A Router Too Young to Shave!!!

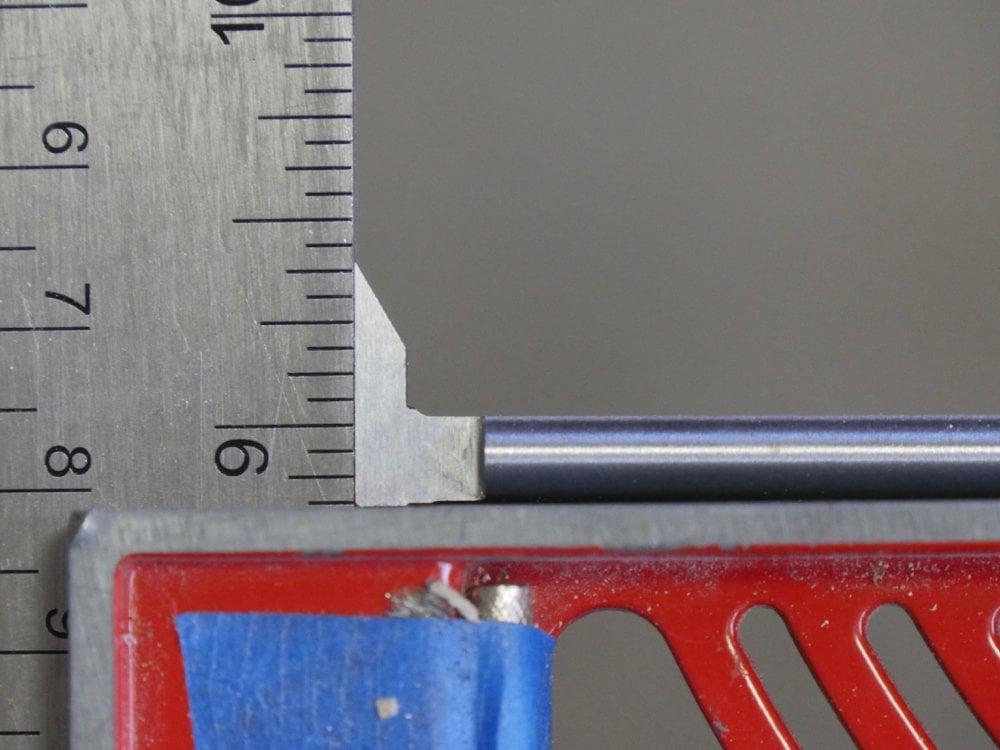

It happens frequently enough. You buy a tool and it looks good, but then you start to work with it and it doesn’t work. This was one of those more awkward situations that unfortunately happened in front of a larger group of woodworkers looking for shavings when none came. I say unfortunately because the tool itself was well made and priced right, but it was also disappointing because the other factors surrounding its manufacture seemed sound. At first glance the tool looked like it should have worked, but then I know something I have studied extensively with router planes and that is that the cutting iron must have a relief angle from the cutting edge on the larger flat face opposite the bevel forming the cutting edge. Here you can see that the foot is dead square to the stem.

In other words the cutting iron cannot lie parallel to the face of the sole of the plane, it must rise up from that cutting edge to the heel of the foot-shaped cutter.

Of course what happened in this case was the tool was never tried by its designer, manufacturer or by any crafting artisan on the wood itself. Of course logic prevails; how can it not work? By the time it was on the shelf and offered for sale it was too late and the name of the company slightly jeopardised for a few weeks. In my case I was with my friend who stocks the planes for sale and I could show him directly the reason the tool didn’t work. I was also able to make some points for him to perhaps work with the tool maker to make suggestions for other considerations for improvement or correction. In this case, as far as tool looks goes, the design was fine. The size of the router plane was very nice and it was indeed nicely made too. So now let’s take the plane apart and say what would make the plane a best seller all round.

The cutting iron

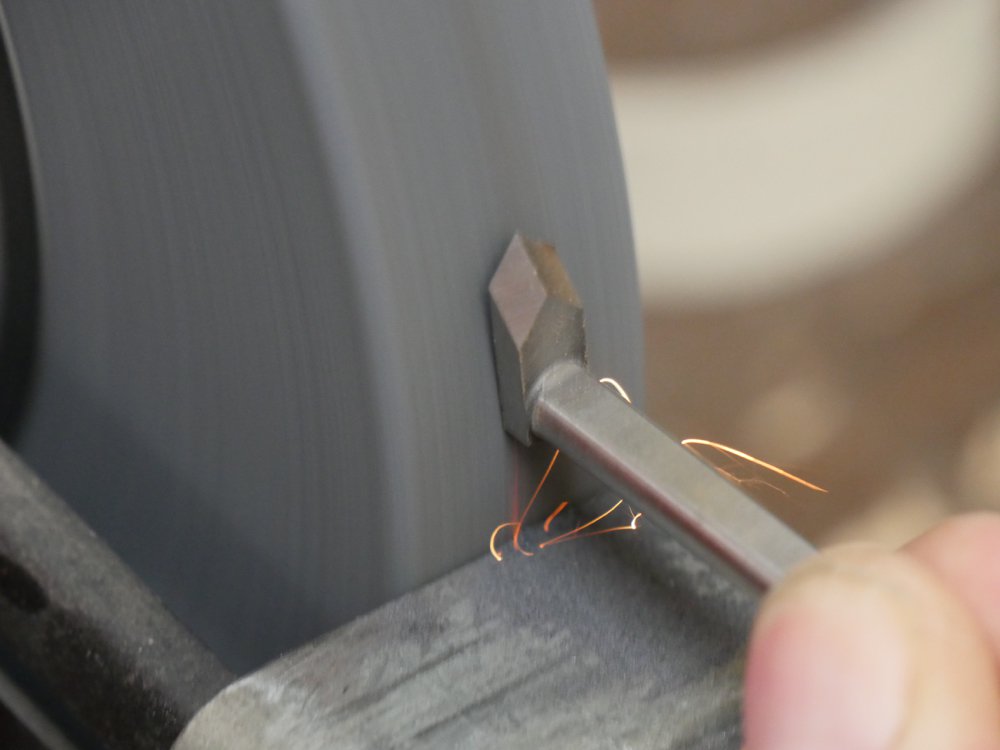

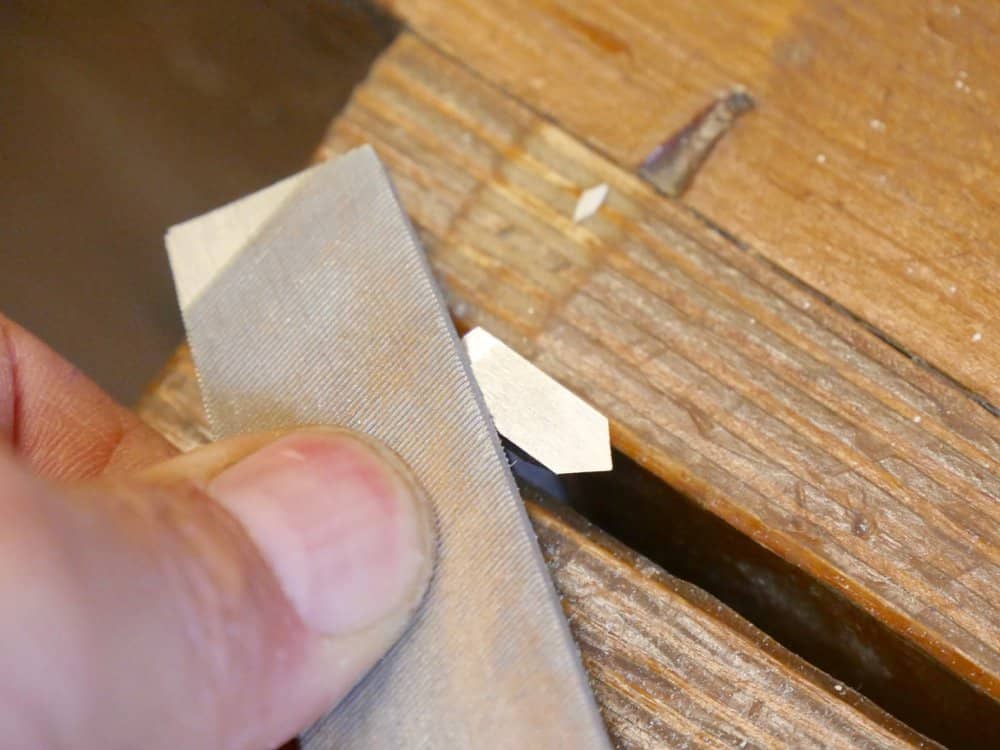

Thankfully the fix is simple and takes but a couple of minutes with a grinding wheel.

Once done the cutter is good for the rest of its life. Here I did just that. I ground the underside of the foot in a straight line from toe to heel and then used the diamond plate to finesse the work. Further polishing and refinement gave me a good cutting iron and I was ready to go. Oh, and the steel is hard. I tried to file mine with a flat file and it barely scratched the surface.

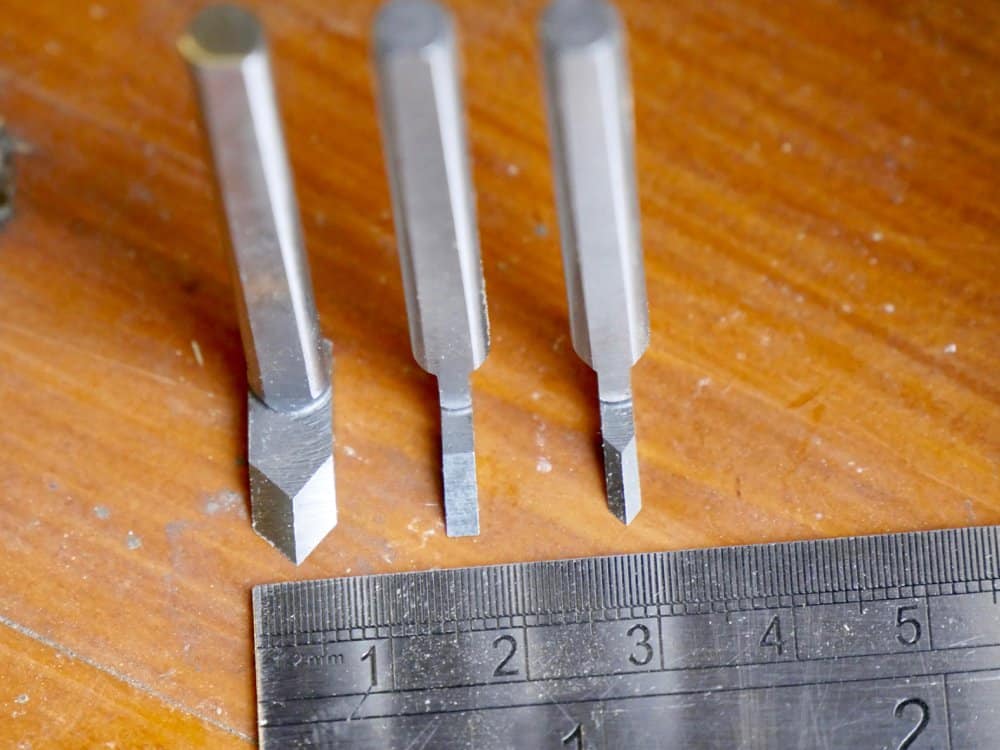

Cutting irons

The plane comes with three cutting irons and whereas I might dismiss all three and say give me one good one to the right size and square instead of the others, I thought that the others would be very useful in some of my work not the least inlaying recessing tight internal corners where the angle might be impossible with a square and wide bevel.

The cutting irons provided at the moment measure approx 6.4mm and 2.4mm wide, so around 1/4″ and 1/8″. Such sizes are actually arbitrary for most work because of course everything we route down is wider than the cutter width. 1/4″ and 1/8″ are handy sizes. I also think that a 10mm cutter would be a very good size for this plane too. A 10mm cutter is good for most of the general recessing work we do that involves routing down recesses such as housings and housing dadoes. The cutters already in the blades provided are excellent for small work but too pernickety for most of the work we engage in. We choose the cutters to match the work, so a narrower recess is usually scarcer and therefor lessens the need for narrower cutting irons.

The sole of the plane

Most routers have a flat aspect connecting the two sides of the sole so that the router is supported over narrower edges. Without this the router cannot be used on say the edges of thin (narrow) wood. In this case anything less than 20mm cannot be routed. For 95% of general woodworking this plane works fine, so I would not hesitate to buy the plane at all. Here you can see the plane slips down over the face and makes depth of cut impossible to control. This then means that the cutter gouges in on narrow, unsupportive edges. It would have been better to have the sole span the gap at the rear half of the plane in my view. That said, again, for 95% of work the plane works great as can be seen below.

The front arch gives clear visibility to the work and no fibres build up at the fore edge for stopped recesses such as stopped housing dadoes. Something other manufacturers have failed to see.

Adjustment

In this case the plane is adjusted by pinching the cutter and setting it near to depth. No router plane is intended to hog off large amounts so in most cases we have reduced the depth with a chisel. The plane refines the depth of cut and goes down incrementally by further adjusting the depth of cut by half a mil at a time. To do this we pinch the cutter at the top of the stem and use the top edge of the plane to micro adjust the depth once it’s set near to depth. The setscrew can usually be set by finger and thumb pressure but a full lock-on is achieved with a screwdriver. This makes it less convenient. The best method is a thumbscrew and nothing comes close for solidity, speed and effectiveness. If they were to change to this the plane would be greatly improved too.

Availability

With the corrections made I hope to see this plane enter the world supply. We cannot get the plane in the UK but when we do I will likely look for the cutters to enhance the functionality of mine. It’s a good plane.

Conclusion:

Grind the foot to 95-degrees instead of 90 and the problem of functionality is solved. Provide an added main cutter of 10mm and also an 8mm cutter but both square across. Not totally essential but definitely a winner for me is the fill in the rear part of the sole so no gap there.

I loved the overall size of the plane. I also liked the ‘wave’ shape that so suits the hand. This is not new, but it was never really manufactured in quantity, yet the shape combines with the knobs for finger gripping.

For small router planes like this it is common and adequate to pinch-set, but I am sure that this plane/tool maker will want to make a version a bit larger with a precise adjustment mechanism. A simple enough addition.

A thumbscrew to replace the slotted head would greatly improve functionality.

The plane is made by Luban. I am waiting for a response from them so I did hold off publishing but there has not been any reply so far.

great review, I know it’s not yet here in the UK but when it does where do you think it will fit in price wise compared to say the small black one we can currently buy here ,

A good write up but I fail to see the brand or where you purchased it was that intentional I haven’t seen that tool in any catalog

It is a Luban.

Great article and even greater title.

Daft bat, which router plane Paul? Come on 🙂

Paul,

I admit to being a tinkerer, but I think that you are giving this company and others like it a pass on producing unusable tools. If they don’t see the need to design something useful, let Lee Valley, L-N, or anyone else produce it and EARN the money.

A used 100 year old router would have been less work to use.

It would be more useful show how an eyebolt, wingnut, replacement router iron and some timber could be made into a router since there is creativity involved and not cleaning up someone else’s mess.

Oh, I like to give toolmakers a chance. I liked the design more than all the others. I’ll wait to see if they can rise to the challenge.

hey Paul, i know this is off subject a tad but I was tuning up a Matthison wooden jack Plane last night. I bought a while back. It’s in great shape but the sole has a convex in it;s length and a very small twist at the heel.

I’ve watched your video many times over the past year or so so I’ve seen how you straighten them out with a #4 . I’m not as proficient as you with hand planes and I don’t want to mess this plane up, it’s that nice.

So I was wondering do you have another one of those cool tricks you know so well that I can use to flatten the sole . I do enjoy learning from you . It has transformed me into a better woodworker that I never thought possible in just the two years that I’ve been a subscriber. Best Job I ever had. Lol Thank You.

Has anyone found a link to the plane? I google luban this and that and found nothing with a price.

Paul,

You don’t appear to mention what the main body is made from as some materials tend to mark the wood and I prefer a bit of weight it looks like it could be aluminium

Tom

It’s steel, powder-coated top. Weight isn’t really an issue with router planes this size because generally they are used for smaller work. In this case the blade automatically pulls the plane down by virtue of the single-sided top bevel.

I think Quangsheng are the manufacturers of this router plane as they do a luban range of planes.

All the critical components you mentioned already exists on the Veritas small router plane, why bother with this cheap chinese version.

I don’t think that it is a cheaper Chinese version, just needs a little help to get it right. I liked the whole concept of shape and size. I find it a refreshing alternative for consideration. Seems to me that the Canadian model and the Taiwanese model are both imports if sent to other countries so both are on an equal footing in supplying the needs f woodworkers. Of course Veritas will always be a favourite maker of mine but it shouldn’t stop me from considering any other maker.

If this is a Luban product then it is simply a re-badge of the same make as Woodcraft planes (made in China). These products go by many names, I have only seen Luban here in Australia sold by a local importer. Other names I’ve seen are Juuma and Quangsheng/Qiangsheng. I’m sure there are more.

Woodcraft planes are highly regarded and made to Woodcraft’s specification. They have been through a few iterations since hitting the market which is good to see because it means they are getting better. The planes are very close to being 1:1 copies of Lie Nielson planes, but some may argue that it’s due to both being based on Stanley Bedrock designs. I know not everyone feels the same way, but for me there is a ethical dilemma buying these Chinese planes.

I was always under the assumption that Veritas made tools in Canada, I had no idea that they produce overseas.

I think they do make almost everything there themselves or through companies producing for them, just a few items are made in Asia. My comment was from the perspective that I live in the UK therefor an item made in Taiwan and north America are imported goods for me.

Even if Veritas did produce in China they would pay more for higher quality work. The chinese craftsman is a highly skilled and talented worker their history proves nothing short of this but like our predecessors they will work up to the standard to what they’re paid.

Companies and corporations need to be held accountable for their actions until they put their money where their mouth is and start living up to the reputation of their own predecessors.

Oi Paull, muito interessante esse teu artigo, sempre que temos problemas no uso da ferramenta, achamos que é incompetência nossa e nunca um defeito da ferramenta, esse artigo alerta para isso, mesmo uma ferramenta de nome pode vir com problema.

Tomei a liberdade e repliquei esse artigo em meu blog? Ah! E se falando em Madeira… no link: eseck1.blogspot.com.br

dedicado a fornecer projetos gratuitos de marcenaria.

Bought the latest iteration of luban router p!and…now has four irons and a large knurled locking screw.

The irons are still ground 90 degrees…not 95 as you suggested. I ground the irons and honed…work excellently.

The extra irons are very handy for use in cutting gauges and other wooden router p!ane like Derek Cohen made. Also made a Preston type rectangular plane…great for

Tenon sizing.

Thanks for suggestions to luban and glad to see they complied.

Geoff ames

Usa

Have been making wooden bench planes and find my small luban router plane and tiny cutters very effective to flatten throat areas.

Geoff Ames

Strafford,nh,usa

Yes but they have made the alteration to them now. At the time they would not work because they didn’t understand the dynamics. That’s all I was addressing. They may well still not understand but they did make the necessary changes.