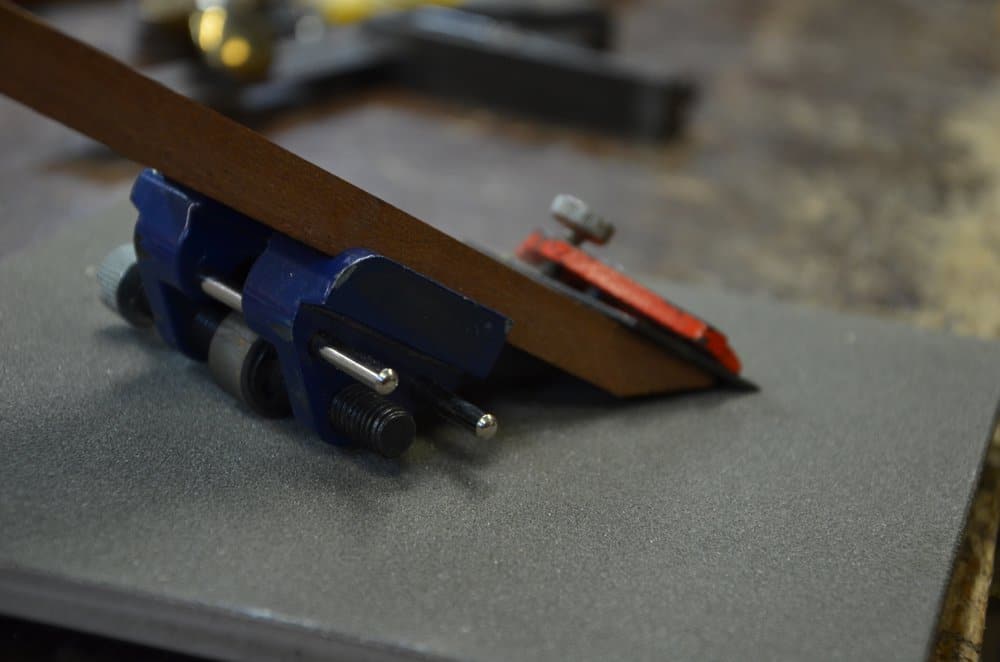

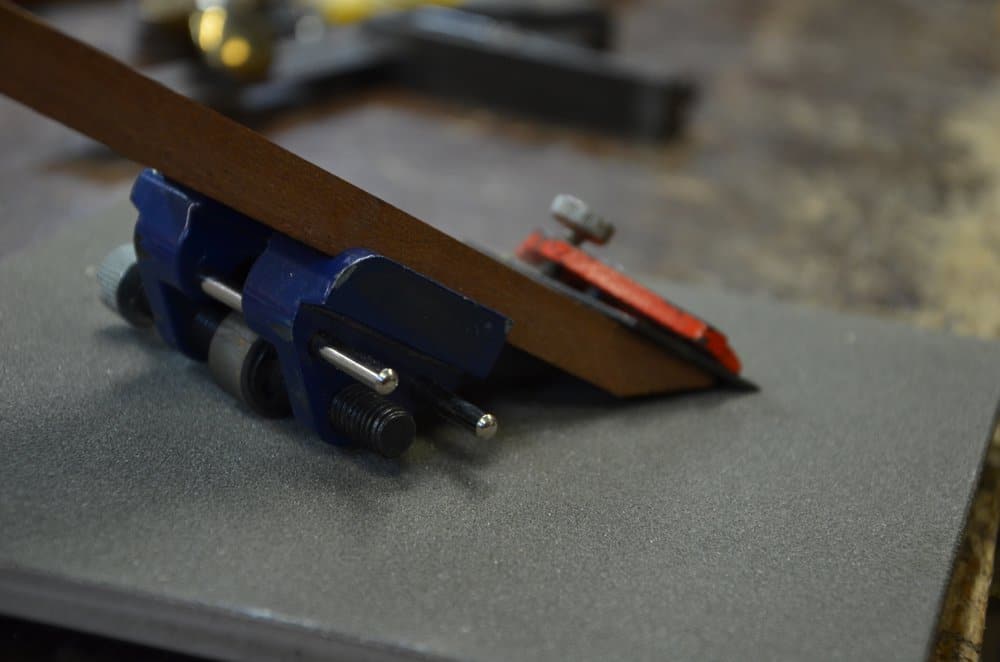

Spokeshave blade extender to sharpen on YouTube now

For more information on spokeshaves, see our beginner site Common Woodworking.

Hope you enjoy it.

For more information on spokeshaves, see our beginner site Common Woodworking.

Hope you enjoy it.

Comments are closed.

You must enter certain information to submit the form on this page. We take the handling of personal information seriously and appreciate your trust in us. Our Privacy Policy sets out important information about us and how we use and protect your personal data and it also explains your legal rights in respect of it. Please click here to read it before you provide any information on this form.

This is awesome, thank you for posting! I was thinking of buying a pre-made jig from online, but this looks like a fun little project.

As usual a simple solution to a bit of a sticky problem. One other question – I hear you say that the blade as is could be used in a round bottom or flat bottom spoke shave. But you also mentioned that the heal of the bevel can interfere with the cut – I have a round bottom shave that chatters and I am going to look to see if the heal of the bevel is interfering with a clean cut – or perhaps you have other suggestions? My 155 performs flawlessly – but the round bottom chatters like a 6 year old at a swimming hole in May!

Blade chatter is really more rare than people think and many woodworkers attribute interruptive surface cutting as chatter when it’s actually the whole spokeshave body and all skipping or skudding causing the interruptive surface pattern through interruptive cuts. That’s not blade bending at all, which is what chatter is. Chatter is an iterative flex of such minute interruption is leaves a super narrow band of surface marks a mere 1mm or less apart in the surface. I’m not saying it never is, but most often not. This skipping and skudding interruption is especially common with spokeshaves and in particular round bottomed versions, no matter the maker. Spokeshaves benefit from dead 30-degree bevels that are flat, not convex or concave, and being polished out dead flat too; at the same 30-degrees. So strop in the holder extender without lifting up at the end of each stroke. Also, with spokeshaves like this, consider sharpening only to 1200 and not stropping at all. This works very well too, surprisingly. I have found friction on the sole is a major contributor to staggered surface markings like chatter. Use light machine oil or candle wax to the sole and this usually cures any such problems. Also, the 151 round-bottomed is totally intolerant of too much blade protrusion. It only ever works well with thin shavings. I use my flat bottomed for most concave work until I get a tight curve and then I use the round-bottomed.

Excellent video.

I’ve made one of those Veritas kit spokeshaves with a tiny little blade. I’m thinking that the screw holes can be used to mount it to the sharpening extender.