Are We Obsessing About Sharpening Edge Tools?

I have come to the conclusion that we went through a phase of several decades where people were trained to follow a sort of legality leading to almost obsessing over sharpening without fully realising the criteria we should be perhaps aiming for. As a young apprentice my mentoring craftsman would repeatedly say, “Sharpen up, lad!”, throughout any given day. I dutifully sharpened up on two stones to around 600-grit and got back to task after stropping the burr from the edge on the palm of my hand. My plane never faltered, protested or chattered and the work I did became more and more acceptable through the years. Today I sharpen to higher levels of fineness and encourage others to do the same. That said, I don’t think I am obsessive so much as practical and my practical knowledge comes from my work, not what someone told me or wrote about or showed on a film. My sharpening levels developed through fifty years of sharpening 20-30 times in a day. Evolutionary sharpening has left me knowing my work gets done in a practical way and now it is unlikely that I will change.

We live in a woodworking culture of much head knowledge that has less and less of an application to real life and that might mean real woodworking too. We live in a culture where the shaving has become as much if not more the goal and not the levelled surface or the finished adjustment to the wood being planed. This can lead to a strange and artificial culture that has less a link to working wood as a job or to getting the actual job done in a timely order. My thought is that most people may not be aware that this changes the dynamism of woodworking because they don’t actually work wood for a living but more because they love working wood, using the tools and stretching themselves in spheres of productive craft work that gives them results in seeing something made. My thought though is this. This is all acceptable. There’s nothing wrong with enjoying seeing shavings ripple and rise from the throat of a plane. After fifty years of daily doing this I still enjoy these gifts to my work that are indeed priceless. The point in this article and the ones yet to follow are more to address any imbalanced perceptions people have as a result of magazine articles, catalogue companies and online information that often more distort reality than serves it.

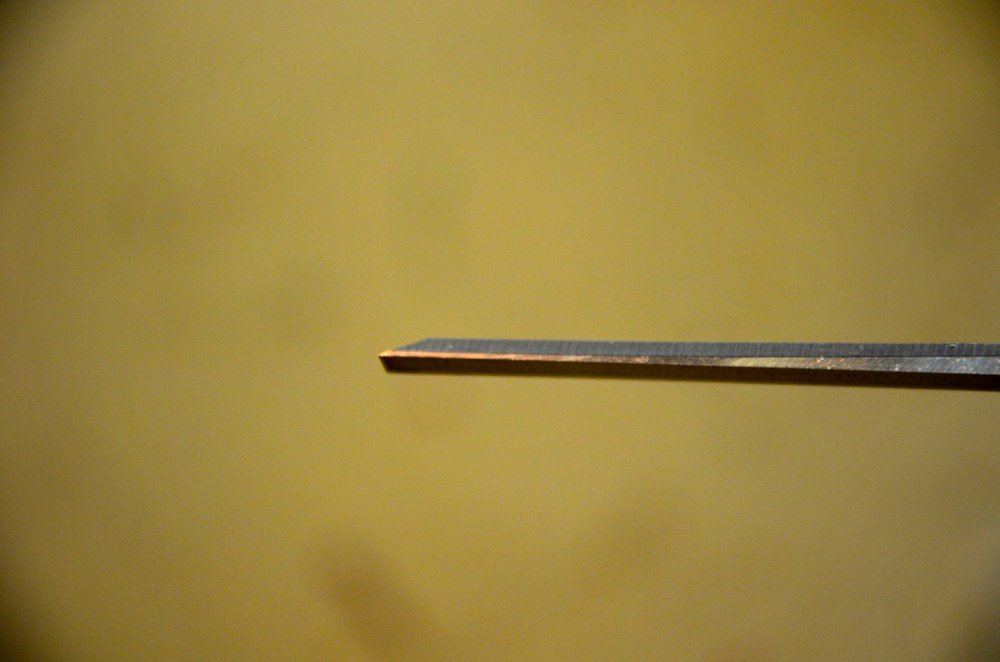

What would you do if I told you that your sharpened edge taken to say 15,000-grit quickly deteriorates in minutes only of use to perhaps the much lower level of under 1,000. The reality is that most woodworkers using hand tools work with chisel and plane edges at this level most of the time. The tools still cut effectively and acceptably for a long time once this level occurs. At this level the edge is strong and degrade speed much diminished. The greatest edge fracture occurs immediately after sharpening when the tool is offered to the wood and the cutting edge is at its thinnest and thereby most fragile.

I have tested new steels and have generally ended up with disappointing results. Someone wrote to me questioning the validity about the Aldi chisels being made from a chrome vanadium steel and said that his chrome vanadium chisels did not take and hold a good edge.

More to come on this shortly.

The two things that have held me up from attempting more woodworking (hand tools or power tools) were that I couldn’t possibly sharpen my tools to the level needed and I would never have enough or good enough tools. Heck even sharpening supplies cost more then I could afford! I didn’t have a magic old tool box full of perfect antique tools. I had old used hand me down junk or Harbor Freight.

Now, I don’t quite feel like I need all that. Maybe I can just sharpen my tools with sandpaper and sheets of glass (or tile). And maybe I’ll just get by with a bunch of Harbor Freight tools and see if I can make something.

I have no goals of becoming a “professional” — I just want to make some things. I want to work wood. I think the magazines and TV shows cater to those that just want to spend money. Or espouse a certain philosophy.

I appreciate your views. I don’t come away feeling like I’ll never be able to do ‘something’ because I don’t have enough tools. I love it when you bring up the Aldi chisels! Gives me hope. BTW, I bought a set of HF chisels. Oh, and I did by one of those nice 35mm gouges from Highland hardware. The “nicest” tool in my collection! 🙂

Dan,

my honing setup was very cheap and inspired by Paul… I have a flat DMT 1200 (eze-lap plate, cheap) and a bench strop loaded with CrOx. I have added an old hand-cranked grinder and a 4 sided DMT bench stone (Lidl, dirt cheap). The grinder is only used for the heavily damaged edges or the harder steels. Most of the time, I get away with the 1200 and the strop. Good sandpaper isn’t cheap here, so the eze-lap made more sense.

With the exception of one metal joiner plane and one wood turning skew, all my tools are ebay or flea market specials that have been restored through this simple setup. As I sharpen free-hand, I don’t need the large (read expensive) surfaces required for honing jigs. It is also very fast… last week I restored both blades on a flea market special dovetail plane in less than 10 minutes. As it is fast, I restore the edge on my chisels as soon as I notice a degradation.

I use a small hand-held belt sander for re-working of chisels, sanding parallel to the edge. Then I finish off with the usual collection of stones. I hold the chisel very close to the tip and only sand for a few seconds before dipping in cold water. It’s really fast. Your fingers tell you when it’s warming up, so you don’t alter the temper.

Not at all a good idea everyone. Belt sanders have dust inside and sparks ignite and smoulder. One shop 30 feet by 60 feet was gone in two hours from a spark this way.

I found out the danger from belt sanders too. It was just a friendly warning puff of smoke and a burning smell . So now I only use the sander for steel . I nearly said metal but aluminium dust makes good fireworks as well . Also the plastic internals that guide the dust towards the vaccuum hole had been partly melted and charred for some time .

Is it not the fact that newly made blades are crumbly for the first few honings as a result of the tempering process? Thus, new chisels will appear to be poor quality until the stronger steel has been honed down to (which the antique chisels would have done years ago). It’s certainly been my experience with Narex chisels that they crumble when new, but become fabulously sharp and long lasting after a few rounds of sharpening.

Alex – that’s my experience, too. Not with Aldi chisels, or with Narex, but with another of the ‘high end’ British manufacturers that Paul doesn’t name.

The manufacturing process (both heat treatment and subsequent grinding) does affect the steel where it’s thin near the cutting edge (it did with vintage chisels, too, when they were new). Once that’s honed away, and you’re into the ‘good stuff’, then edge taking and edge retention are fine, and the equal of vintage chisels. That’s my experience with Ashley Iles chisels, anyway.

Wish we could find them in the U.S. I strive to use only what you recommend.

How on earth can you mess up something as simple as a wood chisel? You have to make a special effort. It can’t be done by accident.

Seems like progress by fail. A while back I ordered a hot fudge sundae at a local restaurant. When I began to eat it, it tasted wrong, I waived down the waitress and ask about the sundae. Turns out they used soft serve Ice cream, chocolate flavored corn syrup and “whipped topping” from a bag. It was disgusting. The restaurants idea of serving their customer was to use garbage instead of real ingredients and in the process they ruined a simple and delicious desert. In much the same way tool companies foul up otherwise simple things like wood chisels by over thinking and under achieving.

Think about this scenario. So I call Frank down at International Industrial Supply and I say Hey Frank I am gonna make some chisels, send me a boxcar of wood and a boxcar of steel. So Frank says, if your making chisels you want our tool steel right? And I say yeah, tool steel. Then Frank says, okay Terry, 1 boxcar of each, they’re on their way. So I say, thanks Frank, checks in the mail. There ya go, I have just outperformed most major tool manufacturers operating today.

THERE ARE ONLY TWO INGREDIENTS IN A WOOD CHISEL! WOOD AND STEEL! HOW HARD IS THAT?

Improper quality controls (or lack thereof) and processes designed by accountants are two major causes in my experience.

Tool steel is only as good as the heat treatment and tempering it received. It has been my experience that companies will always find a way to mess up a process, no matter how simple and fool-proof it is. Companies see an economic advantage in cutting corners, which is why quality control is required. At the same time, quality control is largely seen as an expense… so companies tend to cut corners on the measures put in place to avoid cutting corners.

When I was still working in industry, the official policy to source components was to always select the cheapest option that matched the specs. Even if the difference was literally a penny per million items and the “more expensive” option had better quality controls in place. The company repeatedly ordered parts from India instead of a supplier that was literally 30 km away from our plant. The Indian supplier quality control wasn’t as good as the local one so the pennies “saved” created costly issues, and yet… at every round, the purchasing department made the same choice.

Basically the quality of the end product is likely to be only as good as the weakest point of your supply chain and processes designed by accountants tend to weaken the supply chain.

This is why British industry continues to decline and Muppet governance motivated only be self interest, social staus, financial power and so on continue to destroy a world that would otherwise work for us.

I don’t know anything about British politics but sounds like it is similar to what’s going on here in the US. I’ve seen you use the term “Muppet governance” before and I think it’s spot on. Good thing we are wood workers or we’d be less polite.

The reduction in quality is also a reflection of what we as customers are prepared to pay to get what we want and how immediately we want something. Businesses exist to make money, a simple truth we often forget and will always sell what customers are prepared to buy. Companies such as Bad Axe works will continue to thrive an prosper provided they continue to offer quality products at a price that enough people can afford to buy them – if people stop buying their tools in sufficient quantities they either stop making them or find ways to make them cheaper to increase the number of sales.

Unfortunately many people in our society today wants to own something of everything, not saying if this is wrong our right but each of us only has so much money to spend. To feed the need of owning these items we demand the items are offered at lower and lower prices – we never stop to think of the consequences of this. Paul has written many times about the quality of older tools and I agree with him on this – but what if we think about what these tools cost the original purchaser in terms of hours worked to earn the money to buy them. I started buying tools in 1972 and I remember tools as being expensive in terms of money and hours to earn them and everyone paid cash – no instant gratification. The local joiner used to go to jobs at people’s houses with his bass hanging on the handles of his bicycle. All his tools were in his bass or his chest. Tools were expensive and we demanded and got what we expected. Tools were also only available at a few retailers open for what by today’s standards were very limited hours. This changed rapidly in the mid seventies paving the way to where we are today.

Have we moved forward? Each of you will have your own opinion.

In other words the majority of people will get what the majority of people value.

Ah, but why just criticize the producers of tools (or anything really!). Isn’t it so that the consumer that salivates over a few pounds discount gets what it deserves – cheap in price and cheap in quality. The producers could claim that they are really only giving the market what they want. The problem is when the producers who are producing good quality go broke or simply follow the rest of the pack to the lowest common denominator – the discerning consumer then finds that they cannot purchase any products of quality.

It’s both the consumer and the manufacturer and of course the selling medium through which they operate. It’s not just that we want to save our money, but that often we, the majority, don’t have it.

I think that this is a valid comment and thank you for it. Your’e right in mentioning consumerism, consumerists and the consumerist mentality. What is most amazing about the chisels here is this one thing: the chrome vanadium chisels from Aldi tested best in out tests alongside three major high-end makers from the UK and North America. These chisels are indeed very inexpensive, about the cheapest money can but in terms of cost, but certainly not cheap quality at all, nor a compromise in terms of value. What are the profit margins on high end chisels? Are we snobs when it comes to chisels? Are we preferring makers for their price, looks, quality or value? All questions. I certainly far from feel inferior using a £2 Aldi chisel. There could be other moral issues that I know nothing of, but that’s been the same for Irwin Marples and many others. Where are high-end makers sourcing their steel from, having their tools or tool parts made. We really don’t know any more. The Aldi chisels are slim, balanced, strong, durable and lifetime. That’s all I ask of a chisel.

Paul

Bought a set of Aldi today after much dithering, dont need them as I still have my chisels from my apprenticeship in 1960, Ward, Mawhood, Marples, Hildick..

I just wanted to see if they are up to scratch, and I totally agree with you well ground and nicely finished, I could fit London pattern handles but they would not cut any better.

Sharpening, there are those out there who have lost sight of the fact that you sharpen up to get on with the job.

When you and I were apprentices we probably had a couple of Norton India stones maybe a piece of slate or if you could afford it Washita or Arkansas stones.

We had never heard of 15.000 grit and scary sharp, just sharpen up and get on with it lad!

I do agree with you that we needed to move on from 600 grit, and I have done so, but it is a means to an end not some obsession to see my refection on the back of the blade.

Keep up the good work.

Best wishes

Fred Sutton

Hello Fred, well I have done more testing and they are more than just adequate. My tests show that the steel is up with the best.

Paul, I’m very curious about who makes these Aldi’s chisels for Aldi’s. Obviously Aldis doesn’t have a chisel factory somewhere churning out chisels for the stores, they just brand someone else’s chisels. Our mystery chisel manufacturer is doing a fine job and perhaps deserves some credit and perhaps some direct business to encourage quality work. Any indication on the packaging (I’m across the pond or I’d look for myself)?

Hi.

On the back of the packaging it says made in China.

It is easy to be dismisive of Chinese goods, but first take a look at Quangsheng planes.

Maybe Aldi have set a high spec and good quality control.

.

Regards.

Fred Sutton.

The Aldi chisels bought recently (Oct ’14) have the following etched on the back: Saphir Handelsgesellschaft mbH & Co.KG Domstr. 19, Hamburg, Germany, Model: SH-SBS-1

all widths have the same model code. Coincidentalky, they are similar to, but slightly better finished, some chisels I bought 4 years ago from Lidl (C-V chisel with ash handles of same pattern) No made in China on packaging on either.

I have exchanged a couple of e mails with Aldi customer services and they confirm that the chisels are made in China as are all Workzone tools.

The narrative on the back of the chisels (when translated) refers to the German trading co i.e. importer

Should you wish to verify my statement contact Hannah Alton. Aldi UK 0800-042-0800

All of this changes nothing the chisels are excellent value for money and up there with high end UK and EU manufacturers.

If you were to take some of the extra O-1 steel from making plane blades and followed the same process, you could have a nice set of chisels. Paul did a free extra video on making chisel handles.

A combination of dumbing down our society (“smart” phone generation) and Planned Obsolescence is what brought us to where we are today.

Very few people today stop to think, does tecnology and acquiring more and more goods, in an never ending cycle, realy makes us happier people. I think not.

Long live Aldi chisles 🙂

Could it be of the same manufacturer as Aldi’s?

I started wood working with my grandfather back in the ’50s and ’60s when he had nothing more than a whet stone and a file. He did some nice work. I also learned more in Wood Shop during high school where we had, guess what?, whet stones and files. My father would sharpen his pocket knife on a whet stone and perform “surgery” on bull calves as well as any vet. I look at furniture made 200-300 years ago that have awesome joints and finishes that were made with tools that never saw a diamond hone, or 15000 grit anything and think those guys did it, why can’t we? I sharpen to around 1000 then strop on leather with polishing grit. Every tool will shave the hair off my arm and curl wood so thin you can see through it, and I don’t spend a lot of time doing it.

Not really sure what the point in this is???

My Lidl chisels that look exactly like aldis don’t hold the first sharp edge I’ve made. It actually started crumbling withing half an hour of cutting dovetails in cedar. I didn’t expect that at all. I hope its like someone posted in here, that I will have to remove brittle steel and get to the proper steel after few sharpenings. I don’t expect anything and would not be too sad to throw them away if they can’t keep the edge after some time, as I really don’t see the use they can have, if all they need to do is to be sharp for long enough.

I suspect it is that the initial sharpening is removing the brittle steel because I have had both types and many a dozen not just a few and they have been just about the only consistent economy level chisels that have really proven their worth (having used ten sets since 2010 to date without a single issue plus many trialed sets too.). I now use them in the everyday work I do and prefer them over many a high-dollar one I own. That said, you really cannot lose because if they are faulty they will give you your money back without question.

Here is a vote for my cheap and nasty chisel with the word Foreign stamped on it. It does all those awful scraping jobs where plaster and bricks are near the wood . It saves the sharp ones from damage. I don`t bother to sharpen it though . I think one of the features of the Aldi chisels must be the way they heat treat the metal . The Germans have devised a complicated and precise cooling and reheating process to grow the (martensite ? )crystals in the metal . It`s very scientific and worth reading about .

I have started sharpening my multitool Bosch blades with a cheap and small diamond file from Poundland . The one inch wide blade is used to open a section of floorboards without marking the plank next to it . My boards are thick and very hard . I never got on with floorboard handsaws.