A Steady Incline is All in a Day’s Work

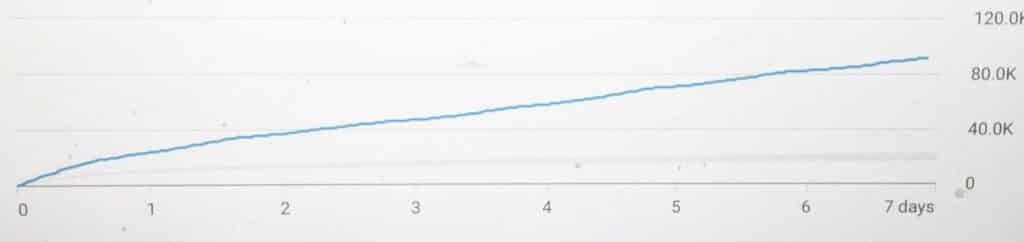

Launching any plane means setting its trajectory and providing enough propulsion power to drive it forward at speeds that will lift it from all opposition until its skyward lift enables it to carry its own weight for great distances to a destination of choice. The destination of my choice? Your garage workshops, your sheds, your basements, carports, patios, spare rooms and dedicated workshops too. The propulsion power? Our joint enthusiasm. Can you imagine that in just one week we have reached over 90,000 hand tool woodworking enthusiasts? Together we did it!

There is more good news today. Though episode two went out last week on our woodworkingmasterclasses channel, episode two is out today on YouTube and that concludes our pioneering into uncharted climes internationally. From hereon, no individual needs to ever buy an all-metal router plane version again! Not unless they just want to own one, that is. This router plane means everyone anywhere can own their own handmade version for just a fraction of the money they might have had to pay one week ago, and without seeing the message saying, ‘Back-ordered – four-week delivery’. And they can do this now without compromising the standards of workmanship we demand from quality router planes too. What I truly love is that we did it together. I am so proud of our team and the teamwork here at woodworkingmasterclasses as everyone plugged in to make it happen. Did you see the stunning videography from Natalie and Will? They didn’t miss a lick in videoing AND editing; those close-ups slicing through the wood fibres and lifting out the waste in slow-mo, the cut lines aligned perfectly with the camera eye to show the exactness beyond the lens. I liken this to the sweet-spot of a direct strike where the COP (centre of percussion) is so smack-on, the ball goes way beyond the confines of all limits. And then too, what about the drawings we did? I thought that these were pretty stunning and we, Joseph, Mark, myself, worked rapidly to pull these together as a joint effort so that everyone could download a very decent PDF to work from.

Yes, I guess that this has become a bit of a boast by me on our small (very small) team of creatives that reach out to woodworkers on every continent with solutions to their problems in woodworking. I hope you don’t mind but they do deserve much of the credit. I have gone from training my children to training and mentoring apprentices to developing woodworking schools with hands-on classes to now teach in an international way that I never thought possible. I have been an absolute maker throughout and never became an academic nor a YouTuber to just make an income. For me, maker first has always been key to my teaching. How many have 57 years in the saddle of making together with 32 years of teaching and training running side by side? Yes, it took many 80-100 hour weeks to make life happen this way, but today I see the impact of all that we have done. And Joseph has been with me every step of the way too. It could never have happened without his support and input.

I remember that we still ran classes during the months up to and during the time we pulled the “two White House credenzas together for the Cabinet Room. Some nights, the sleep for me was just one hour, and then back to it. I recall students asking who the cabinets were for and me not telling. Towards the end of a week-long class, shortly before delivery in January 2009, one of the students came over to my bench the day after Joseph and I had just inlaid the two Bald Eagles in two of the doors and whispered, “These are for the White House, aren’t they? I nodded.

Currently, my workshop is cluttered with piles of cherry shavings and I need to sweep. My tools clutter the workbench from making four small occasional tables ready for our next Sellers’ home project which as a batch production series are almost done. These are those gap fillers for plants, cups, and books under current reading. I am pulling together a thought I have had for some time. My mind races with the thought of a new book or two. I want to produce two books with one for children and one for art. Remember the days past when books had titles like ‘The Boys Book of Woodworking’, such like that? I have such a one on my desk. Well, I want to replace this concept of old with something that will stimulate youngsters as they did in their day. What’s the difference. I want to use my own woodcuts for the illustrations. Yup!

So is the woodcut shown at bottom of post yours? It’s exquisite!

That Eagle inlay is STUNNING

So much agreement on a thoughtful, modern, children’s woodworking book! I can barely imagine the positive impact it may have. Your invaluable mentorship to so many, including me, via your online efforts translated for a younger generation would be a gap-less fit in the mission of passing the life-affirming skills woodworking gives to those who are exposed to it. Congratulations and continued success!

I can see that this is one of your proudest creations, and you have every right to be proud. It’s clear you were a bit uneasy at the effect you had on tool price of the router plane in particular. This is an extremely generous donation to the world, and I am sure many will be grateful- for generations to come. Well done sir.

Yes, kudos to your production team Paul. They aren’t forgotten. Their skill is a key contribution to the Sellers “brand”. Thank you all.

It is nothing less than noble that you have chosen to design and give away your design for the router plane. Thankyou!

You shouldn’t let so many shavings on the floor before you sweep

I suggest intermittent sweeping

Hahaha

Nice piece

Michael

I second everything that everyone else has said–it is amazing. I had a shop class in my (private/independent/public — depending where you are) school. It was one of the best courses I had — it gave me the curiosity and knowledge that I could do things, and 45 years later, I discovered this wonderful source, and my skills have increased ten fold. I currently have projects of “woodpile” spoons — from beech logs in my winter burn pile; I have found one big enough, and I am shaping a quarter log to make the body for a router plane.

Thank you to everyone on the Seller’s team for the videos, the drawings, and the enthusiasm to share this info with all of us. (I just got a cheap Stanley 78 without any accessories except the blade — my next scrub plane!).

Every day is a remarkable woodworking/learning experience for me, and the two videos on the router plane were no exception–rather, truly exceptional!! Excellent presentation, Paul. Ever since I discovered your videos and blogs, about 6 months ago, it seems I have a steady stream of packages arriving from across the pond!

Today an offer of mine was accepted (which I didn’t expect) on a #5 1/2 Stanley plane. In the mean time I bid on two similar planes, thinking I might win one, not thinking three might be in the making. Look what you have started!! Love it. Keep up the good work and remarkable rhetoric. Looking forward to further projects.

The videography in your vids is awesome , It got the job done with the first bench in the back yard but now they are really beautiful and IMO better than a lot of professional work. I’d love it if the production team did a behind the scenes video, so cool and great to see your lifestyle approach in action even if it’s in a different media.

Re: Children’s book

As much as I’d like a new furniture making book please please do the children’s book! I can tell by the way you talk about your children and grand children the book will be great and of interest to “boys and girls of all ages”.

When you talked about getting the printing gear I thought we’d see you publishing mini-manuals like the drawing for the router plane. But now I’m hoping you’ll combine the projects in the PS’s house into one volume. Now that would be useful and interesting. Telling the story of what was easy, what was hard and generally talking about making multiple pieces of furniture over time.

As always thanks for your insights, not just wood, but on life in general.

I’m a great fan of yours and getting together materials for the router plane. Your impact in Australia is reflected when I searched the internet for knurled nuts and found a supplier in Victoria who responded to my enquiry “are you making a plane” ! Sure enough they’re waiting for extra stock!

Cheers Doug

Now Paul….what would George say about all those shavings on the floor?

He’d say: ‘Sweep!’

Congratulations, you should be proud! Your DIY router plane design is a real game changer.

One thing that I have noticed in many of your posts is the stunning drawings that you have done. Having a very limited education in mechanical drawing in 7th grade, (the most dreaded thought upon signing up, but part of a four piece program) which I very much enjoyed, and then needing to do a quick sketch in professional life to show an idea or method to make a part, I marvel at your abilities! I know that to practice can mean to process, and your notes showing that you have done quite a bit of practice, but the results compare to professional artists. Some people notice, but I have not seen the respect that you deserve.

I just sat down with a book on technical drawing back in 1966 and took it from there. It wasn’t even a great book but there was enough for me to work out the rest myself. I always liked to draw and 98% of achieving anything is a made-up mind.