Sharpening traditional spokeshaves

For more information on spokeshaves, see our beginner site Common Woodworking.

Question:

How do I sharpen my wooden spokeshave, Paul?

I have a wooden spokeshave and want to use it but with the two prongs sticking up I can’t really work out how to sharpen it. How do you sharpen yours?

Answer:

This question drops through my letterbox often enough to need an answer and the answer to it is really very simple. This spokeshave is quite different to the all metal cast spokeshaves but you can also use this method for those too.

The shaping of the blacksmithed spokeshave is radically different than modern ones because the blade aspect has a relief in the underside that forms the sole of what is effectively a side-handled plane and the top edge also has a deep relief too. This is not always the case as some of the spokeshave blades have had these features abraded out of them or were made without them. The sharpening issues are the same however. Relieving the back or bevel edge of the spokeshave blade eased the work of the user and meant he had only 1/3rd or less of steel to remove when sharpening. The relief to the flat face or underside of the iron meant a much more effective cut. If spokeshaves don’t have this feature then the front edge of the spokeshave itself has a relief that allows the spokeshave to tilt and so provide relief that way. As I said, both methods work just fine.

Remove the cutting iron by tapping the tops of the tangs equally and without straining them too much against the wood.

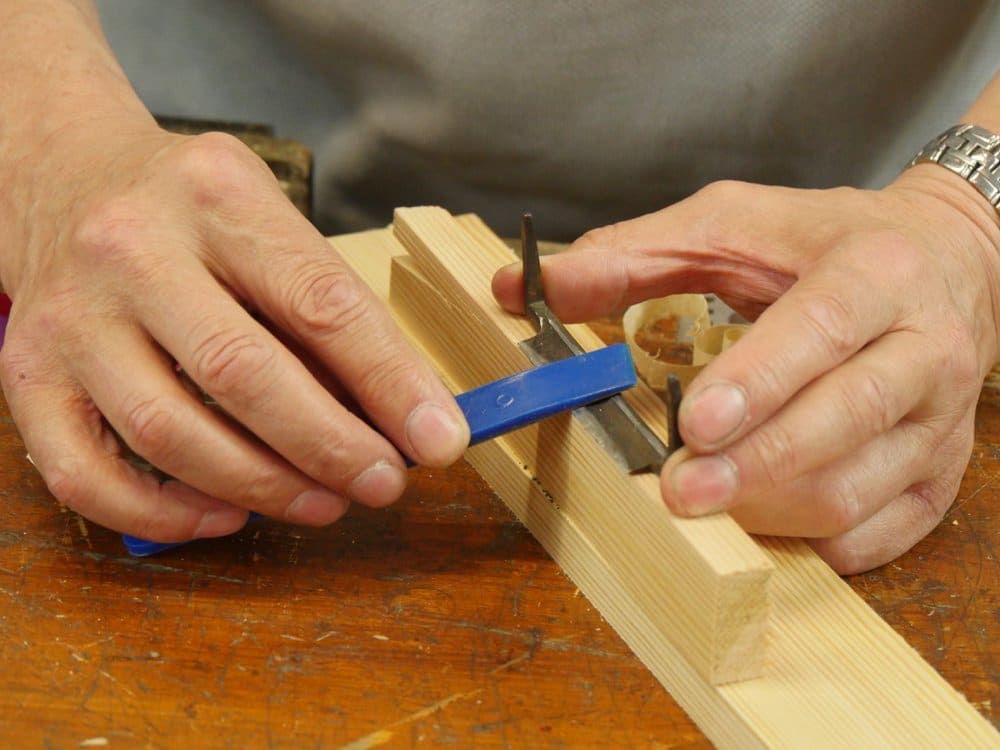

To establish the bevel angle jack the blade up onto a block or blocks as shown. Notice the end of the hone registers to the workbench top for the semi-fixed angle. By moving the paddle sharpener called a diamond hone in or out you can match the angle exactly. You are shooting for 25-30-degrees, but often you can just follow the existing angle unless it is way to steep or shallow. If it is too steep you can abrade the back edge of the bevel with coarse sandpaper glued to a paddle of wood. If it’s too shallow you can establish a new bevel of 25-30-degrees quite quickly and it need not be very wide at all. 2mm is plenty. Gradually, through subsequent sharpenings, the whole bevel will be abraded bit there is no advantage to doing that early.

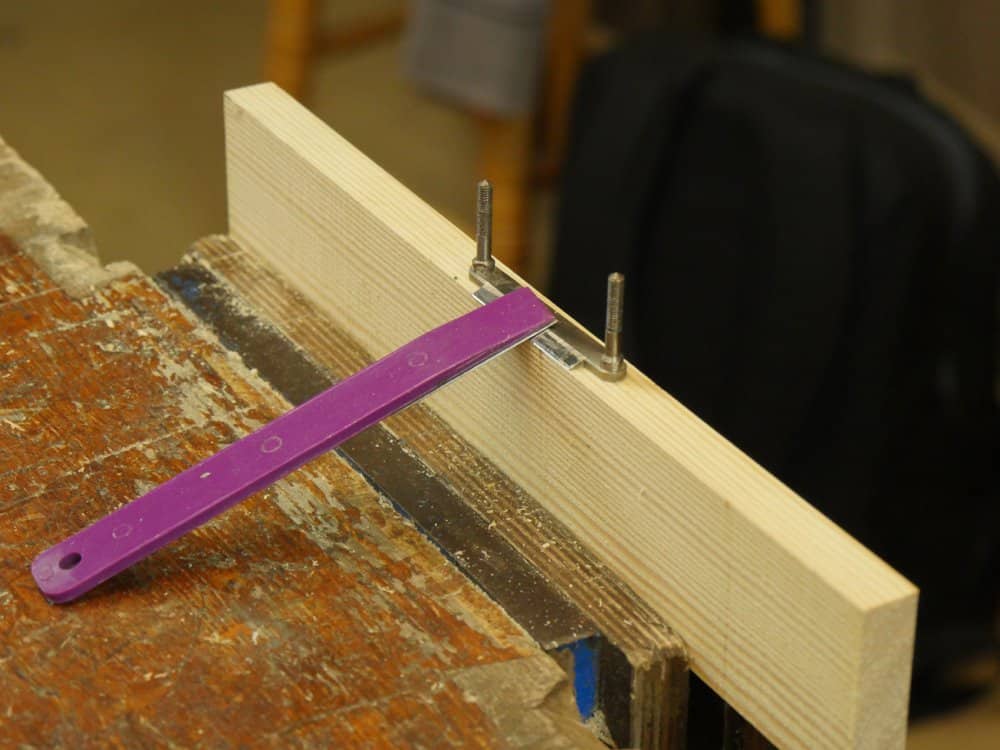

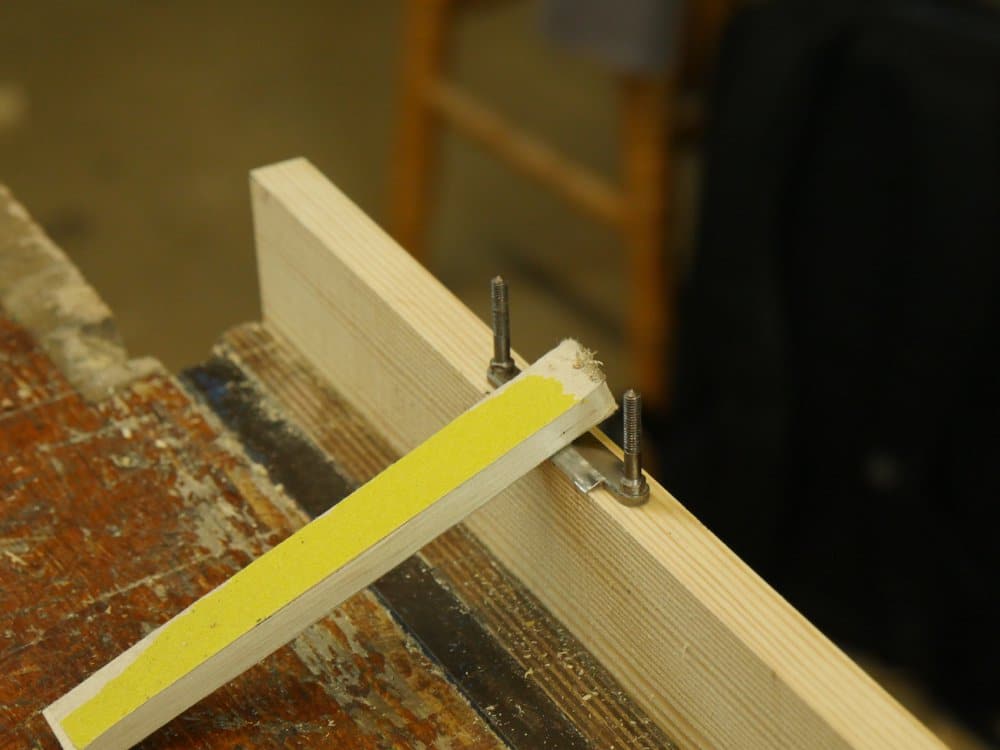

I am using EZE-Lap diamond hones in coarse (purple), fine (red) and superfine (blue) grits. If cost or availability is an issue you can use sandpaper adhered to a wooden paddle. The diamond hones work exceptionally well for this as they remove steel fast and they last for hundreds of sharpenings too.

With the cutting iron at the right height I move the hone in elongated elliptical rotations to abrade at the first level until I feel a small burr to the opposite side of the cutter on the flat face edge.

I change abrasive to the finer level and repeat the procedure without altering the angle at all. This polishes out the bevel further.

On the finest diamond hone I remove the mid-level striations to more polish out the surface and this means I am ready for the last level, which abrasive compound charged to a flat stick.

I charge the flat face of the stick of wood with chromium oxide buffing compound. This is not absolutely necessary because the spokeshave will work at this level. But it is so little extra to do this it’s worth doing.

Pushing only polishes the bevel perfectly and gives me the ultimate edge.

I have already done the same to the wider surface on the reverse in previous honings and of course with wood being abrasive the face rarely needs any more work after the original initialising process.

I use the same paddle to work the flat face just enough to release the wire edge.

I use the same system for my Veritas (and others of this type) cutting iron too. This saves me removing the threaded tangs and makes the process effective and fast.

Everything else is the same as above, except…

…here, instead of blocking up, I am using the vise to hold my platform to the right height instead of blocking up to height.

Oh, and remember to use paddles with abrasive paper of you don’t have access to diamond hones.

Tomorrow we can install and set the cutting iron.

I noticed the blade of the example spokeshave is flat, but I recently picked up a very similar too, only with a slight curve to the blade. At first I though perhaps it was just bent or mis-sharpened. but when I compared it to the brass sole plate, the two match perfectly.

I’m new to woodworking . . . and while I’ve had a good basic Mora drawknife for some time, this is my first spokeshave . . . . and rather than rely on my usual Experimental Method (with variable results) I thought I’d ask an expert . . . . .

Is a concave spokeshave designed to be used like any other? Or is the convex one designed specifically for smoothing or shaving hollows, like in the seat of a chair? Other than it not making pure straight lines of cut, any other differences using it like you’d use a straight one?

Actually it’s not flat but slightly curved along its length, but curved or straight the sharpening is done the same way. Also, yes, a curved spokeshave works the same way as the flat or straight ones. For chair seats we use more curved ones called travishers and inshaves. Though principally similar, and working them is the same too, they are meant for scalloped surfaces like seats and shallow bowls rather than flat or plane-like working.

That’s a nice description of sharpening these old style spokeshaves, thank you Paul. One thing I would add, is that is well worth putting the time and effort into carefully sharpening AND honing these to perfection, as I find they then stay sharp for much longer than the Stanley/Record type. I am forever having to re-sharpen those. Maybe the cast spokeshaves tempt heavier use? The wooden ones let you feel the grain and it’s more like stroking the wood into shape.

I have a nice collection now of the old wood spokeshaves, in different sizes and no two alike. They all feel different in use. Even very similar sized ones are different, and the blades are not interchangeable in any way. One I have re-mouthed with some sycamore (it’s what I had), but I haven’t yet got the angles quite right and it’s not as sweet to use as the others.

Hi Paul. I have a collection of these shaves in numerous sizes and have found that all of the irons fit over a normal oil stone, with the tangs on either side. My smallest size just fits over and when I find smaller, I will have to create some paddles.

The sharpening of these shaves is similar to that of a saw. Once you start you find that is much easier than you initially anticipated. With a little practice it becomes run of the mill stuff.

Thank you once again for a practical, achievable approach to working wood(and tools).

Regards

Actually, the issue for British made spokeshave blades is that they are often slightly curved along their length as in this case and so cannot be sharpened on a normal flat oilstone. The paddle takes care of this.

Paul it’s pretty amazing how through following your blog and watching your videos how much I have learnt and how much more there is yet still to learn! But confidence in my ability to sharpen and to just give things a go with hand tool working has been fantastic. The little nuggets of information are key. Again, thank you. M

That’s brilliant timing! Today I replaced a shed roof for my elderly father and found an old wooden spokeshave which I have now inherited. I was wondering how to sharpen it. Now I know.

Thanks for a brilliant blog!