Why Crosscut Saws Dominate – Part II

I may not like throwaway saws too much but the reality is they are highly developed and they cut exceedingly well. They are highly prized in the building trades and most plumbers, electricians, plasterers and brickies will have one floating not too far away. Whereas I might not want to take my favourite Disston or Groves into the field for outdoor work as a general rule, I have no hesitation taking out a fine cut Bahco for that type of work. The are highly efficient cross-cutters, cut very smoothly and quickly and actually they do pretty well rip-cutting too. In my guesstimation a Bahco fine tooth handsaw cuts about 20% less efficiently even though it is utterly a fleam-cut tooth pattern designed for crosscutting. That’s a pretty good ratio whether I like throwaway saws or not. And when it comes to sharpness these saws are extremely sharp so watch your jeans when using them.

The fact is that a £12 saw like this fits the modern demand for effective cutting at an affordable cost and that goes for amatuer and professional alike. They may have a tad too much set but they never bind in the cut no matter the material. Disposable throwaways are here to stay in the same way the Stanley utility knife ousted fix-bladed rigid knives of the past. Once a generation loses the skills of sharpening and companies like Nicholson USA chose cheaper downgrading in the quality of their files to sharpen only one saw per file, it becomes financially prohibitive to even own a saw you can sharpen yourself. On top of all that, resharpening services charge £7-10 a pop for their services, so if you use a saw as I do and need to sharpen 3-4 saws once a month or so you had best learn to sharpen a saw yourself pretty quickly or indeed buy into the disposable saw market. Of course you soon begin to see that it is a false economy buying disposable throwaways even in packs of five, but the construction trades have become more highly competitive than ever before. I have yet to meet a modern-day carpenter who can sharpen his own saw and I think he might be thrown off of some job sites if he started filing saw teeth on the job as we did in the 60-70’s.

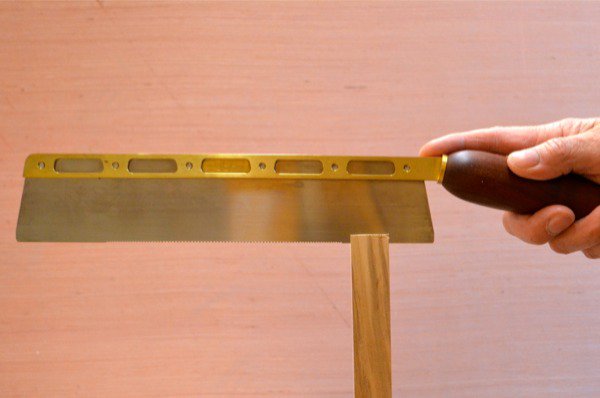

Tomorrow I will talk more on Gent’s saws I think. There’s a lot to these that may not be obvious at a mere glance.

Hi Paul, I read your posts on sharpening (for rip pattern) and will soon be trying to get some old saws back into shape. I very much enjoy the discipline in this and I hope that people will continue to learn the skill, regardless of the extra time it takes. I laughed at the comment about a workman being thrown off a job for taking out time to sharpen these days, so right!

I wondered if you had a post on your blog about sharpening crosscut saws as well though? I have only read the rip instructions, but do you also have instructions on sharpening the cutting bevel on the front of crosscut teeth and the angles involved?

Thanks Paul

best

Gary

I have it written but not posted yet. We are making an updated video and will release both at the same time.

Yes how right you are, about time on the job. I was working for a very high strung, little instigator, as an apprentice carpenter. A journeyman one day was explaining to me the intricacies of cutting coped inside corners of some complex crown moulding we were installing. This little boss told him not to waste time, just get it done! In the mornings he would say “take pride in your work, this looks like crap.” And in the afternoons he would complain we were going too slow and we were the reason he could not afford a new work truck every year. I do not miss him.

No soul when a new truck beats finding fulfilment.

Maybe if he had the truck he could drive far, far away looking for fulfilment.

Hi Paul.

You said at the start “I may not like throwaway saws too much but the reality is they are highly developed and they cut exceedingly well.”

I appreciate the restoration of an old saw, and have really gained confidence from your description of saw sharpening, so much so that I’m in the process of sharpening all my old saws, including a Diston tenon saw inherited from my father. However, for anyone not yet in possession of a suitable saw, I must mention the favourite handsaw I was using before I read your blogs. This has a plastic handle, and hardened teeth, but can nevertheless handle all the bench work you might wish to do, until eventually it goes blunt and has to be discarded. The Axminster FineLine 15 tpi 360mm handsaw. Not a back saw, but with enough stiffness in the blade to do tenons or dovetails equally well. A good first saw until you can afford better! And, it fits in a toolbox.

Ian, I don’t think it’s a quetion of money.

If you go to a flea market, you can get a good saw for 1€, 1$ or else,maybe 2.

It’s more a question of patience.

Are you willing to learn sharpening before using a saw, or do you want to start right now and learn that later.

Both has it’s price.

One is payed in money, one in patience.

Both have their place, it’s your choice,… if you have one.

Back in the dim past, when I began in the trade, we customarily worked five and a half days a week, and Saturday mornings were dedicated to sharpening tools

But what abote the new stanley crosscut saw? Is it good, and can I sharpen it?

Hi Paul,

Firstly thank you for your common sense videos especially the ones about sharpening planes and chisels. They changed my life in the shop.

I`m thinking about purchasing the Glen-Drake saw. Which model do you recommend (teeth size , cross-cut or rip). Its mainly for dovetails in 3/4 pine and some in 3/4 oak. I’m just starting out doing dovetails.

Thanks,

Harry