Custom Sharpening – Bevel-ups and Jack Planes

Question:

Hi Paul,

I recently bought a LA jack plane from LV and I was wondering something : would you sharpen the bevel of your BU plane like your BD plane ? I’ve search on the internet and I even watched all your videos on sharpening + your DVD. I didn’t find what we could call a definitive answer. Can I use the convex bevel technique ? How much camber do you need more on the BU plane ? Do I really need more camber on the BU plane ? Could you please enlighten me a little more on sharpening BU plane iron.

Thank you,

Jeremie

Answer:

Well, in my experience, using the LV planes and other makes over several years now, makes me ever conscious that woodworkers often look for additional planes to somehow cope with what our present arsenal of planes might seem ill-equipped to handle. Surprisingly, and you might be glad to hear this, the fact is some woods will not plane well no matter the plane used, the iron used or the skill of the worker. Sharpness is of course always the most key element and especially is this so with BU planes. I say that to say it’s not necessarily the pitch of the blade the presentation of the bevel up or down or any other such thing although either plane can work better over the other in certain circumstances. With so much information out there coming from “experts in the field” and novices alike it is indeed difficult to know what’s essential, what’s preference alone and what biases are out there that have little or no foundation beyond just one person’s opinion. Our modern day versions are of course nothing new except to claim better engineering standards with some innovative addition as a sort of copyright quirk. Replicated #62 planes are now available as import copycat knockoffs from Asia via the Woodcraft’s Woodriver version, Quang Sheng or Amazon and eBay selling Stanley’s own current version of their old plane or Lie Nielsen in the USA. Only Lie Nielsen is domestically made to the USA. All others are imports from Asian makers who have by the way upped the anti in terms of quality I must say. I suppose it’s true to say that they either all copied the original or one another or they are made in the same factory somewhere. Only the LV is original as an original design I believe. One day we will see true innovation in plane making that creates affordable functional working working models again but as they say in Texas, “If it ain’t broke don’t fixit.” Oh, I think you can also choose to buy an old and original model #62 for a hefty sum more than the newer versions, but I am sure whichever you choose you will fare well.

There are of course issues with all of the planes and when you run them side by side you see them, but sharpen them up well, adjust them accurately and such, and you may not find one any better than the other.

There may well be differences between irons you will need to know about as different irons are made from different steels, Hard, softer, harder. I suggest that go with the O1 steel cutting irons as they need less sharpening and take a good edge. With the O1 steel plane irons you sharpen them exactly the same in general as you would a standard Stanley or Record bevel-down iron. Same bevel angle, everything. That’s if you are in fact using the O1 blades and not say A2 steel irons which are harder and more brittle. On A2 irons I suggest a steeper pitch of around 35-degrees as a minimum as the edges fracture more readily and even at that they will need more frequent work and lots of it to reestablish the cutting edge.

Reading between the lines becomes ever important when considering plane makers. Most if not all of the bevel-up low-angle plane makers, sellers and so on currently producing and or selling BU planes will write in their promotions stating the plane irons are ground and polished out at 25-degrees primarily to prove that the planes present the lowered bevel cutting edge at a the lower angle than the bench planes with bevel down irons installed, which are generally bedded on a regular bed of 44-degrees. This really isn’t altogether true. They state that the combined angle will be 12-degrees for the bed and 25-degrees for the iron and so total the two out as a presentation of 37-degrees. In reality the cutting edge is quite weak and you’d be better off grinding and polishing out at at least 30-degrees on an O1 blade and the very least 35- degrees for A2 blades.

Looking at our recent findings in more at-the-real-bench work this could all be thrown out because we realise more and more that both sides of the cutting edge do indeed fracture and cause even higher angles and this is a problem on bevel up planes because edge fracture on the under face, the larger flat face, means the blade soon starts to ride the bevel of the blade as the edge fracture moves from a presentable angle to the point (or the edge) where the actual edge can no longer reach the wood. This then means many more frequent sharpenings than the conventional bevel-down planes. On a controversial element, I find only minimal differences between bevel up and bevel down planes when it comes to working the planes and when I take the planes to the wood, regardless of thick and thin irons, BU or BD, both planes seem quite parallel in cut quality and ease. If there is a difference in favour of BU planes then it’s indiscernible to me.

Below shows the camber I like on all my plane irons. This method has proven to serve best for and was the preferred method used for centuries by craftsmen.

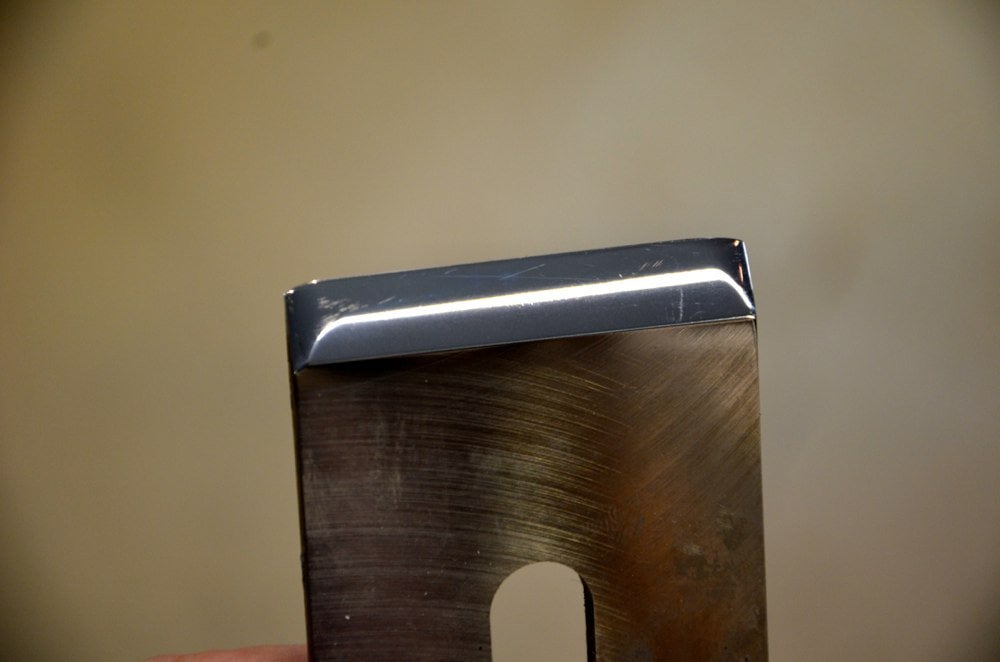

Above images show the bevel and flat faces of the LV iron showing rounded corner edges.

At the end of the day then, bevel-up, bevel-down is a matter of preference for a particular task. I like using both plane types and enjoy the luxury of choice. If I ever had to choose one plane it would always be the bevel down plane, but that doesn’t mean the BU planes have no place. Indeed they do and they are of great value.

Above you see thin and thicker irons side by side with the corners rounded to prevent any step down on wider boards.

The BU plane iron meets the same demands as the bevel down and you should treat the iron the same way after determining the pitch of the bevel in relation to the steel type if you so decide to change it. That is the corner can be rounded slightly to eliminate tram lines ion the surface when planing boards wider than the iron. If you only intend to use the plane on a shooting board which i cannot imagine why you would unless thats all the work type you do then keep the corners square. You can also camber the iron slightly along the length or width of the cutting iron for pure smoothing if you want to. One sales outlet describes the Quangsheng BU jack plane as the “Swiss Army knife of planes”, I suppose because they offer three cutting irons with the plane sharpened at different bevel pitches. Not sure if that meets the same criteria really, but I like the humour.

After getting into hand tools, I bought probably 2-3 of every numbered Stanley on the market because I thought that’s what you needed. I learned to restore them, sharpen them, and use them, but in the end, I sold every single one off except my Stanley 4 1/2, LV BU jack, smoother, and jointer plane. I have 3 blades, the original 25 degree, probably closer to 30-35 degrees now, a 38 degree, and 50 degree. They swap between all three planes with ease. Easy to set up, sharpen, adjust, and with those three blades I can plane just about any wood with minimal tearout. I found they work incredibly well for me as a set. I’m going to purchase the LV BU smoothing plane with the square sides and smaller blade next time they have free shipping because id love to have a slightly smaller plane other than the BU jack with square sides for shooting and doing small tasks. But these work great. I reach for the BU jack and large smoother first before any others.

Great post as usual! You’ve articulated a few points that I think I had only become half consciously aware of. Only now am I realizing that it does need sharpening more often than my bevel down planes.

I’ve never regretted the purchase of my Veritas Low Angle Jack. As a Canadian, it felt good to support a company that produces such well made tools. As a beginner, it was great to have a plane that performed well out of the box, since previously I’d been tuning up wooden stock planes with varying degrees of success. It’s a great size for legs and rails. Fantastic shooting plane. I used it a lot on my first projects and was really happy, except for the fact that it seemed to lift slivers of wood out of white pine. Honing to a higher angle seemed to stop that from happening but made the plane a bit harder to push…which is where the plane runs into trouble. It’s just not very good for flattening wide, rough hardwoods. If you’re building something the size of a chest of drawers out of solid walnut, the blade can’t be cambered enough to be used across the grain like a scrub or try plane. They sell a toothed blade but I found it was too tiring to push for very long. I fell back on the Stanley #5 with a heavy camber and found that perfect. Even on softwoods now, I find I’m using the LA Jack less and less as I work faster with a #5 for rough sizing and a #4 with a closely set chipbreaker for polishing up. Light nimble planes.

One job where the LA Jack remains indispensable to me is when it’s used with a high angle blade for edge jointing stuff like curly walnut (because any amount of tearout will ruin your joint).

I too discovered that the A2 is brittle especially when shooting but what are your thoughts on PM-V irons they say it holds an edge for much longer than 01 and A2.

I cant validate this steel as I haven’t tried it, but I do know Veritas and they are an excellent and responsible company.

I’ve been contemplating whether or not I should spend the extra on that blade this is one of the reasons why I wanted to use the low angle jack as a dedicated shooting plane and buy a 5 1/2 as my grunt. Maybe this way I’ll spend less time sharpening and more time working.

This is years later, but to make any bevel up plane last longer on the edge without affecting the cutting angle put a back bevel on it less than the frog’s angle, but as close to the frog’s angle as you can, this will make the edge of the blade more stout so it will not chip as easy.

Thank you Paul for this interesting post. My question relates to the chip-breaker as it relates to the BU/BD debate. On the one hand, the edge of the blade as it is seen from the wood is pretty much the same in both cases. Assume a 30 degree sharpening angle for both. For the BU plane, the lower part of the blade is at a 12 degree angle from the wood surface and the upper part is at 42 degrees (bed + sharpening angle). For the BD plane the upper part of the blade is at 45 (parallel to a standard frog) and the lower part is at 15 degrees (frog – sharpening angle). Thus the BU plane presents 12/42 to the wood while the BD plane presents 15/45 — not a huge difference. Now, why should we insist on a chip-breaker on the BD plane while the BU does not have one and does not seem to miss it?! (the question remains the same with a BU + 40 degree sharpening vs a BD with a 55 degree frog…).

The physics of the centre of thrust are indeed not so different in that the centre of thrust which is the centre split of the 30-degree bevel presented at 12 degrees is 12 degrees plus half the 30-degrees so 27-degrees on the BU plane. The centre of thrust in the BD plane presents the blade at 44-degrees and minus 15-degrees so presents at 29-degrees. That said, the thick mass at the cutting edge with direct mass behind the iron and no calculable gap means a rigid inflexibility that does impact the wood differently. Now I suppose my concern is that some people are saying the BU plane is like a miracle plane and that is far far from true. `they do present the BU plane as a plane that tackles any and all grains and that simply isn’t true either, not without taking the prep work to the ‘enth degree. For a hobby or a pastime this is fine, but when you want to be a serious woodworker getting on with 98% percent of real work that needs no BU plane for the work at all, it’s highly impractical. In my view it should be the scraper that should be heightened in popularity and not the BU plane but there’s a limit on what you can charge for a Scraper #80 whereas a plane that’s touted to tackle all grain and looks good to boot the sky is the limit.

The chip breaker is only a chip breaker in the US. Some say this is semantics, but the cap iron is a strategy developed further by Leonard Bailey whereby two counterpoised pieces of steel come together in contention with one another in a common cause, to counter the very thing thick ironed heavy plane makers say is a flaw in thin ironed planes. A flaw by the way that they say results in chatter. This is another point of view really. Thin irons with cap irons fitted and tensioned properly are an intentional dynamic as is the case with older thicker irons and cap irons.

Many old and thick ironed planes had cap irons on them too as we all know. Why, well it was the same strategy. To absorb stress and indeed to divert the shavings more abruptly upwards. This is why, for the main part, the bevel down will tackle about 90% more work types than bevel-up planes and why in the realms of real woodworking we reach for a bevel down plane and not generally a bevel up. Many espouse BU planes for dominant use saying that BU planes do everything and more than BD planes, but I have far from found that to be the case. I find BU planes have so far proven to be more high maintenance planes than bevel down planes for a number of reasons.

Can I ask did you round those corners off either with a file or grinder or just purely on the stones. I’ve always had issues with this, I have rounded my corners on a stone by presenting the blade 90° on the stone but still to this day I get plane tracks. To give you a more cleaar picture of what it looks like 95% of the blade is straight there really is no camber but the corners have been taken off by rounding them.

The rounded corners follow the same bevel as the bevel itself so it is more a question of lifting the iron in the same plane as the bevel about 3mm (1/8″) off the stone and rubbing maybe 20 times to form the angle and then lowering it with subsequent strokes to form the rounded corner. Do the same on the finer stones and then the strop and that’s what you end up with.

Thank you Paul I will be doing this first thing in the morning, also I am now convinced on your method of no secondary bevels. I have spent an entire day establishing primary bevels of 25° just to get rid of the secondary bevels which were at 35-37° in order to reestablish them. Had I had a single primary bevel of 30° or higher I wouldn’t of spent an entire day sharpening all my blades, maybe 30 mins tops. So how come they claim it takes longer to sharpen an entire bevel when in reality it takes bloody forever to get rid of the secondary bevel because of the two major angle difference.

Thanks for sharing your knowledge Paul. I noticed that in the top picture you have your index finger extended. I’ve always associated this technique with bevel down planes because I’ve only seen it used with those types of planes. The Veritas video on YouTube showing how to set up and use a bevel up plane shows all fingers gripping the tote which is how I use by bevel up Jack plane.

Do you extend your index finger as a result of it being a habit engrained through years of using bevel down planes or is there some other reason? Have you observed a benefit from doing so as opposed to clasping the tote with all fingers?

Thanks

Veritas and all the other makers of this type of plane missed the significance of the pointing index finger for obvious reasons. The pointing finger creates a dynamic in the hand that helps align the plane vertically and add sensitivity to the hand in guiding and aligning the plane to level. I chose the Veritas because I can rest my forefinger fingertip on the setscrew. It would have been nice if the screw were 6mm taller with a slight cove to the corner but it still just about works for me as is. Full fist grips on any tote or handle means a loss of sensitivity generally I find and the older I get the more I seem inclined to refine my working ways.

Thanks Paul. I will give it a try on the weekend and see how I go.

Hi Paul

With due respect for your years of experience, some of the comments you make about BU and BD planes, their blades and set up would be severely disputed by many woodworkers. Responses to your comments would include:

1. There are differences between BU and BD planes that will be masked if all you do is use them with blades that have the same bevel angle. Even when used with the same cutting angle, the planes have different potential.

2. A (12 degree bed) BU plane used with a 25 degree bevel (for a 37 degree included angle) will produce a smoother finish and cut more easily on end grain than a common angle (45 degree) BD plane. Consequently, a BU jack will make a better shooting plane than a BD jack. And, yes, many woodworkers actually do use them this way. Further, A2 steel is not brittle and works very well at 25 degrees in a BU plane. I (and many others) have happily used an A2 blade in a LA Jack for many years without any issues.

3. By contrast, the same BU plane with 25 degree blade used to smooth interlocked face grain would do a terrible job! The 37 degree included angle is far too low, and creates a Type 1 chip, that is, one that splits far ahead of the blade.

4. One of the advantages of BU planes is that it is easy to use a blade with a high angle (such as 50 degrees) to prevent tearout on interlocked grain since these create a Type II chip. I have much experience of this with Australian hardwoods. I note that you do not include this in either your repertoire or recommendations to others. It is not the only way to deal with interlocked grain – there are others.

5. Another way is to use a BD plane with a chip breaker (or cap iron) set closely to the edge of the bevel (in the region of .3 or .4mm). This is quite easy in practice, and very effective in controlling tearout. You seem to enjoy poking fun at both methods, which puzzles me. The chip breaker does not only function to stiffen a thin blade and dampen chatter. The chip breaker may be easily demonstrated to control tearout on the thicker blades of BD planes, such as those from Lee Valley and Lie-Nielsen.

I look forward to your reply.

Regards from Perth

Derek Cohen

Derek I know I am not in your league as you are very well known and respected to us Australian woodworkers and I’m embarrassed to even contradict you but on this occassion I feel I must. In regards to point no.2 I must say I have not experienced what you say, at that recommended angle I have experienced difficulties in consistant shooting even after putting a freshly sharpened blade to the end grain. It would reach a point to where it would just glide over the end grain without taking a single shaving. I’ve experienced this more with pine than any other timber, I’ve been advised by Deneb from LN to make the scondary bevel 35°, upon doing so I have not had an issue of shooting pine or any other timber be it softwoods or hardwoods.

The other point I would like to add is I too found the A2 to be brittle, many of times my edge has chipped in shooting but having said that I have only experrienced this prior to changing the angle of my secondary bevel which now leads me to my third point of why I even need a secondary bevel at all. I have experienced much hardship taking out the secondary bevel in order to reestablish my primary bevel of 25° when I could simply do what Paul does and have one single primary bevel of 35° quickly sharpen it and get on with the job.