different Views

It’s not unusual for people new to woodworking to be averse to taking risks as they develop their desire to work wood. The uncertainty of outcome feeds into our fear of any kind of failure and of course, we’re often involved with a material that generally presents us with an unpredictable outcome when we least expect it. Tools like saws sometimes seem to us to drift from the line we placed to leave us feeling unequal or worse still inadequate to the task. The wood rips and tears as we pursue the tasks of planing, chiseling and spokeshaving; operations key to a good outcome of our working. That surface we wanted to smooth so has torn terribly, as if, like hair, it was pulled out by its very roots. And then that ever so slight tilt into the cut line by a misaligned saw or chisel seems magnified a hundredfold when a partner piece meets the shoulder.

Tools, materials and our humanity must be synchronised continuously throughout the work we do and for extended periods of many many hours. If it’s been part of an artisan’s life for many decades it is as natural to him and her as breathing. In hand tool woodworking, the connection to the wood through the tools is incredibly high demand. You cannot allow distractions to cheat you of the prize you strive for by a less than positive grip, an unpredictable grain flaw, or an extra stroke that just overcuts too deeply. Once the wood is severed off accidentally, it simply cannot be put back, and though 50% of the time a patch might never show, the other 50% can and often does stand out like a bandaid on your face. The resultant gap in an off-square shoulder, even the very thinnest line, calls you a failure. Glue and sawdust, wood filler and such rarely ever leave you with a feeling of success but more a sick feeling. In some realms and by some, you would be considered the cheat.

Overcoming our fears and self-doubting is an important step in our developing the much-needed practical levels of working. I doubt that rote practice by repeating an hour’s worth of saw cuts and plane strokes rather than a few will be as valid as simply making a project and accepting miscuts that remain in the work as evidence of our learning curve. A chisel tray or silverware divider in a kitchen drawer will still hold together for a decade or even for a lifetime inside the kitchen drawer or on the benchtop. The vehicle for developing and delivering true skill is better achieved through using a project as a means to that end. Hence, in my classes, with 6,500 students through the three decades that I taught hands-on classes, relied on making three full-sized and substantive projects in steady and progressive succession after making only one of each of the kinds of joints needed in the upcoming projects. Newly gained confidences quickly translated into three finished projects of a decent size, replete with good joints and joinery throughout and the increase in confidence levels most students never thought they were capable of finding. What am I saying? I designed the projects for skill-building and the primary purpose in making them was to maximise learning so that the outcome was the skills you established and not the three projects. It’s great to make something that still has demands but ones that provide the opportunity to both learn and practice on.

Living with gaps in our early works records the steps and stages of our development. Through this, we can see where, when and how we grew when later we compare subsequent work with the earlier efforts. Of course, for many, gaps and other man-made defects can be a source of irritation rather than the developmental record I think to be important — I like evidence of improvement. Another issue surrounding a miscut is that it so pops off when we show others what we’ve made. That’s when the joke might come from someone as though they ‘caught you out. Instead of simply ignoring the cut, they just have to comment on the obvious, and the more the rest of the work nears perfection, the more the miscut stands out in contrast.

I think that it is very important to understand that a miscut joint line somewhere in the work is not a flawed you and neither is a flawed cut representative of who you are. These are not mirrors of who we are and especially is this so in the early stages of any learning. Indeed, flawed learning can be a result of the way we are or were channeled to think and do, and can just as easily be a product of flawed teaching, training and mentoring. . . and it might not!

But a gap can be a solid reference showing the best of our early ability as much as it can a mistaken cut and it is our option to accept it as no more than that. On the other hand, it can be a point at which we decide the best thing is and was to accept the gap but to then go on to replace the section with a good replacement piece of wood.

I look at expectations differently today than in years past. I’ve written on this before somewhere, but I might mention that one area of flawed thinking is to associate manual working like furniture making with levels of intelligence. I have known educators to say I don’t get it, I’m an intelligent man, how come I can’t get this to work right for me? Manual working can depend on many things not the least of which is whether you peeled potatoes for a family meal, whether you created order in your work ethic, or life was unchanneled buy guidance coming to you as a younger person. All crafts, no matter the craft type, are 95% or more about working to order with patterns and templates of working continuously being established as you grow.

I doubt that I have ever made a piece that didn’t have a gap somewhere or that I didn’t need to replace it. Would I fill a gap with a piece of infil to fill the gap. Well, let’s just look at that. Am I hiding flawed work, or am I creating an acceptable correction? Probably the latter. In the more exemplary pieces I once made there was a long gap along a groove housing a panel. It looked like a black line in a negative place. I sliced off a slither of wood beveled from zero to one-sixteenth of an inch over a distance of half an inch. The piece slipped in and self-tightened when halfway in. A slice with a knife took off the excess and the gap was completly gone. It was impossible to determine where the gap once was. In our world of making, there is no backspace and no delete button and neither can we just conjure up a replacement part using Sketchup. Would I throw out a good section of work because I have a gap of a paper-thin thickness? Most likely I would not. If the joint was compromised strengthwise, yes I would. I would never glue a component part to a chair component because of all furniture pieces used in life, the chair is subjected to the greatest rigours — I would never risk it.

I have trouble getting started, not just woodworking. Certainly for fear of failure, for fear of facing my cowardice in the face of difficulty. Afraid of the judgment that I am passing myself.

I struggle with mental health for the past few months, struggling to remember that my failures don’t define me.

I hope that woodworking will allow me to be at peace with myself and my defects, more acceptance toward failure & patience for growth.

Thank you for this text, thank you for reminding me that my flaws are not representative of me.

I was in the same boat as you. Yes it did at first affect my mental health but I have stuck with it and it’s actually become very therapeutic. I have old completed projects that haven’t stood the tests of time and elements but surprisingly I haven’t tried to fix them. Instead I just allow them to continue to fall apart so I can figure out what to do next time. Tried to tweak plans for a convertible picnic table/2 benches to where it was made out of 2x4s and hinges didn’t work out. Now we have 2 benches that have had plenty of use by family and friends. It will be worth it in the long run.

Alex, this is beautiful. Thank you for sharing, there are many including me who feel this same way. Therapy has been an absolutely life altering over the last 11 months and I would encourage you to take a step in that direction. My woodworking and shop time has been more plentiful and rewarding as a result. Much luck and love!

Just wanted to +1 Justin’s comment. Daily therapy, reduced fear about the work, reduced anxiety in general.

Alex, I, too, shared (past tense) the same inability to get started. It took a while for me to accept “good enough” in my woodworking. Fear of failure and a pursuit of perfection — which no one can consistently attain — were my biggest hurdles. As I’ve gained skill, more often I attain that perfect joint. But it’s no more defining of who I am than my slight errors. Hope you can allow yourself to get past judging yourself and can enjoy your journey.

Go for it! Take a simple project and study the plans ,yours or from a magazine ect. Decide your plan of construction one piece at a time and before you do anything ,visualize how it is going to fit with next piece,and the next and so on. Also by extra material for those really bad screw up. Try to have everything you need and be in a good frame of mind, not rushed tired or drunk. You will screw up. One of my mentors told me his mentor told him ‘don’t ever think you’ll be so good as to never s rew up, the important part is how you fix it. Good luck!

Paul’s Common Woodworking site has a tool tote project that is great for beginners. I didn’t need tool tote so made them to fit (altered dimensions) small Terracotta pots with flowers. Stained and flowers painted on sides. Made a bunch for presents and they were liked by everyone who got one. Point is there are good easy projects for beginners and Paul’s sites have many more to get your feet wet.

I bet your work is better than mine, Alex!

Facing the fear is a good way to grow.

Alex, it is just wood. Wood is easily replaced. I am a very experienced woodworker, and I still make mistakes. I have learned to fix those that need to be fixed, and accept minor imperfections as just that .. minor. We are always the ones to notice the non-perfect … and comment on it! No one else sees it. I believe that the mark of a professional is someone who has learned to fix mistakes.

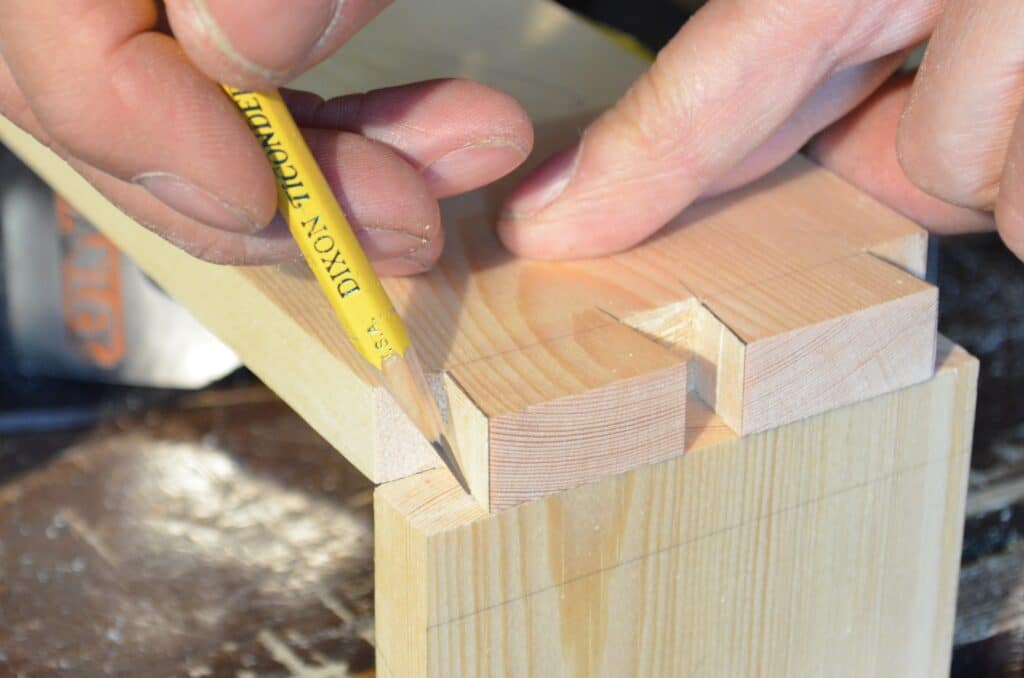

The other factor, which comes up in dovetailing, and other handcut joinery, is the need for a “go for it” mentality. Cut to the line and be damned! You will be rewarded with a fit off the saw. Cut away to be safe, and you will definitely need to make corrections. There is a greater chance of screwing up at this point. Just go for it. It is just wood.

Regards from Perth, Derek

You are so right Derek!

Paul posted pictures of joinery period pieces that have obviously withstood the test of time, in spite of their being “bad” when compared to what we are told to strive for by many web sites. Whenever I get the chance to examine period furniture I see similar joints. I would wager that if you were able to closely examine the work of many highly regarded craftsmen you would see a lot of imperfections. Surely this is part of the beauty of hand crafted joinery? The lack of absolute uniformity adds character.

Maybe we should just strive to make the next project better than the last, and realise that absolute perfection is not a realistic expectation.

We shouldn’t discount the time constraints in days past for craftsmen and women. I see woodworkers take an hour and maybe two to make a single half-lap dovetail make a corner to a drawer when these people might have had a fraction of the time and in some cases minutes. It was nothing for a man to have to dovetail six drawers front and back in a day and fit the drawers too.

and no doubt that repeated and constant practice, rife with error and accuracy under strict time pressure is what lead to the eventual effortless perfection that people achieve later in their careers.

You are so right Derek! My wife always says why do you always show me the minor flaws in finished pieces? No one else notices them!!

This is off subject Derek, but are you still maintaining your website?

Yes, the website is being maintained. I have not posted must recently – just too busy with my day job (child psychologist). I have a couple of articles to publish, and will do so soon. Regards from Perth, Derek

I find that the “fear of failure” comes from “actual past failures”. My pile of kindling with poor dovetail attempts cut in the ends attest to my past and continued failure at this task. Woodworking is supposed to be relaxing and invigorating. “Mount Dovetail” is in the way and will remain insurmountable.

Your mountain may seem to be a heap of failures, or it could be a mound of the most exquisitely shaped kindling.

In physics, we need to establish a zero point or a point of reference to be able to tell anything meaningful. Which way does galaxies spin? If you approach from the top, the galaxy spins clockwise. If you come in from the bottom, it spins counter-clockwise.

But what is up and what is down? Top and bottom?

The reference point you choose can make a whole galaxy spin the other way.

Choose wisely.

This is perhaps the most meaningful thing I’ve read in a very long time.

I was just doing a glue up of jewelry cabinets for a wedding present. I made five of them (3 for presents and 2 to sell). I had cut dados on the inside for a series of drawers, of various heights (small on top, larger drawers on bottom). Well, I found out I glued up two of the five with one side upside down – just wasn’t paying attention. No real way to reverse the glue up – so 2 of them just won’t work. I chalked it up to lesson learned, and just kept working on the 3 that could work. I’ll reuse the Cherry on something else at some point in the future.

Thanks Paul. Gaps in my work often frustrate me. I know that over time, if I am diligent in my work as you discussed they will little by little get better. The only way this can happen is to keep on making. Fortunately, my wife, is very kind hearted and just thrilled when we have a new piece of furniture in the home. As a artist herself (painting, clay, drawing, crafting, etc) I think she is more comfortable and understanding of these things.

The biggest challenge I face with remote learning and woodworking, is I don’t get to see other woodworkers in action and the errors they make in their work. Not that I want to gloat in their errors mind you. It would just help me understand it isn’t just me. Also, when I look at another person’s work I don’t see the errors initially. Rather, I see the beauty of the piece they have made. I am less critical as it were of their work than I am mine. This helps me to get a better perspective on my work. It looks fine. It’s the best I can make now. If I keep at it and am diligent it will get better.

Paul, Always enjoy the posts. I have an interest in building efficient clamping systems. The workbench has vices, dogs, and using jigs with those devices. Clamping pieces in odd angles for molding planes, working mullions, sashes and other pieces, how was that done in the old days. Any links to this subject you have touched on before? Thank you in advance

Most mouldings were made using a sticking board, a length of wood with a second piece screwed or nailed to it to form an ‘L’ shape. Usually, the base piece would be anywhere from an inch to one and a half inches thick and a few inches wide and this board would be the platform piece. The second piece is fixed to the back edge of the platform and the stick to be moulded or “stuck”, the “stick” buts up against it so that it stays put as you press the moulding plane into action. The term moulding or mould (molding and mold USA) was at one time called the stick or sticking. At the out-cut end, a screw or a block was used as a stop and either of these would sit below or outside the moulded area so that you could plane all the way through to make your moulding. If you have a lot of molding to make or it is a repeat work you need regularly then a sticking board may well prove worth keeping. If not, you can make one and dismantle it or simply do as the men I worked with and nail a stick along the benchtop, make your mould and remove the stop when done.

Timely post. I’ve been a bit hard on myself as I learn, seeing each gap and misaligned cut as a failure. I changed my perspective recently to see the work itself as a teacher. It clearly, concretely, and objectively points out each improvement that can be made with a gap, misalignment, and break. And hey, it often can be fixed, still holds, adds character, and as the works improve, they act as a journal of sorts.

For me, I really love being in my basement shop as a hobby, trying to learn hand work. I try not to have high expectations because its who I am. With that said though, I do try 100 percent to put together something nice. I just love the thrill of trying to cut dovetails by hand even though I have a router and a jig. It’s like playing golf. You adress the ball with expectations of a massive drive only to shank it into the woods in front of other golfers on the first tee. It happens. But for the love of the experience, let’s enjoy it. Don’t give up,keep trying.

Paul,

Many years ago I read an article about you and although I had very little “Hand woodworking experience”, I built a side table of beautiful 100 year old air dried walnut. Afterwards I made an under bench cabinet with dovetailed case and a dozen dovetailed drawers during which I learned more about the importance of sharpening than the actual layout which for me came naturally. I appreciate what you have accomplished and learn more from each post.

Thanks

I call it makers remorse, no matter how many times you look at the gap in a dovetail or an out of square shoulder line it just looks worse and worse. The thing is you know it’s there but usually 99 out of 100 people would probably not notice it. As Paul says if you have give it your all, dose it really matter. Was watching a tv programme the other night and a so called antiques expert was examining an object and he commented he loved the irregular pattern around this object because it ment it was hand made, not made in a jig with a machine.

I was about to say something similar… Most of the things I make are gifted to others. At first it was hard for me to sign my name to the pieces, especially when I look at them and see the flaws. But as I’ve aged, I’ve learned to recognize the flaws as proof that I made the piece and that it wasn’t something simply replicated by a factory machine.

A great piece, Paul, thanks again. May I share this with the makers’ space I’m in?

As a long time off and on Woodworker (going on 40 yrs) I’ve found staying focused is essential during all steps from layout to cutting to assembly and even application of the final finish. Sharp tools are paramount and I must thank you Paul for your many sharpening videos helping me to hone those skills. I encourage those that have not watched them to watch and practice Paul’s techniques. Having refined skills certainly helps but just as important is the ability to repair those woodworking opposies, hairline gaps and other road bumps that inevitably happen.

Usually other people don’t see the flaws.

My only regret is to have procrastinated too long before making my P.S. workbench.

Practice.

Look at a P.S. project several times before doing it.

Do it.

Look again, and you probably will see things you didn’t catch before.

Blog posts (including responses to comments) also contains plenty of informations which are not in the videos.

I was told something by a great woodworker that has helped me a lot. ” Remember the 6 foot and 6 inch rule. ” If it looks good from 6 ft it’s good. If someone has to get 6 inches from it to find the flaws you don’t need them for a friend anyway.

Thanks for this blog. I recognise the sentiments expressed by so many contributors most especially the sentiment of ‘If I don’t start I cannot fail’ I have a very simple show rack to complete which I need to complete the I am going for the big one – a bird feeder with dovetail joints. Like so many people I am filled with fear and trepidation at the thought of making a ‘porridge’ of it but as long as no one is hurt what could possibly go wrong?

The comments on mental health were well made as well. Making something with my hands is incredibly therapeutic.

Thank you Paul, stay safe.

Late comment.

Interestingly, on the picture labelled “Hmm . . .you tell me! Bit rugged?”, the bottom tail is only half a tail.

To allow for the groove behind it?

I didn’t look, Sylvain. Sorry! BTW. I am likely to be in Ghent for a few days. Are you near? I’m interested to meet my Belgian woodworking cousins for coffee!

Sorry I didn’t look for your response before today.

I am living in Brussels.

Maximum 49′ in train from Brussels to Ghent Station.

So you still have family there?

I do. My cousin and her children and grandchildren and then an Aunt in Roubaix.

I guess it is too late now.

I would have been honoured to meet you.

I first learned basic woodworking at school, so there were a few gaps in my joints. Later in life I taught myself how to restore antique furniture, albeit I have my limitations. In doing so I’ve seen the rough and ready that’s been around for over a hundred years but it has lasted despite the lack of skill when it was made. I’ve also seen some excellent cabinet making and likewise long lasting. It is a good way to learn about wood and how it moves and wears over the years. These days brown furniture can be purchased relatively cheaply through auctions and it is also a great source of well seasoned wood. I particularly enjoy restoring worn drawers, splicing new edges and replacing worn runners. There’s very little in the way of furniture that can’t be repaired, it’s always a good challenge and the results most satisfying. I’m always willing to learn and love to read these articles. Happy woodworking to one and all.

As I’ve mentioned previously, I spent 40+ years as a shoemaker. In the beginning I made many mistakes, but had a first teacher who taught me to laugh it off. Sure, he showed my the shoemaking equivalent of glue and sawdust, which I recall mastering before the pristine results began to appear with greater frequency. What also accumulated was a sense of mastery, a near-automatic comfort with the tools and machines, and a stronger ability to critique my technique as it unfolded.

Today, decades later, my knowledge is quite broad and have forgot none of the core and the high-level knowledge. But my hands are losing their touch, with a bit of shaking, and the steady progression of arthritis. Still, I have one student of sorts, and when I have to demonstrate something, am able to handle the impacts better than I expect to do.

Yet here I am, reading and watching you, Paul, and trying to learn, and practice with wood instead of leather now. My confidence in the knowledge is as good as I could expect for a relative newbie. But I still must contend with the failings of age, so I am more ready to accept the flaws, and keep moving forward.

I chalk that up to having such a fine teacher, as every student must do.

My dovetails have become much better over time. What has amazed me is how the size of gaps in earlier boxes have decreased. Some have disappeared. All were poplar.

Paul, This is such an encouraging article. I find it echos my process of learning, as I am very much a novice wood worker. At first I was foolishly expecting that I could achieve mastery on a first try. How self-defeating. When I shifted to seeing each project as a learning experience, accepting it as something I could enjoy for what it was. I found I became more relaxed and woodworking became more enjoyable. Thank you David York, PA USA

On a poorly-finished surface, the odd scratch goes unnoticed.

On a highly-polished surface, the slightest scratch stands out as a flaw.

The better your work, the more critically it will be appraised.

Thanks for this posting.

I was first interested in woodworking around 30 years ago. I was so afraid of making a mistake, I never got started! Your videos have inspired me to re-start and re-assess. So many times you have shown how you strive for perfection and take satisfaction in the trueness of a board. Doing your best is just that— not perfection, but your best. And that is enough.

Paul:

Once again wonderful post. This dilemma, suffered by many that care about the quality of their work, is common, and makes a statement about society as a whole. Woodworking, and life as a whole, is about the journey, not the destination. I have been reminded of this often, I guess I needed reminding.

Due to some physical changes, arthritis only being one, I take what you teach (tolerance as well as woodworking skills) and adapt it to me, personally.

As the old Nike commercial says, “Just Do It.” Don’t expect perfection, especially at first. Just build something you need or want. The next project, strive to do better (I bet you will, anyway). When you started driving were you perfect? I’ll bet you got better over time, and things you used to work hard to became much easier. Woodworking is much the same! When you start each day, determine the skills you will need to use, and do a few practice cuts, or chops, or whatever. No good athlete performs his best without first warming-up. Before long you’ll become better at those skills, but still warm up!

I switched from all power tools, to mostly hand tools. For a while, I had serious doubts about the switch, but I persevered. A while later something clicked (what I don’t know) and my skills took a Great Leap Forward. I’m no match for you, Paul, but I get better with each project (and I like to sign them, and date them, so I can track my progress). Am I a better woodworker? With each project, I earn new things, or a better way to do something.

Thank you, Paul, for encouraging us all to think, and for teaching us ways that are new to us (even if they have been around for years).