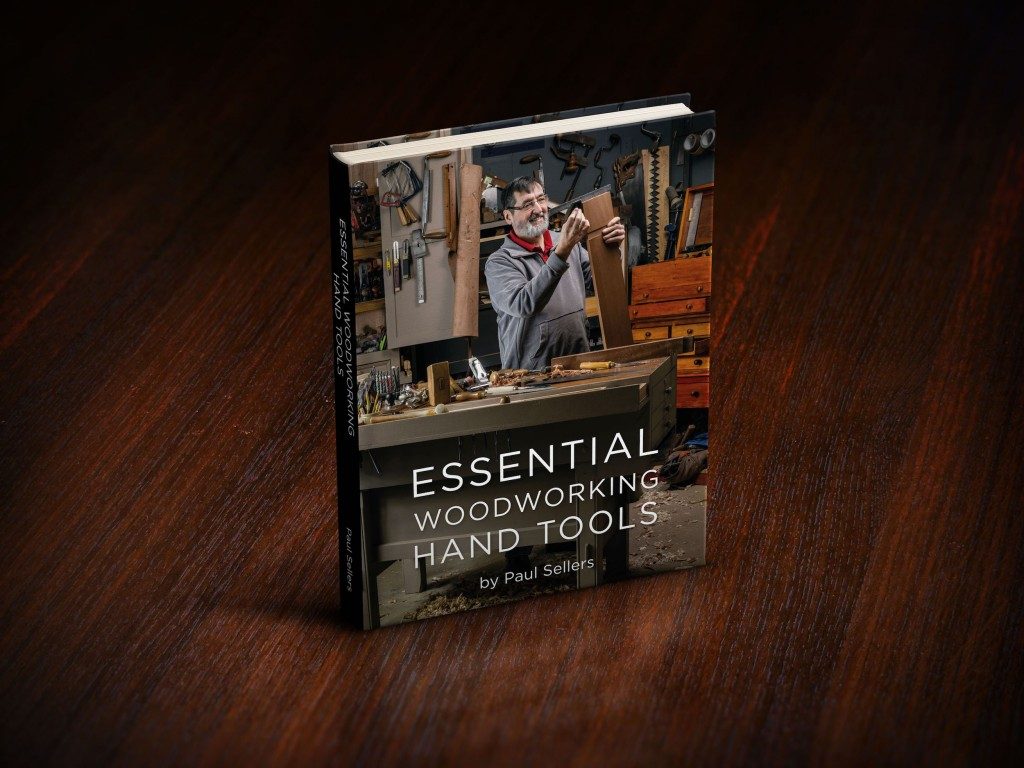

It’s the close of the year and many of you have faithfully asked about my new book Essential Woodworking Hand Tools. In these closing weeks I did what I do in finishing off my furniture pieces just before delivery. I leave the piece to stand a day or a week (depending on the piece) and then make sure that nothing has been missed or a change in the wood didn’t bump something out of sync. Joseph and I have been making the final adjustments and these often have a knock-on effect that then needs tweaking, but finally we have a book we feel proud to bring out.

It will be Smith-sewn, cloth-backed, hard-backed and printed ethically from ethically sourced materials here in the UK. This all meant that we missed our deadline and our place in the print queue and so we anticipate the book will be available sometime in February. The printers are shipping directly to our distributors in the USA so no worries for my woodworking friends there. The UK will handle the rest of the world directly. If you have not left your email address to receive the updates you can do so here to make sure you hear as soon as we have news that the book is available.

Congratulations Mr. Seller! I’m looking forward to your book, your techniques and tips have help simplify and inspire my woodworking.

The book is now listed at Amazon and you can add it to your wish lists and sign up for notification there as well. I know I’ll be ordering it right away, will there be any autographed copied made available?

Hmmmm, I just looked for it on Amazon. Didn’t find it ??

http://smile.amazon.com/dp/0993442307

Hi Paul I tried to enter my email and a not saying ” this requires a unique entry and [email protected] has already been used??? Does this mean you have record of my application to be kept informed?..

I have cleAned off a spot on my bookshelf for this! I can’t wait to read it. Congratulations to the godfather of hand tool woodworking!

Modern life has too many deadlines

will the bench height guide be in the book

Congratulations Paul and Thank You! I will certainly be ordering your new book as I’ve learned so much from your other book, YouTube, blog and dvd’s!

February is better for me anyway. Spent too much over Christmas as usual. Will give me a chance to save for this. A must have book for sure! Sounds like it will be high quality and made to last. Thanks for all your hard work putting it together Paul. Can’t wait!

Hello Paul,

Happy New Year to you and your Family.

I signed up a while back do I would get a notice when your new Book came out do I need to sign up again? Or am I good.

I’m still drawing my Cabinet to build but Im a stuck trying to decide what to do as far as the Doors and Drawers are concerned. Is it appropriate to ask you here since Its not related directly to the subject’s Heading.

I hope so If not just don’t answer. I promise not to get my little feelings hurt. You have already helped me so much I don’t want to get greedy There’s only probably a few hundred thousand that needs it worse than me.

For Shop space reason My Cabinet needs to be 42 3/4″ Wide x 25″ tall x 16 3/4″ Deep.

2 Doors would put me at 20″s per door and 4 doors at 10″s wide. Im not liking the way that’s coming out.

Would you split the opening up by 1.618 / 42 3/4″ and have one side 15 3/4″ and the other side 25 1/4″ and put 2 doors on the wider side and 1 door on the other side.

For a stupid reason I’m going to have to make this cabinet so I can lock it up. for now, so If I were to put graduated drawers on the 15 /34″ side from top to bottom I would have to put a lock in each drawer so I thought If I set the drawers in say 1 1/4″ I could just put 1 door on that side that’s flush mounted and put the lock on it.,…. and then 2 doors on the other side.

That’s the only thing I can come up with so far…. I’m all ears for anyone out there with some advice on the subject. Muchas Gracias por molestarse.

Chris

I look forward to purchasing another book from the master of masters of woodworking. Paul thank you for all you do and have a great new year.

As no one else has responded on this can I offer some thoughts, Chris. You have clearly thought through the options – including the use of the golden ratio, but you haven’t seen said whether the problem you have with two wide doors is aesthetic, structural or functional. Yes two wide doors might look odd but they might be what you need depending on what you want to store in the cupboard. On the other hand if the open doors would get in the way then three might be better. Make a quick dummy cupboard front from cardboard or hardboard to see if it’s what you want. If you are worried about the structure, I am sure Paul would say that provided you use top quality, well seasoned wood with tight, accurate joints, there will be no structural problem, just more of a challenge to get the doors to meet in the middle. Paul in his masterful classes gives us the tools to make any cupboard of any size, so the choice must be yours.

Thank you….. for responding to my question.

David,

I had pretty much giving up on getting any responses here.

Whats really funny , at this very moment Im in the shop working on these drawings, so you must have some of that esp stuff some folks claim to have. Lol

But Yea, Im running out of room in my shop to put any more Cabinets so Im having to build it according to where it will go and I really need the room of a larger cabinet due to my addiction for vintage tools.

I do understand this is a Blog and not a forum what ever that means. But I’ve never had much luck in getting any responses on the forum pages.

I do pretty good at building furniture but I’m far from being a seasoned amature. As far as my materials are concerned I try to buy the best I can get from only the sawyers with excellant reputations.

My biggest issues are designing like this one. Sure I can just draw it, Build it and deal with it, But I was thinking If we all could help each other with ideas and previous experiences then maybe it would help all the ones like myself become more confident and a better woodworker.

For myself, I can’t travel” Disabled” so unless a teacher is coming to my city this is all I have as a tool to help me improve my skills……… and————-

I know that some people get mad at me for asking so many questions and long ones too that’s their prerogative , but my intentions are always meant to be in a good way.

Like this question here. I have no doubt there are lots of woodworkers that run into this same problem all the time so even though I probably can figure it out eventually it was not just meant for me.and me alone. I think it was a good solid legitimate question.

Ive decided to go with the three doors, and instead of graduated doors Im going with six drawers 2 1/2″ deep and the a 6″ opening at the bottom for Tenon saws. I think I saw a “Saw Bin” in the bottom of the cabinet Paul uses in the shop on the Masterclass site.

But I’m still not sure how much clearance I need between the flush mounted door and the drawers. Is 1/8″ enough. In other words on the left side where the drawers are going to be my 1″ thick door when closed cant hit the drawers. Ive never done flush mounted doors where there are drawers are involved. The door is 1″ thick so set the drawers back 1 1/8″ or do I need to go back further.

Thanks again David I do appreciate you help.

Cheers

Chris

Hello Chris, Apologies for missing answering. Sometimes I do just miss and sometimes I get so many I can’t keep up. Anyway, David did a great job as always and his helpfulness shows his willingness to be a solution as are many others committed to helpfulness. That’s what makes the work we do so very amazing.

Congrats Paul and team,!! I’m very happy that the book is ready and that soon we’ll be able to buy it. Happy new year to all and keep up this remarkable job you have been doing.

Paul, congratulations on what I am sure will be a “job well done”.looking forward to it.

Will the book be made available to purchase in any eBook format (eReader, ePub, Kindle, PDF, HTML etc)?

I don’t think so, at this stage anyway, Martin. When we do online and digital content we try to make it a combination of text, video and images. This book is our attempt to provide a cohesive source for information about the tools. It’s more about legacy and longevity so I don’t think online versions tick the boxes at this point.

Thanks Paul, I understand you reasoning it does fit better with your “traditional” way of doing things, a love of which is the main reason we all follow your lead.

Thanks again for all you do, you are so generous with your knowledge,

Here’s wishing you and yours a Very Happy New Year!

Martin.

Sad to hear that there won’t be a PDF version. I’m from Argentina and getting books from abroad is a real pain because of some custom regulations. Hope you decide to sell the PDF version at some point in the future.

I am looking forward to seeing the beautiful drawings. I will use it with pride.