An Interesting Point

This is my prototype, though it fully mirrors my final version to a tee. This one was finished last week but it stood there as a box for three weeks glued up, planed, sanded and finished with shellac. In preparing for a final rub down ready for waxing with furniture polish I noticed a slight step around the dovetail joints but what struck me was the inconsistency.

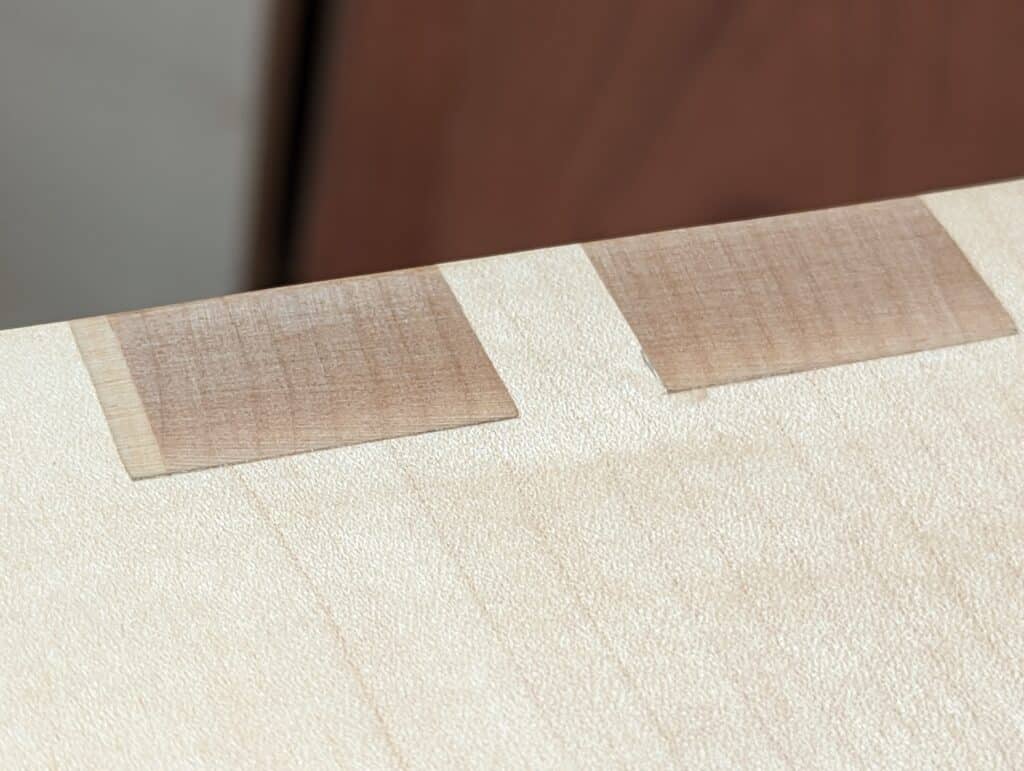

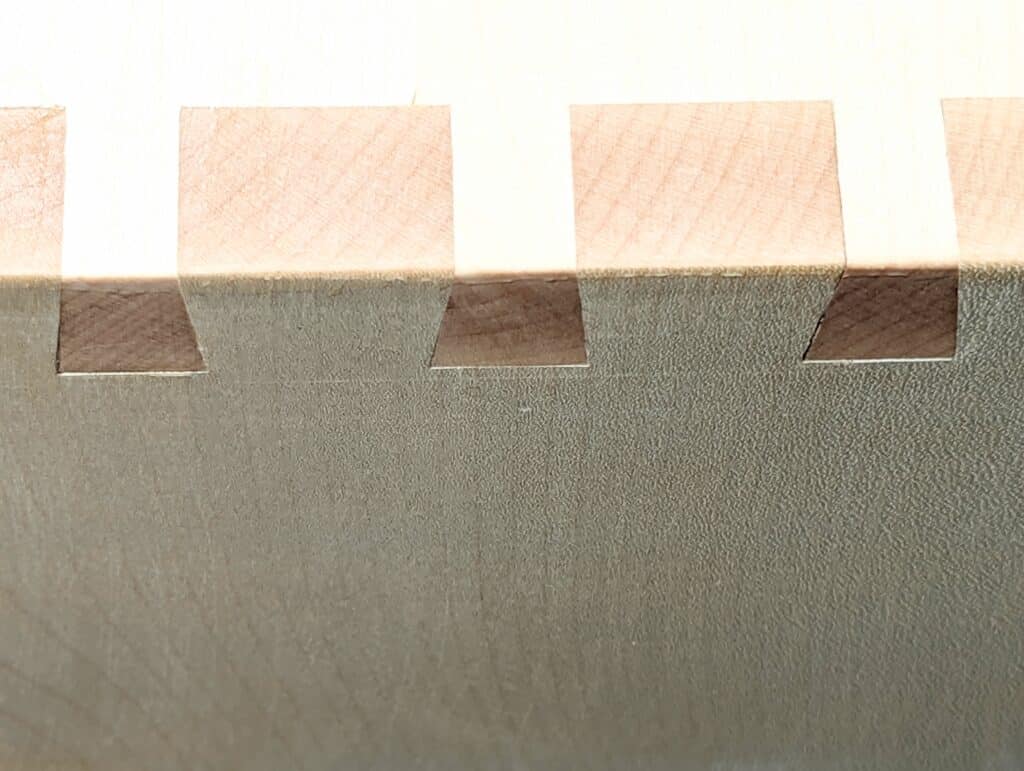

On this corner joint the tails and pins are imperceptible except by colour change. Trace your fingertips over both sides of the corner and it’s flawless. On the opposite corner on the same top but a different side but cut from the same plank as the opposite side with the slight step, I noticed the slightest sign of a step. Now I am talking the most minute difference: much less than a thin paper thickness: I worked the camera to get the fine-line shadow on the image.

But it was on the side where I noticed the larger more evident discrepancy. Again, the difference is but marginal — not as big as it looks in the enlarged image. My wood was acclimated and there was and is nothing I can or will do but this shows that some woods, though really constrained by a supremely strong and well-fitting mechanical joint combined with many square inches of interlocking surfaces, can and will still move with some wood types.

Such difference does not usually happen straight off but over a number of months or years in its final resting place or if a piece is placed near a source of heat or in a window where the sun shines through consistently. I would expect this if the piece was made in Houston, Texas and delivered to West Texas or phoenix in Arizona. Here in Britain, we don’t face the same extremes in humidity. A friend made a massive conference table once and inlaid the top with a 3/8″ deep by 3″ wide inlay aong and across the grain. He failed to calculate the rigidity of the mesquite and the fact that orienting it that way over three feet wide would be a contradiction in the non-shrink in the long grain of the mesquite to the cross-grain of the vintage longleaf pine. The call came in that there were several cracks along the tabletop resulting in him spending many days in West Texas repairing his work. In this case, the problem should have been obvious and should never have happened. The only time this could possibly be successful is in a building with guaranteed humidity levels, not something many can guarantee: museums and galleries, possibly!

Now in my case, I will live with this. There is a good chance that when placed in its final resting place the whole will release and absorb to an acceptable equilibrium and return to being flush one with the other. That’s more wishful thinking. I will live with it because it really is much less than it looks. In a year, when the wood is reacclimated to its surroundings, I could go back in and level the extremes. That’s doubtful though. I like wood to be wood. Let it live!

I often have this sort of conversation with customers and family. The wood is going to move – if you want something completely stable then have it made out of plastic. A good woodworker takes this into account in the build, but acknowledges that the wood is going to do what it wants.

I have seen the same on my dovetails. I have a block and rendered workshop with no insulation and watch the humidity rise and fall as the weather changes outside. The dovetailed pieces I make in winter, when I bring them back to the warmth and relatively low humidity of the house as finished articles, all end up like this after a couple of weeks. But as you rightly say let wood live.

Yes, same here. I actually like it, it’s a great way to know if the humidity has risen or fallen since making the piece. Especially if it keeps changing with changes of humidity. I had a small box here that was doing it, the timber fibres had shrunk, so it was opposite parts protruding to what you see in Paul’s photos above. On the case of shrinkage that stays that way it can be from the timber not being dry enough to start with and after I sanded the protruding pins flush again and refunished with Shellac I noticed years on that it had stopped moving. It’s good to observe these things, makes you think and I too am constantly explaining wiod movement to people who don’t know these things. Dovetails are a great indicator of what’s going on.

I have small box with a thin carved wood panel on the top. I moved from Sydney Australia in high humidity to Perth Western Australia with low humidity. The lid of the box curled up into the most amazing cylinder and I thought it was ruined. About a week later it relaxed back into perfect flat and has been like that ever since. Weird, but it’s wood…

I had this happen with a walnut cutting board. It went from flat, to a potato chip, to back to being flat.

I have exactly the same on a couple of drawer fronts in a cabinet I made for my garage last year… well seasoned apple used for the drawer fronts, with pine sides, had imperceptibly smooth half lap dovetails… 15 months later you can feel the lips… you can’t see them, but you can feel them.

I’m doing nothing about it.

Matt.

I’m sorry but I didn’t quite understand what was the problem with your friend’s table.

Can you please elaborate a little more and how could it be prevented?

Thanks

Wood shrinks across the grain by a massive percentage from wet to dry but shrinkage general only goes down for a period. If it kiln dried down to say 5% it is unlikely to go less and when placed in a normal environment the atmospheric moisture content may be high or low or anywhere in between. If the wood is dried and made into a project when the wood os say 12% the wood moisture content will increase according to the relative humidity in the surrounding atmosphere. The humidity say in Houston has a daily average of 75% whereas in El Paso it drops way down to 41%. If you make a table in Houston and it is made in an average shop conditions then when it arrives in El Paso because the humidity is so low,. the main body of wood will shrink and this could be as much as 6-8mm over a wide table. The mesquite inlay however will not shrink by any noticeable amount at all. The mesquite would do one of two things. if the main body wood of the table is strong enough it will cause the inlay mesquite to belly up in the middle along its length. That is very unlikely in the mesquite. Alternatively, the mesquite resisting the force would not stop the main body of wood from shrinking across its width so something would have to give. The main body wqood would then split somewhere.

To be honest with you Paul, that’s a minor defect, not one where I’d scream a complain about either as it’s hand made so adds character to the unit and the person who made it. Plus it would still outlast the mass produced crap on the maket today so there’s that.

I live in coastal Florida and work in the garage with the door wide open. I swear that poplar and oak dovetail boxes I made two years ago have lost the gaps they originally had. These are boxes that never came into the air conditioned main house.

Rarely seen this shrinkage in my longrain. Couple of herb plant boxes on kitchen windows sill have slightly protruding ends. It’s more the expansion across the thickness surrounding them than contraction on the length. (and vice versa).

The most common place I saw this was with thickness expansion around drawbore pins in my garage shelving racks.

Mr. Sellers,

The movement you show will almost always happen as wood is hydroscopic and is constantly absorbing and/or releasing moisture in relation to its environment. For dovetails in drawer sides this may lead to sticking during the “Wet” season, if there is one. Something easily solved with a few swipes of a hand plane. Where it becomes more of an esthetic problem is on outside surfaces like case sides and tops where there’s no molding to cover the joint. Another professional I also read didn’t like the look of them if they sank below the adjoining surface, so he decided the only way to effectively resolve this “Imperfection” was to intentionally cut the dovetails long by enough that he could chamfer their edges and leave them proud of the adjoining surface about an ⅛” or so. That does create a nice, even shadow line, but, of course, may not be suitable for all styles and designs.

Actually, that’s not the case at all. 99% of all the dovetails I have cut have shrunk quite evenly in one direction and not unequally where one part of the board shrank more and differently than another part so in a foot or two’s difference one part shrank while the other expanded. What happened in this piece was a highly unusual phenomenon which is why I wrote the article. Another thing is the reality that, yes, dovetails always show slight differences soon after finishing and planing flush, they are not constantly changing but simply find equilibrium to the surrounding atmosphere which here in the UK seems fairly constant to me as my box constructs rarely show any discrepancy and after a year or so seem settled and can barely be detected. I think, and it seems to me well understood that wood loses some of its ability to expand and contract by some degree. And you’re right, the chamfering of dovetail edges takes a some skill but also far too much time to get it exactly right, and it ends up looking quite unattractive, a feature I would never want, is something I would never advocate or suggest or teach as a creative solution primarily because it’s an almost useless application to real life, practical woodworking. So I really wouldn’t use it anyway and in the end my dovetails are now settled nicely, are all levelled out without reworking and looks really nice now that it is home. My point was it really didn’t matter, live with the outcomes and love it and don’t sweat about it. Wood is hygroscopic and readily moves but rarely compromises the integrity of the work you’ve done.