Eastern and Western Saws Part I

I have considered this issue for a long time–a very long time. I always come back to the same place. In fairness to all, it is most unlikely that I would actually recommend new woodworkers to buy into and use Japanese pull-stroke saws. I think with good reason. Looking at the high standards of Japanese woodworking it is not because the saws are inferior tools, more that I do prefer western push-strokes, but then it does go further. I will get to that as we progress through this. Also, it does have some to do with how I was raised, yes, but more than that, I don’t believe that pull-stroke saws are superior in any way. That said, as it is with many things, often an alternative option might well perform better when used in certain tasks or in tight corners or on a specific application and then too by an experienced user of the particular style or type of saw. No matter the direction of the cutting stroke, one saw will often outperform another. That goes without saying. I suspect that this may well be a controversial issue. There is a lot of claptrap coming mostly from writers and presenters who are often the least experienced of all.

I think that it is true that modern-day engineering creating continuous repeatability without the use of people is today’s normal. That said, it is truly amazing stuff too. A man sits in an office that is completely isolated and detached from the production facility. He determines stock levels at the click of a mouse, determines demand and then arranges shipping details before hitting the send button as if a page to the remotely disconnected connected printer. The CNC kicks in and everything begins spinning and whirring like in the Charlie and the Chocolate Factory film. The out tray is virtual on the screen and someone somewhere in East Asia, three thousand, five thousand miles away lifts the boxes filled with saw blanks to the finality of the assembly line and soon they are out for delivery with DHL, UPS or some other equally detached outfit stuffing it through our letterbox.

To consider today’s mass-manufacture of Japanese-style, pull-stroke saws in the continuum of Japanese culture where saws were once made from hand-hammered and hammer-drawn-out steel as part of the same mystical creation coming from the art and effort of skilled artisans is delusional at best. The same is true of Spear & Jackson thrust-cut handsaws which come similarly from Taiwan in East Asia in the same way. They are made with both impulse-hardened teeth that cannot be sharpened and then as sharpenable versions too. Spear & Jackson allude to their vintage past of 250 years in saw making to disingenuously present their credibility when no one in the Taiwan production facility has any knowledge at all about the tempering and tensioning of steel plate to effectively create the hand made versions made in the late 1700s and on throughout the 1800s. Imagery in the digital world of creation creates strong impressions that can be far distanced from reality. Sparks flying from the blacksmith’s anvil as the hammer strikes the red hot steel, pouring molten metal in flasks of sand and such. From the black and darkened atmosphere of an old-world forge and foundry sparkles on hour screens, a pirouetting hard-point saw spinning on its own long axis until it makes that final stand and we in awe by that much-needed hard-point saw into our stable of fine tools.

Tomorrow or sometime very soon I will put more flesh on these bones. Stay with me. Both Western thrust strokes and Eastern pull versions obviously have their place. Not knocking either.

As an extremely inexperienced woodworker I don’t feel I can comment on the technical aspects of either tool. I’ve never used a Japanese saw despite almost buying into the “they’re better than western saws” hype that a lot of YouTube woodworkers go on about.

All I can say is this – it makes me think of the genius marketing magic trick that got an entire generation of men to get rid of their cut throat or safety razors and buy plastic constructs that you throw in the bin once they are blunt. It doesn’t really make sense there and I can’t help but feel it doesn’t make sense when it comes to hand tools.

In a world that urgently needs to become more sustainable I feel that disposable saw blades (when saws that can be sharpened are still available to buy) are wasteful and unnecessary.

Yes, Chris. Exactly. And I got fed up with modern disposable plastic ‘multiple at once’ blades last year. So I at last grab cuttrought razor that friend sold me years ago. (It took me literaly three hours to shave and whole lot of consciousness – for the first time. Plus nondominant hand for the left side of the face. It was only one tiny nick that happened. Allmost didn’t happen. But it was worth it. Matt at RazorEmporium explaind how Gillete have put out expendable blades for safety-razors mainly to allways buy more, obviously.

In addition to the basic differences (resharpenability, fragility) my main concern with Japanese saws is this:

When rip cutting, the angle of attack needs to be with the grain or “downhill”, which requires an up pull that is not very practical in a vise – you also don’t see the cut as well as it’s on the back side of the piece of wood.

Looking forward to your continuing thoughts on this topic.

My own take on Japanese style tools is fairly simple. I’ve heard many fantastical claims from the vast superiority of their steel to the zen-like feeling of euphoria a woodworker receives by pulling towards himself, an act of taking in, rather than pushing away, an act of aggression…

Do I buy any of it? Not in the least. Japanese tool steel is fine, Japanese chisels are very nice, and Japanese planes work nicely. But there is no mysticism about them in the least. They operate the way they do because traditionally Japanese woodworkers work right off the ground in either a sitting or kneeling position. This position has benefits and drawbacks, and one of those drawbacks is that push style planes and saws are far more difficult to use in that position. You cannot rip saw a board when sitting down 6 inches from the ground with a push saw, it just doesn’t work. And hand planing a board with a western style plane while sitting down is equally as awkward, or at the least it is far more ergonomic to pull the plane from that position. And that is why they work the way they do…no better (or worse), no magic or mysticism; just ergomics.

You’ve got it right Bill, they’re simply different having evolved in the eastern countries and how they work. I bought a Japanese saw, I like it and it works fine. I prefer the angled handle of a western saw to the straight handle of a Japanese one. I’m not so keen on the planes as I can’t ‘,as easily walk’ a long board as I can with a European plane. That said, I like the simple tap with a hammer adjustment, much as I now prefer traditional wood planes to metal planes. Less friction = greater ease of use.

When I was a handyman I found them great for cutting pvc pipe.

I bought a Japanese pull saw purely for the narrowness of the kerf for fiddly work such as cutting nock reinforcement slots in medieval style arrows. They work nicely for that particular rip cut. As to disposable saw blades, once they’ve died I re-purpose them into cabinet scrapers, etc.

Hmmm! How many scrapers does a body need?

As many as the number of moulding planes, plow plane irons you have plus one curved and two straight ones. 😀

Well leaving aside what type of saw is better it is fair to point out that there actually are resharpenable factory made Japanese saws to be found for pretty much the same price as the western type saws of known manufacturers. And of course then there are the “real deal” japanese saws made by blacksmith. Given the price and fragility not a beginner saw but they are out there too. Also fair to point out that as far as the crosscut saws go the western type is probably somewhat easier to sharpen. Anyone can learn to sharpen a rip saw right?

I find that the pull saw is good to have lying around; there are times the pulling action suits me better than pushing. But once that saw gets too blunt to be useful, I will repurpose it to a scraper and a piece of firewood. I will not buy one again, as I now have two S&J traditional skew back saws (now walk it off, Paul! 😀 ) and a Veritas dovetail saw. There will be bought other saws, of that I have no doubt – but they will be resharpenable and push stroke. I’m getting used to the push stroke and how to control it well enough. I also find the pull saw difficult to control on long cuts – it is by no means forgiving. The wrong posture, not pulling straight enough and a blade whipping about gives less than satisfactory results.

The only reason people say they are faster, I’m guessing is because they haven’t used a properly sharpened western saw – or have forgotten how it felt like when they where fresh off the file (which means they don’t sharpen that often). Those pull saws ARE very sharp and do work well – but they become very expensive card scrapers… My S&J traditional skew back saws won’t (plus, they where pretty cheap to begin with).

Paul, thank you for focusing on such “controversial” topics. Too much marketing hype and uneducated guesstimation going on in the woodworking for hobbyists world.

I’m sure S&J traditional skew back saws would sell like crazy if they anodized them red, blue, orange or something. THAT is the trademark of quality, must-have-to-make-anything, genious, never-before-seen, you-didn’t-know-you-didn’t-need tools, it looks like…

Ad a beginner I bought an economic German-Made Rioba saw that is now sulla, is there any way I can resharpen it? Thanks and please keep giving us those very inspiring videos and posts

Paul

I’ve followed your bogs and videos for a long time and I truly admire your craftsmanship and enthusiasm for your craft. I’ve been an amateur woodworker / furniture maker for almost 40 years and I have to say whenever I can use a circular, chop, radial arm saw or bandsaw, I do. May be that would be different if I had your skills. However, I think it’s the chicken and the egg debate. Perhaps if I didn’t have the luxury of the power saws, I may have also developed the skills you posses. You can use a Tenon, Crosscut and rip saw like no one else I know. Over the years I’ve purchased some high quality back saws and tried to use them like you but despite my very significant investment, I rarely get a tenon shoulder that I am 100% happy with without turning to my trusty should planes. What I find is that the Japanese pull saws with their ultra fine teeth and thin kerfts require less skill to deliver a finished cut. Please keep up the blogs and videos. They give me a great lift when I turn on Youtube at midnight every night.

This is debate that can never be won. No matter what tool you are using it takes technique and skill in the particular use of each tool. If one is curious and has a desire to master different tools he will develop the skill and technique to do so no matter where they are made or who made them. If one is set in their ways then there is nothing more to learn. I have seen skilled musicians take cheap guitars and make them sing and i’ve seen amateurish musicians take expensive guitars and make them sound cheap. Whatever tool you choose to buy just learn to use it well.

I guess you’re right, Wayne. If someone would have given me a pencil and asked me to draw a saw when I was a little boy, I would have drawn a frame saw because my father had one. Had someone asked a boy in Japan to draw a saw he would probably had drawn a japanese style saw because that was what he knew. The fact is that people all around the world have been able to work their wood for thousands of years. For boats, houses, tools and much more with the tools they had. In the ancient times they would most likely not even know that tools could be a little different in another part of the world – or in the next village. And they would have been extremely careful not to spoil or break their tool, because it wasn’t easy to repair or even replace.

Today most people can afford to buy the tools they like, even if they don’t need them in their professional life. We even have the privilege of being able to have passionate discussions about details and differences concerning our tools – and those of others. But it’s interensting and fantastic, we ought to be thankful for that.

I once read an article about the world’s best camera in a magazine about photography. The author claimed that the answer to the question was this: The world’s best camera is the one you’ve got with you…

So above all, let’s enjoy and improve our skills by working some wood – with the tools we have

Really well said. Japanese craftsmen have been producing beautifully made pieces using a unique set of tools for at least as long as western craftsmen. There can be no argument that in the hands of a true master, a pull saw can produce results just as good as a western saw (in the hands of a western saw master).

The issue with resharpening is a more a consequence of the recent popularization of pull saws intersecting with modern consumer preferences (as opposed to being fundamental to the pull saw’s heritage). Most modern consumers don’t want to be bothered with sharpening a saw, so even most western style saws have induction hardened teeth these days.

I am very much a beginner at hand tool woodworking, and have tried both. In my very limited experience, I find that the pull technique to be less fatiguing than push, but that push is faster and maybe a bit easier to keep on track. Of course, your mileage may vary.

Hi Paul

I am a big fan and appreciate your wisdom. I also thank you for your kind words about America. It warms my heart that you enjoyed your time in Texas.

My interest in hand tools started about a year ago. Due to my lack of skills, I was initially drawn to Eastern saws after dismal results with Western saws. My skills and confidence with Eastern saws certainly improved. Not surprising, I started collecting Eastern saws and received more than a few packages from Japan! Thankfully my wife is understanding and my kids are amused with my obsession.

Something happened last week and I am now searching Craigslist for Western saws….

I needed to make a quick crosscut on a 1×3 and was in my basement far from my Eastern saws. Staring in my face was a dusty Stanley Western backsaw with a plastic miter box. So I grabbed it and loved the feel and results. Boom. I then ran outside and sawed through a bunch of boards. Too easy and the cuts were square. I liked the weight of the saw.

Here is my take…..The Eastern saws were a great trainer for developing my “approach” and “mindset” for making good cuts. I don’t plan on selling or giving-up my Eastern saws but certainly will be adding and using Western saws in the future.

When two years ago I leafed for the first time through the pages of the catalogue of a German woodworking supplier, looking for panel saws, I was amazed: there were no panel saws! 17 pages of Japanese-style saws (I just counted them again before typing this) and 1.5 page on Western-style saws (mainly back saws). Hardly a single specimen of a normal saw. ‘Normal’, as in, what’s normal for these regions and has been in use for centuries by our ancestors. There is one saw in there that looks like a panel saw but has Japanese-style teeth.

Seems rather unbalanced to me, but then again, I am not making a living from selling tools. I have no doubt that that company (and others like it) simply sell what’s in demand. Myself, I figure if it were good enough for my grandfather and father and served them well, it surely will be good enough for me.

Mmmm. Never had a crosscut saw before. My old Disston was filed rip. Our youngest son gave me an old Disston he found at the dump. Restored it last winter and finally got around to filing it last night and filed it for crosscut.

Should have done that years ago. Works beautifully. And can’t beat the price!

Just a little guidance from Mr. Sellers and his saw filing video….. Thank you!

I appreciate Paul’s wisdom and everybody’s words. I like my Western saws. I also like my dozuki saw for thin, clean dovetail cuts. It is impulse-hardened of course, but I take care of it, and it lasts a long time. I can’t really speak to any other aspect of Eastern saws, except that I am not a fan of my particular ryoba saw.

Starting out years ago I couldn’t figure out how to hold a western saw (Disston carpenters saws), Japanese saws and their action made sense to me, and opened up hand tool woodworking to me (I come out of machine shops). Just as with western saws, there are variety of eastern saws for a variety of purposes, one needs to learn what’s appropriate.

I haven’t invested in western saws since, but often look at the Veritas, would love to try that.

When I was primarily a power tool user, I swore by the Japanese saws. This was due to the fact that I was spending all my money on power tools and accessories, so that didn’t leave enough in my budget for a good western saw. Or at least that was my excuse at the time. Looking back–not very far, I’m still a relative newcomer to hand woodworking–I think it was more a matter of fear or laziness. I had my Dad’s old panel saw, but always had difficulty in starting a cut and never practiced. Likewise, I had no interest in learning how to sharpen it. Once I converted to (mostly) hand woodworking, I realized there are some marked limitations to Japanese saws. The first I noticed was in cutting dovetails. My admittedly very nice Japanese rip-filed backsaw produced a curl of waste that obscured my cut line. That curl when using a push saw is on the far side and so does not obscure my line. And, just as I’ve learned to sharpen my plane irons and chisels, I’m learning how to sharpen my push saws. The impetus for me was picking up a couple of century-old Disston panel saws for less than $5 each, knowing that properly cared for and sharpened, they’ll last me the rest of my life, and beyond.

HI Paul

I was raised in the profession of carpentry as an apprentice starting after high school. This was in latter part of 1971. Dad was a superintendent on jobs starting his carpentry I think in the 30’s so I was also brought up with the American hand saw. However I never did joinery so in my retirement that is my quest. There is much to be said for being able to sharpen your personal saw you use.

I prefer western style saws for my own work, but I have found when teaching young children they have much more success with pull saws.

Thanks Paul.

Out of curiosity, is it possible to take these old impulse hardened saws and put the blades in the oven at that temp that leads to annealing to get the straw color (I think it is like 250 C) so that the teeth can be sharpened?

I ask because I have some impulse hardened saws from before I had discovered you. I don’t buy them now. Just wondering if there is a relatively simple way to save them when they go dull.

Many thanks. Really enjoyed you YouTube Q&A yesterday. I especially like the pace of your answers. It lets you get through a lot of questions and your answers get right to the point. This is another valuable skill you have.

The conclusion is “the right saw is the one thats right for you”. The best idea is to give both a try at different tasks and which ever seems to work for you to achieve the desired result is the winner but maybe a mix of both might be a good choice too. What works good for one task might not work so good at a different task. I love my Veritas Low Angle Jack Plane but there is no way i will part with my little Japanese block plane. I see no sense in collecting a dozen #4 whatevers that do the same job when i can buy different tools that i don’t have if i think they can add a dimension to my woodworking experience. I once tried to interest my brother-in-law to a new tool but he wouldn’t try one and ten years later on one of my visits to him he was all excited about this new tool he discovered. I said let me have a look. It turned out to be the tool i tried to introduce him to ten years earlier. I said you missed out on ten years of use with that great tool because you didn’t pay attention to it when i shared it with you.

Hi guys, I think Paul is right, pull stroke is not superior than the push stroke saws, though I’ve never used a Japanese style saw. To my understanding, the Japanese pull everything to their bodies(saws and hand planes) is because back then(maybe up until 40-50 years ago) they were not as strong and tall as they are today. So pulling things towards the body could give them more strength by using the weight of their bodies. So if you don’t find yourself lacking the strength or not tall enough to work on some pieces, I believe push stroke saws will give you more control once you master the skills to properly use a hand saw.

Hi Lue, is it fair to give a review on something you have never used or know anything about and supposing that the Japanese were too weak and short to push a western style saw?

Hi Lue,

It’s incorrect that the Japanese are or were inherently weaker than people from other countries.

Rather, they do much of their work sitting on the floor or at a very low table. The angles and leverage are different, so it makes sense that a pull stroke would be easier in that setup.

I am going to step out on a limb here- The following is just an observation of application or technique and not the type of saws just the visual use of such. It is not directed to anyone personally. specifically or generally.

I have been watching Youtube videos about saws for about ten years now and according to my observation, I have yet to see anyone in the videos, use an “eastern” saw, who appeared to master that type of saw. They, to me, have all looked like they were just learning how to use one (yes even those that professed to be professionals). Everyone, to me, looked awkward in there movements and application. The cuts were fine, but how they got there looked labored and uncomfortable, dare I say they looked uncoordinated? I’m not knocking the outcome or the product, they just look something like a tall basketball player trying to do a women’s gymnastics dance routine. I would think that if I was new to all this, watching them would not give me a lot of confidence. With that said, most of those on YouTube using western saws look just as contrived and uncoordinated, especially when I see them trying to use a saw bench or leg vice whilst sawing.

I grow up disliking all hand saws- no matter where they came from. As a kid, we had an old very dull western saw that for the life of me, I couldn’t figure out how to get it to cut straight and it wore me out just trying to crosscutting a 2×4. When the “Japanese” saws (as they were called in my area) came into vogue in the early ’90s, I tried them and they weren’t the panacea for me either. They wouldn’t cut straight, the action was weird and they were so flimsy; binding, and torquing around when you pushed the saw back setting up for the pull (technique, in know).

After finding out how to sharpen my old family saw (from Paul), life is now totally different, and the rest, as they say, is history.

When I started switching over to hand tools, I bought a brand new Gyokochu Ryoba saw and started using it. There is literally no learning curve. You pull it towards you, thats it, and the blade is so wide it tracks perfectly straight.

I then bought some brand new Lie Nielsen saws so I knew what sharp was before trying to sharpen older saws. What I noticed is there is quite a learning curve. To be honest, I am still learning how to use these, especially starting a cut. It takes more constant feedback to keep it tracking straight. But the end result is the same.

Long story short, I am using both, trying to use the LNs more to get practice. But when I need to cut something quick and dirty I will grab the ryoba. I know if i damage the teeth I can slap a new blade on it for $20 or whatever.

Hi Paul,

I thought I would share my experience with Eastern vs Western handtools. Some background, I use both a low “Roman” (and Chinese) style bench and a “western” high style bench. I find both styles of saws to be easy to use, when used with the correct body positions. Doesn’t matter if the wood is dry or green. If the blade is sharp and you position your body to saw correctly you will do fine. My next frame saw to make is a Chinese style where the blade is angled to the frame. Why? To see if the blade, set at an angle to the frame is useful for me and help improve my cutting skills on my low bench. Is it superior to a western style framesaw, probably not. But leaning over a bench holding a piece of work with your foot as your QR vise the angled framesaw may be the correct tool.

Using both Eastern style and Western style tools have been about the journey of woodworking and appreciating the process, even body position to do certain tasks such as cutting with a pull saw vs push saw. I will share the fact that after major shoulder reconstruction of my dominant shoulder the pull saw was for many months the only way I could saw due to my limited range of motion. It is the only time I stuck to one style for an extended length of time. I was very happy to regain the full range of motion to again use my push saws again!

It comes down to doing the many things you have shared with us over the years, lessons to pay close attention. Keeping ones tools sharpened, Learning how to use tools correctly, always strive to improve ones skills, and learn from mistakes.

The tools I own that I enjoy using the most are the ones made by an individual craftsman. My blacksmith made Japanese chisels are remarkable tools. I will lament the day when the last of these gentle craftsman pass on. Nothing beats a tool made by an individual dedicated to the art and craft of making a lifetime tool. A fact that you point out to us and one I hope others listen.

One thing which I have only seen on a japanese saw is the little woodpecker starter tooth some of them use for starting in the middle of a board.

Turns out to be very useful when cleaning out the inside of a sawblade kerf… though I didn’t buy one just for that, I simply put my own take on it on the end of my saw float.

Tools in Japan are much more interesting to me than tools that alude to coming from Japan.

I returned to North America in 2009 after 5 years of living in Japan and generally working in Asia for about 10 years. My favourite tourism activity is visiting hardware stores, building sites, grocery stores etc. that give you a flavour of how people actually live.

Japanese saws and Japanese tools we see in the west are nothing really like what the Japanese buy. On the low end you can get some servicable tools at the dollar store (Hyaku Yen). There are numerous dusty old tool shops on the high end with very expensive new/old inventory of lovely Japanese hand tools.

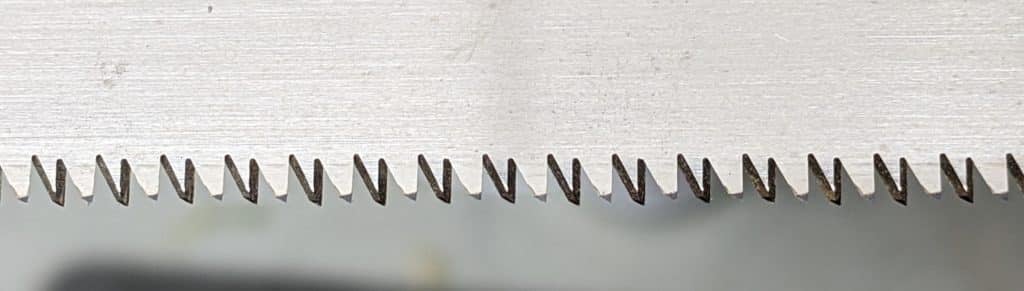

In the middle – generally at DIY stores and mid range smaller shops are everyday stuff that is much like I imagine we could buy in NA in 1955. When you see the variety of ordinary saws (with the pull configuration) along with them are the selection of slender tapered files of quite decent quality to sharpen the very different tooth form.

10 years later I wonder if this is still the case but probably so. Japan like Germany and a few other cultures have reverence and a place of honour for the skilled trades including many manual operations. The tools go hand in hand with that cultural honour.

It’s all about sales.

If you persuade people to buy throwaway saws you will sell tons. If you sell “normal” saws most of them will outlast their owner.

Similarly with sharpening – one oil stone will last for life; all the fashionable alternatives involve repeated buying for evermore.

Similarly with gadgets – persuade people that something is difficult (even when it isn’t) and could be improved with a gadget then you will sell lots of gadgets. Even when they actually make the task more difficult, as with honing jigs!

I own one japanese pull saw. It has a disposable blade and a flexible tip. I only use it to flush trim, for example draw bores. It is a little dangerous because as you pull it towards you it is very easy to nick a finger of your other hand unless you are very careful and remember not to cut towards the hand holding the work. Which is very awkward, This never seems to be a problem with western saws. Also if you hit a nail the teeth break and the blade is done. Sometimes this will also happen in very hard wood. I don’t use it very often.

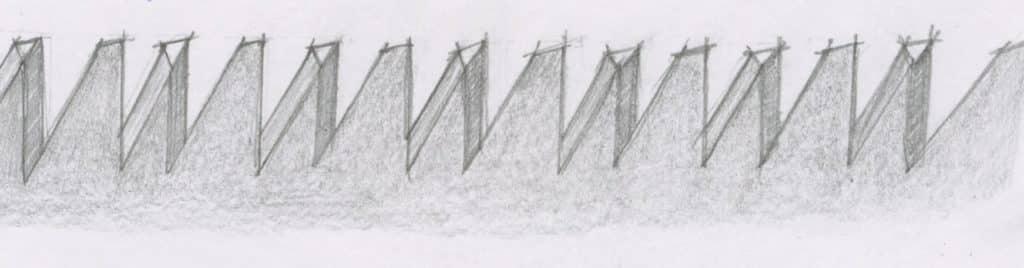

I did a personal review of Japanese saw videos the other week .There were several mistakes being made in the “teaching”. The most common mistake was the use of a Japanese Rip Saw . If you compare the action of a western rip saw the teeth are moving towards the end of the wood. The Japanese saw will need to be used standing at the end of the wood and pulling away from the centre of the plank. The hook shape teeth will not work by standing in a western style position and simply pulling . It took me a while to figure out why pull type rip saws did not make sense as they were explained .

One excellent Japanese video , shaping some very large timber pieces , spells out the rule “Only cut the surface you can see ” .So the advantage of pulling is you “should ” see what is being cut , and that means altering the cutting angle downwards to avoid cutting the opposite face . Western sawing generally maintains the same position .

I showed my son how to use a pull saw and repeated “Pull,—-Pull,—–Pull”. Then said “You need to exagerate that to get the idea in your head . Also the grip should be quite light. That`s a big difference to avoid buckling .

Fascinating how something like a saw have been invented separately on opposite sides of the world. Suppose they are developed until they finally evolve at what is the logical ultimate form to complete a task.

I broke the blades of both of my Japanese saws this week, working outdoors between showers with completely wet horrible pressure treated wood. I should have been more careful but I was impatient and it happened so fast when the blades bound up and the thin blades buckled instantly.

As someone who owns both western and Japanese style saws, I choose certain saws for certain activities. I enjoy and use both! That being said, I’ve found myself drawn more to the Japanese ones over time.

I enjoy both style but, to be honest, I have very little interest in learning how to sharpen a saw. The time that I get to spend doing woodworking is fairly limited and I feel like I spend enough time keeping my chisels and plain irons sharp. So I have no real problem with the idea of using a Japanese saw and buying a new blade for it every couple of years.

But you know what? That is what works for me. It doesn’t have to be what works for you or for anyone else. To each their own.

MDF trim for a hardwood floor while sat on my big fat backside using a mitre block sat on top of my bench hook for an easy access angle for my fine pull saw.

Once I am on the floor with my trim medium superglue and accelerator there is no way I am going to stand up to cut some trim.

Many Japanese carpenters sit down to do wood work according to YT videos that I have watched.

Pull saws do have there uses but they do not replace traditional push saws.

I am used to working with steel but find woodwork and hand tools much quieter. Weld and grind and no one can see your mistakes BUT wood is not easy to disguise you gaps 😉

I love my Japanese-style pull saws for use on moulding and other small pieces. They cut smoothly, and rarely tear out any wood. On the negative side, the teeth are very brittle. Several have broken off over the years while sawing maple, cherry and white oak.

For large cuts, I prefer a push saw or sometimes for long ripping jobs I use a tablesaw.

As one who is ‘good’ with neither, I will say I bought a (push) dovetail saw at woodcraft 30 years ago and thought it a piece of junk. I bought a Japanese (pull) saw 20 years ago and was amazed at how precise I could be. That very thin cut line, it became which side of the pencil line do I want to be on? Now, if I had a push saw sharpened by Paul, maybe it would be a different comparison, but ‘out of the box’, from Woodcraft it was junk.

I use both, East and West, in the situation with suits them best. East on the floor or low bench, west on a low bench and in the vise. Not the other way around. I like the firmness of the handle on West and the elegance of elongating the wrist with East.

Just my experience: western as well as eastern saws do not work, if your skills are absolute beginner level. Most western saws beginner start with are dull tool while eastern saws at least are sharpened.

I don’t think it makes a difference in the result. Both types of saw can obviously be used to create superb quality. Apart from the sharpening aspect I guess it’s a matter of taste and getting used to. Maybe one is better than the other. But people tend to stick to their tradition even when there might be something better out there. It reminds me how many potters in Asia have their wheels running clockwise while people here usually have it rotate in the opposite direction. Is one better than the other? I doubt it but I just got used to our way and I won’t change. Is driving on the left side of the road better than driving on the right side?

About the sharpening: I guess we can’t go back to the 1700s where every saw was handmade by a local blacksmith. I agree being able to sharpen your own tools is a great skill. I know the feeling when people find it odd that I sharpen my knifes instead of buying a new one. But I also see how lathe and mill tools change to carbide. Of course everything can be sharpened. The question is can you sharpen it in the workshop without special tools. Lets be honest. What do you do with dull files? Give it to your local file cutter? I guess production without waste isn’t possible. How much waste we are willing to accept is a personal decision. I enjoy repairing things, avoiding to buy new things if possible. But everyone has limits.

Sorry,but I am going to put the wolf amongst the pigeons. I wonder what the Japanese craftsmen think of western push saws, chisels & planes? Do they think they could ever have built anything from delicate kumiko to mighty temples that are screw, nail & glue free with western saws & chisels? Joints that slide & self lock with micro accuracy?

Hi John C, Japanese Master Toshio Odate pokes a little fun at Western planes on a short youtube video so he obviously isn’t impressed with them. So it is probably safe to say that they don’t feel that they missed anything over the last thousand years and i’m sure Paul will say the same about Japanese planes. But we can enjoy both if we aren’t concerned about traditions in our woodworking and use what gives us the result we are after. Tradition would have left us is a cave with stone tools to work with which might have been okay too. I think perhaps we are just looking for a quiet and dust free experience in our shop where we can enjoy hand tools that challenge our skills and abilities irregardless who made the tool. In a fast paced power tool shop it is all about production but in our shop perhaps it is just about using the tools. In Paul’s wisdom he naturally is going to teach what he is proficient in for over 50 years and rightfully so as a Japanese Master would be expected to teach using the tools he is proficient with.

I have no issues using either Eastern or Wetstern tools as I often use tools on push and pull strokes on a daily basis. I doubt that many eastern makers would use a Stanley #4 as I do with the same dexterity but of course they could.

I’ve noticed this a lot with knockoff planes. And by knockoff, I mean even vintage knockoffs. Stanley originally did everything for a reason but the people copying them, well, just copied them, without knowing why everything was the way it was.

For example I have a Dronfield plane that works fine, but some of the adjustments just seem a little bit “off” compared to an old Stanley.

Also, I recently got a new Spears & Jackson no. 5 for about £23, and all the parts were there, but you could tell that the people who “designed” it were just copying the parts from other planes, and the people who “built” it were just working from plans, or just doing what they were told.

For example, this plane has a frog adjustment screw, but the part of the screw that moves the frog (like a permanent washer) was outside the housing on the frog that it was supposed to move, and when I went to attach it correctly I found that the inside of the frog housing wasn’t even milled out correctly. It’s like the person assembling the plane had no idea what the screw was for and just screwed it onto the plane after the frog was attached, as an afterthought.

We are fortunate that Veritas is taking these old planes and not just copying them but resolving some of the cons associated with them when they reproduce them and introduce new and better materials in their production. But with this you are going pay the price. To me buying one particular plane for quality is cheaper then buying a dozen old planes and refurbishing them. That being said some people just enjoy refurbishing old planes and thats okay if that is the way you want to spend your dollars. If there is an accident at an intersection and the police question four different people on four different corners of the intersection they will usually get four different accounts of the accident because all four witnesses viewed it from a different angle. None of them are wrong they just viewed the scene from different angles.

i watched a documentary on the steel of japanese swords and european swords. it turned out the two handled sword made by the europeans was actually stronger than japanese steel and held its edge better. it seems as paul has said earlier. we have built such a mystique around japanese steel that we now believe it to be superior and see it as an easy way to gain prestige by its use. whilst youtube has its place as an educational tool, it just as easily spreads misinformation which is then taken as fact.

I wanted to become blacksmith (bladesmith-swordsmith), and i allmost bought blacksmith’s equipment at a fleamarket, but it didn’t happen unfortunately. I’s a shame, really. I could have made my own tools and blades for woodworking.

I have been making my own blades for woodworking with little more than a propane torch and a couple of hammers and a file for five decades now. It’s pretty low demand.

Nowadays steels are pretty much standard products. There’s basically no secret steel recipe. You can look up the composition of any steel and you buy them from companies like Hitachi (in case of Japanese steel) or any other steel manufacturer. I don’t think steel for woodworking should be such a difficult thing. Steel is used to cut steel and HSS tools are quite affordable. To be honest I think steel is one of the very few materials we can recycle in large quantities without much loss. You can’t say that about plastics.

My decision to use Japanese style pull saws was easy… there are no affordable western style push saws in my country (Mexico). Not even in Amazon. The cost + shipping of a decent push saw is around $120 USD (which I find ridiculous). Through Amazon a got a pair of Japanese pull saws for 25-30 USD each.

That’s Mexico for you! At least how I recall.

I wish I could find some S&J saws here in the US. On Amazon they are all in the UK and can’t be delivered to the US. At least that what it says on Amazon.

I don’t think that that is the case as I hear others say they have been able to get them.

Jim, I recently ordered both the 7ppi and 10ppi S&J saws from Amazon. Here are the links:

https://www.amazon.com/gp/product/B0043YN9BQ

https://www.amazon.com/gp/product/B0043YN9CK

The S&J Traditional saws were out of stock on Amazon US for quite some time earlier this year, but as of a few weeks back, they were available again.

I am very much a handsaw beginner, but have been very pleased with these saws, both in the amount of effort it takes to make a cut and in my ability to hold a line. I am sure this has more to do with the sharpness of the saw as compared to the rusty old handsaws saws I can remember using as a kid.

My father was an avid do-it-yourselfer, with an eclectic collection of odd tools he scrounged over the years. They always got the job done, but I am positive he never sharpened any of the cheap handsaws he had. I do wish I paid more attention to those tools though, I have a few that I cherish today, but I know I let some slip away too.

Hi Paul from NZ. Two points I wish to make.

First, I don’t see any point in debating the best choice. I have both and use the saw that best fits the situation.

Second, I frequently have trouble starting the cut with the push saw. I know it is sharp. Could it be the set? It seems to catch in a small trough created by on tooth.

Love you advice and approach. Thanks.

I didn’t know there was a debate taking place. I certainly was not starting one even though many have entered into the fray to somehow correct me before I even presented the articles I have been wondering and working over over the years. But like “Paul hates machines” when I like them very much or, “Paul never uses machines!” when I have used them for 55 years.No one has said yet, “Paul hates power routers!” which of course I absolutely do of course, but only because in my younger years I stood over one day in day out for years!

We all hate routers Paul ! but would not be without them either. Some of the tightest tolerance joinery that I know of is made mostly with them, there are three under each bench. They are noisy, messy and a nightmare to use with an extract hose attached, but as you know, they are fast !!

And I will never use one again for anything. I love my life without one.

Hi Paul, reluctantly, recently I purchased a power router with the idea it would help in the process of building an electric guitar.

It worries me before i use it to be honest. With the skills I’ve learned through watching you has seen most challenges put to rest and surprises me just how fast I’ve learned but routing neck pockets and pickup cavities just seems to look a bit shabby when done with hand tools.

Though I’d do anything to not have to reach for the PR. Maybe someday you might make an electric guitar, as a gift.! So many people are making them and posting the vids on YouTube but only one or two with hand tools.

Look I’ve wondered what a Paul seller telecaster might look like..! I bet others too. Best wishes.

I just started woodworking about six weeks ago, and the only saw I had (which I already owned for some long-forgotten reason) was a Japanese ryoba saw. It’s pretty cheap and has the replaceable blade, etc. I tried cutting my first dovetail joints with this saw and could never get the saw to go where I wanted. I assumed this was 100% due to me being brand-new to this and lacking the skills for accurate saw work.

But when I got a western-style (Veritas carcass) saw, I could suddenly cut straight. I think it’s mostly due to having the rigid back on the saw. I dug up another Japanese saw I had which has a rigid back, and it does help quite a bit, but I still feel like I’m more in control with the western-style saw.

In fairness, it’s not an apples-to-apples comparison though. I’m using a $25 ryoba with a replaceable blade vs an $80 saw with a resharpenable blade, so maybe I would have a different opinion if I tried a comparable Japanese saw. In any case, the western-style saw seems just fine to me.

Oh, and the rip-saw side of the ryoba is not good at all compared to my cheap Spear & Jackson that I filed for rip (and I probably didn’t even do a good job at that).

Ian, try filing the first few teeth of the saw. Paul does this in one or more of his videos but I can’t remember which one. I haven’t done it myself but plan to. I’ve tended to start the saw cut by pulling a few times, then pushing. I don’t know if that’s a good way or not, but it seems to work (I just went with trial and error).

I own 3 Japanese saws but use them only for smaller cuts as I have never really got the hang of using them. I also find them deathly slow so I use my Western saws most of the time and always for ripping. I also like the idea of passing my Western saws down to grand-kids.

I can’t say that I like pull saws much, yes I have had them, there probably one or two lying about somewhere, still. They are not difficult to use, but they are far too fragile, I can’t really get on with teeth that can distort on a knot !

What’s funny to me is how many people are saying the pull-stroke saws are more accurate than western saws–that’s the very same as saying metric measurements are more accurate than imperial. Haha…or vice versa!

This from sunny South Africa. I’m sorry Paul didn’t get to complete his work on this subject, but I would say that collectively all that can be said has been said by his readers.

I have acquired – at minimal cost – 6 Disston saws of carious lengthsd and filings and love using them. I have 1 small Japanese pullsaw almost exclusively for trimming dowels and other finicky work. I have tried using it for dovetails and find it satisfactory but harder work than a western backsaw. Sorry – it seems I am joining the club here. End.

Oh, I’m not done on this yet!

Most of the time I’m happy to use my western push saws. They’re comfortable to use, they do the job well, I have got used to using them and know that I can attain high accuracy with them. I have found that I tend to use my pull saws when I’m doing DIY around the home; they seem to need less space to work in and I find them easier to manage when I don’t have a workbench available. One thing I have recently discovered though is that having developed tendonitis in my dominant shoulder, I am able to use them in when I need to make long rip cuts that the use of a push saw aggravates. The double handed pull action leaves me completely pain free.

I have toyed with the idea of getting a Ryoba pull saw, I am fortunate to have the last of the Stanley Professional 26in 8pt handsaws and the matching ripper. Both cut quite well and fit my hand nicely. The saw back is taper ground to prevent binding. Aside from them I have bought a Veritas backsaw and dovetail saw. I know I can depend on their quality control. I have several Veritas planes and there is absolutely no doubt these are good quality tools the minute you pick them up. Thank you Leonard Lee. Who would think a business started in retirement would live on after his passing. Fortunately there is a store mere blocks from me and I am a frequent flyer. Also lately with the Covid thing going on, anything over $30 is free delivery. The only alternative to Lee would be Lie Nielsen but because it comes from the US the same thing costs nearly twice.

I bought a Japanese/German supermarket saw to try it. I find I like its thin kerf and light weight. I also enjoy the two-handed grip. I have learned to address the job with a firm stance and feel I have good control over the precision of the cut. The blade may appear a little floppy and flimsy, but under the tension of cutting, it pulls straight, could not do otherwise. It is very sharp and cuts fast. With fine teeth, I think it best for cross-cutting. It is great for cutting around large diameter plastic pipe too.

In fact I liked it so much, a year later, I bought the rather more expensive two-sided Japanese pull saw from Axminster. This provides teeth for both cross-cutting and ripping. It’s a very convenient form for limited storage space too. I think I may be turning Japanese!

If I recall correctly there was a S&J panel saw that you recommended, a sharpenable one. I believe you even called it a lifetime saw or something to that effect. Perhaps that was years ago, I can’t quite remember, but are you saying in this post that you do not recommend any? I couldn’t quite tell. Thank you for the meaningful and heartfelt words.

I can thoroughly recommend these resharpenable saws. Mine are well tested and I use them every day. For under £25 they are extremely good value for money in that they sharpen well and hold a good edge for an acceptable length of time. Also, they are indeed a lifetime saw.

I agree that we normally lean towards what we grew up with. I have my grandmothers Diston Saw and the western style saws work just fine for me. The only pull saw I have is the small one I used to flush cut dowels. As for sharpening… I haven’t mastered that one but when I do get it down I have a half dozen western saws to fix and resharpen (that I screwed up). 🙂

I cannot cut exactly at the right angle with Japanese saws, but I can do it with western ones. Therefore, my choice is western saws )

For what it’s worth, as a novice using both some if my grandfather’s decent push-saws and some cheapo pull-saws, the pull-saws have one argument occasionally in their favor: they can use a thinner saw plate without needing a back/spine to stiffen them, since being used under tension removes the risk that the blade will bow.

It’s minor. But it’s enough that I do sometimes find myself reaching for them.

May say more about my own lack of skill and the need to better sharpen my saws, admittedly. But I figured I’d toss it out there.

I’m s firm believer that the best tool for any task is the one you’re most comfortable with for that specific task… and have on hand or can grab quickly. I will however admit that while screwdrivers make bad hammers, hammers make worse screwdrivers.

I dont have deep knowledge about metal working, but I know it is fairly simple to “reset” iron and give it a new heat treatment to get soft, hard and brittle or springy iron.

Is this not possible with the saw tips, by using a blow torch?

Maybe someone with sufficient knowledge about the subject can enlight us on this subject.

If possible, it would mean that we don’t have to throw away hardened tip saw blades, but can resharpen them when they become blunt.