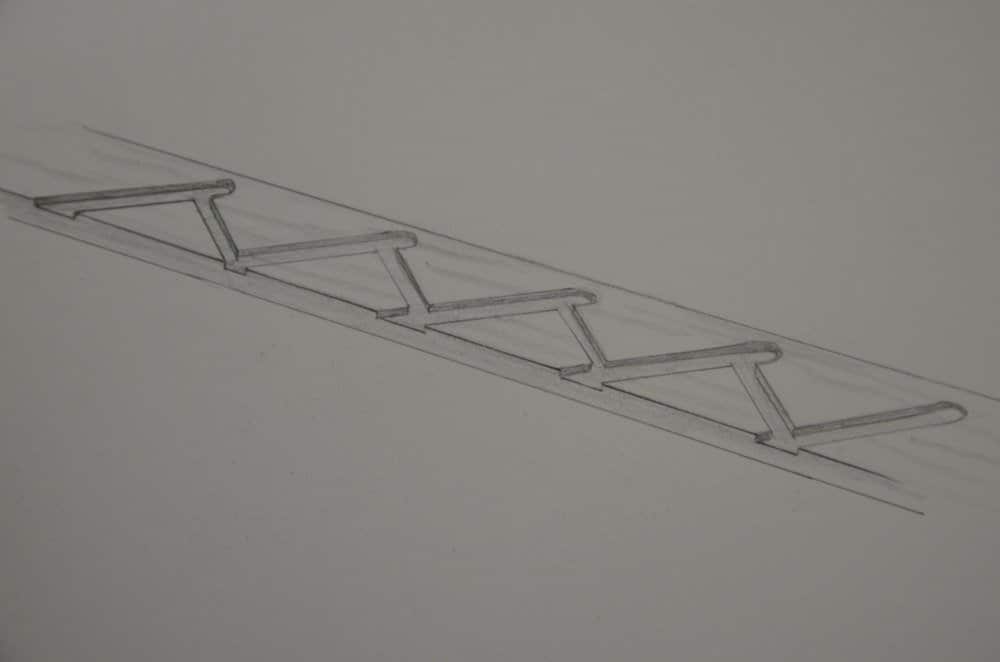

Added Schematic Drawing for Stanley #71 Router

Both modern-day makers of the router plane, Veritas and Lie Nielsen, sized their planes to the same or similar footprint of the Stanley #71 and Record 071 plane. Both makers omitted including the depth rod accessory and adjustable shoe for attaching to the arched front of the plane as in the early make of the plane prior to 1900. Obviously the original maker felt that there was an important enough need for this in the improved model so you may want to consider this when you are looking for a hand router. I have used both types without problems but I do like the depth gauge rod for different applications from time to time and also the ability to use the adjustable shoe for the edges of boards and such. Lie Nielsen offers a flat soled router plane and the split soled model emulating the Stanley version of the 71, but of course this means buying two models. Its easier to add the wooden sole and of course costs almost nothing whichever plane or maker type you buy. Having said that, there isn’t provision for screwing a wooden sole to the plane but I surmise that you could use the slot used for adjusting the fence. I would use cheese- or dome-head setscrews and thread the wooden board to do this.

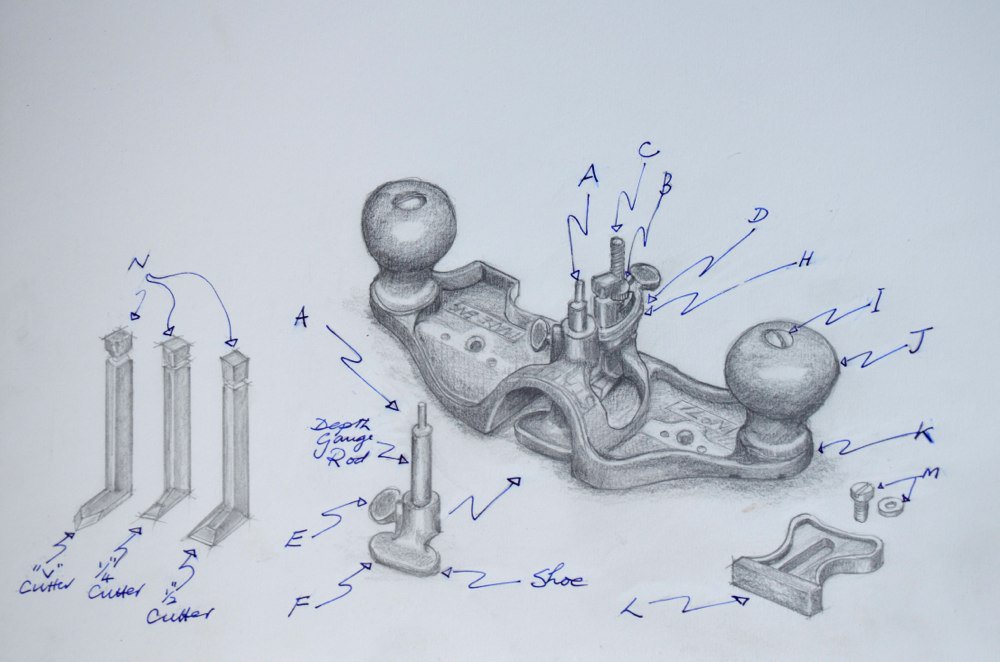

The repeat of the text from the Stanley #71 Router pamphlet from my previous blog yesterday is added because I reproduced a drawing with keys to identify the components parts to the plane.

Stanley router plane No 71

For surfacing the bottom of grooves or other depressions parallel to the surface of the work. There are many applications in pattern making, cabinet work and in fact almost all kinds if woodworking that call for these tools.They are particularly practical for routing dadoes for shelves, stair stringers or where pieces of hardware are to be recessed into the surface or edge of a board, such as large hinges or lock strikes, etc. It is not possible to show all these, but the user will discover places where the tools will prove their value.

CUTTERS-Cutters are made of high grade quality steel and are hardened and tempered. The shanks of the cutters are graduated in 1/16ths for 1″ which makes it possible to reverser for duplicate work and for approximate depth adjustments. Three cutters (N) are furnished, 1/4″ and 1/2″ router cutters and a (3 piece) “V” or smoothing cutter. Cutters are adjustable and depending on type of work can be held on front and back of cutter post (D) by means of clamp (H) and clamp thumbscrew (G).

VERTICAL ADJUSTMENT OF CUTTERS-To adjust cutter to desired depth, loosen thumbscrew (G), turn adjusting screw nut (B) up or down on adjusting screw (C), and tighten thumbscrew.

SHOE-A shoe (F) for closing the throat is provided for use on narrow work if a closed throat is practical and is fastened to depth gauge rod (A) by means of the shoe thumbscrew (E).

DEPTH GAUGE ROD-This rod (A), fastened by means of thumbscrew (O), may be used to control the depth of each cut, preventing the cutter from taking an excessive cut which would be inconvenient. For example, a cut 1/16″ deep can be cut repeatedly while still allowing the cutter to be set for the final depth of cut. One end of the rod is of small diameter for following in a small groove.

FENCE-An adjustable fence (L) is provided for use where the cutter is to run parallel to an edge. One side of the fence is designed for straight work while the other side is for curved work. Fence may be fastened to either left or right side of working face of plane bottom (K) by means of fence fastening screw and washer (M).

KNOB-The two hardwood knobs (J) are fastened to plane bottom by means of knob bolt and nut (I).

Schematic of Stanley #71 Router plane.

Router plane on wide housing.

The photo shows how to rout openings wider than the plane bottom (should read wider than half the plane bottom). The attachment of a flat board to the plane bottom is the simplest way to span large openings. The plane bottom is provided with screw holes for attaching such boards as necessary.

Here is shown a common job in home construction where this plane can be used – routing the stringer for the step and riser of a staircase. The other pictures show a stopped dado and a routed shape for an inset.

Is there any chance you might show us the sharpening technique for the router cutters? The back is easy, not so the front.

Thanks for all

Dave

There’s a blog in this somewhere in my archives.

Yes there is! Last section on this blog…

https://paulsellers.com/2012/11/buying-good-tools-cheap-the-router-plane/

Very interesting Paul and fabulous drawings! Many thanks for sharing all this with us.

Is there some secret to getting such a clean bottom with the router plane? A lot of my cuts are cross-grain and seem to leave rougher surfaces than what I’ve seen here.

Sharpness and making certain the cutter is indeed parallel to the sol . Put the cutter in the plane, level with the sole and rub once or twice on sharpening plate to highlife level on cutter lightly. Then sharpen to that line so it comes out parallel.

Hi Paul, I’ve sharpened my large rectangular blade up and it works a charm, with nice silky cuts! However, my cutter has never been parallel to the base (this plane was a new in the box antique). It appears to be in the bevel grind and I’ve gotten it more accurate by free hand sharpening but I’d really like to have it properly square in the bottom of the cut.

Do you have any tips for ensuring that the cutter and base are parallel? I have thought about using the router raised by a spacer over a stone but that would start a slight back bevel on the blade and I wouldn’t want to affect the performance of the blade to do it.

I just answered another with this Q.

Why don’t the images load on the pag on my iPad

Try checking your cache n cookies

I’m also having the same problem on both the iPad and the iPhone… Checked cookies and cleared cache no effect. Tried using the “Chrome” browser instead as well with no avail… If I click in the empty space where a picture would be though it will open the image on a window. Hope this helps!

I truly enjoy following your blog!

Cheers

Thank you sir, working fine here.

Thank you!

Sharpen by lapping the back then remove the burr by swiping the bevel on a strop (or smear some compound on the tip of your finger and use it as a strop). Don’t use to coarse a stone as it will, in time remove too much from the thickness of the blade.

But if you manage to chip the blade, then bad luck, you’ve got to do the bevel.

Paul I can’t seem to find the cutters for a hand router. I want to build one and I want to get a 1/4″W and a 1/2″ W cutting chisel. If you could guide me where to find them I’d greatly appreciate it.

Veritas sells their cutting irons individually and they fit the Stanley hand router planes too.

I have just purchased a Stanley# 71 Router plane.

It had not been used, there are no indications of wear.

The cutters engage the adjusting screw nut very tightly and it is not possible to to make a height adjustment.

Has it been required that when the plane is new the cutter slots need to be filed to ride smoothly on the adjusting screw nut flange?

Generally not, but Stanley UK has been in general decline because of its arrogance for over 50 years to date to my personal knowledge. A little fettling will get it going. They should have been ashamed producing products that left the factory like that bit they weren’t. Sad, sad day for Sheffield Stanley. Bad, bad day!

I recently bought brass Stanley 71 router plane with one 1/4 cutter with the same problem faced by David. I don’t know what year it was made. I want to buy the 1/2 Veritas cutter and check how this will fit with it, I think that most likely I will also have to refine with a file.

On the othe hand I saw that my router plane with Veritas tipe cutter it has one round slip and the adjusting nut scrape when I turn it and the clamp is not sit on the cutter post. But the original cutter has only one back side slip and it may be a little deeper. May be the adjusting nut press out the cutter a little and the back of cutter not fully takes its place. If so I need to file the slip. I don’t know which is the problem. I thought while I was writing I need to try on the cutter without the adjusting nut. And I will see which is the problem. Am I wrong?

Sorry for my English

Best regards

Hi,

Hope you can help, have just bought a Stanley router plane on eBay only to find the incorrect screws for the fence. What is the correct size and thread? I tried ringing customer service in the UK and emailing the states, about as much use as a chocolate fire guard.

Love your blog, you have inspired me to convert to hand tool working. Much more satisfying. Have just made three burger flippers, great result

I think if you contact Patrick at Superior tools he will answer this for you: http://www.supertool.com/StanleyBG/stan0a.html alternatively, they come up frequently on ebay.