Marking Gauges

I’ve written about marking gauges from time to time. It’s a general term, marking gauge, and includes the various mortise gauges, combination gauges and the marking gauge singular with its lone pin. Through the years the single pin has generally been called the marking gauge and twin-pinned gauges with one fixed pin and the other adjustable partner nearby being referred to as the mortise gauge. These two names identify the two gauge types perfectly. The third marking gauge is referred to as the combination gauge because adding the third pin to the opposite side means you can own just one gauge and lower your initial outlay starting out. It was a great idea and you wonder why it took a hundred years to develop it. Or do you? Why shoot yourself in the foot when you can sell two gauges instead of just one?

I am sure today that I most likely own 50 different gauges. I have favourites and I have written on modern makers manufacturing them even to quite high standards. One or two Asian makers sell them under the banner Vintage Combination Gauge when they’ve been made brand new a month or so ago. Should you buy new or vintage? And then there are UK suppliers importing the same or similar gauges from Asia and selling them with insufficient information as to country of origin, calling into question the honesty of such outlets. In Britain’s recent history the country of origin had to be stated clearly on the package. Not so today. I have bought both new and old through the years, domestic versions and, well, imports. They all work just fine. Why 50 gauges? For my classes. 16 students, three gauges per bench space. Not greedy really!

Modern imports, new ones, always feel too angular and sharp-cornered for me. They need finessing to feel right in the hand, but that, to we woodworkers, is but a few minutes with a plane, a file and some 250-grit sandpaper. Once done it will feel as good as an old and well-used one. But this will not cost you less than buying a genuine vintage version anymore. Inflation is catching up on everyone it seems. What did cost £20 a month or two ago will likely cost you £30-35 with or without free shipping today. I must also say that something else has changed. A year ago I would have seen a hundred vintage combination gauges for sale on eBay, all between £10-14. Not so today. More like only a dozen worth looking at. I doubt that this will change in the future. Perhaps that is why the imported versions have gained in price — demand.

Considering this, I wanted to suggest the number of gauges you might look to own. In my projects, I seem to have projects that need a permanent setting to a couple of gauges where possible throughout a project — one setting might be essential for the mortise holes and another for the tenons. Tables very often have different distances from the outer faces. So too on some doors for whatever reason, not always but often enough. Another gauge setting delineates the thickness of stock you need to plane down to or saw to. Then there are the hinge recesses, flap width and depth, two different settings so two gauges, ideally. Of course, you can change settings and reset them for repeat markings later or elsewhere. As I said, ideally, keeping a gauge set throughout a project is always the best option.

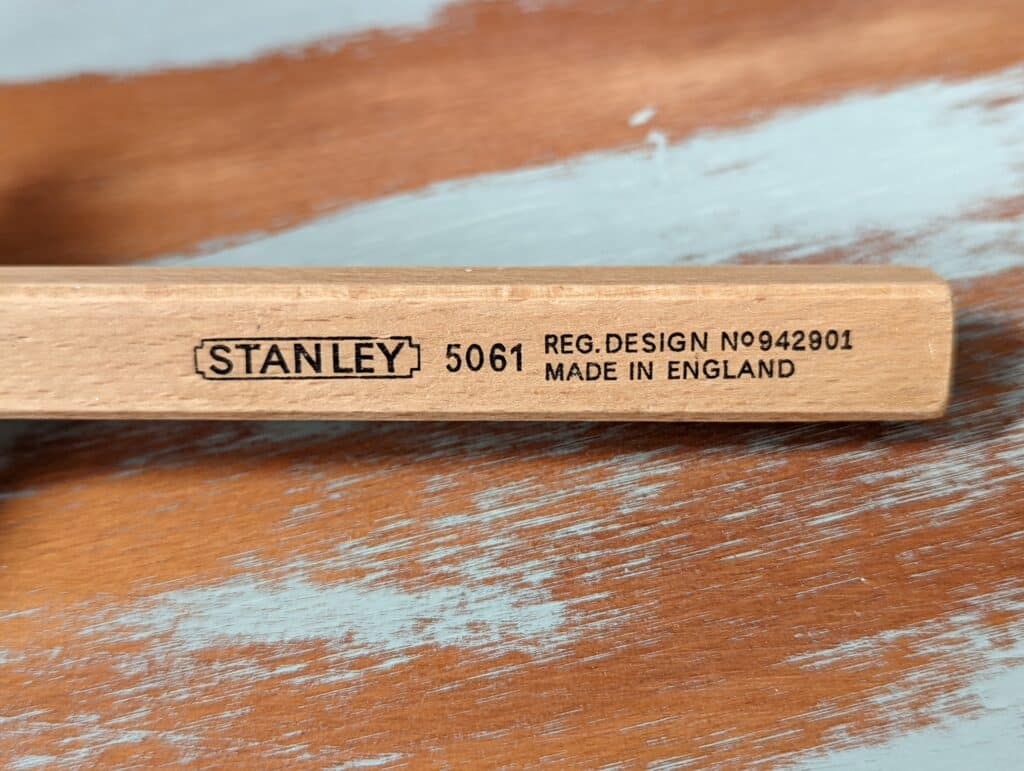

Which gauges you buy is up to you. The combination gauge is an uncompromising one-size-fits-all gauge. That said, most makers past and present avoided the nicer oval shape that fits the hand so pleasingly. The best more modern marking gauge was the Stanley 5061, a UK-made version that I have written of here. They no longer make them but they come up now and again on eBay. Here are a couple of blogs on how to convert an existing gauge to a 5061 type: https://paulsellers.com/2011/10/make-your-own-5061-style-gauge/

https://paulsellers.com/2011/10/make-your-own-1061-gauge-2/

I posted a video on YouTube here during the main lockdown UK when I made a few of my own videos because of isolation. The gauges were simple to make and perfectly functional and can be made from just about any scrap hardwoods you have in your waste bin. I was surprised by how popular the video was, 2.6m views to date.

As you can see, Stanley put some effort into their #5061 marking gauge. It suits the handhold perfectly, left or right.

But the gauge offers much more than a good fit. The pin is always in the most visible position and the trailing of the pin when marking means that the gauge faces the very least resistance.

It is the easiest of woodworking tasks to reshape lesser gauges to fit the hand as with the Stanley version. In one of the blog posts above, I show how the remove the pin and reinsert it from corner to corner as with the 5061. Even if you choose not to reshape the stock of the gauge, changing the pin position is a great improvement anyway.

Even though the hand can adapt to the more square profile of the blocky combination gauge, it is still left lacking when it comes to comfort. thankfully we use it for just a few minutes in a given day.

Hi Paul,

On some pictures above the beam seems to be loose in the stock. Do you confirm it is important to have them tight?

I bought recently a “vintage” Asian mortise gauge but it was so loose that I sent it back. If you changed the direction in using it, the beam moved in the stock, even after having tightened the screw. I ended by doing my own gauge but it is not perfect either.

I think it depends on the individual gauge. Mine all lock off perfectly well, even the ones that are old and happy. The good thing about the 5061, and yet another great feature, is clamping corner to corner it wouldn’t matter how big the gap was.

I have several pin types, but also use one that has a knife blade held in place with a brass wedge. Most of mine cost very little, often see them for £2-4.

The knife type is not really a marking gauge but a cutting or slitting gauage.

“The […] great feature, is clamping corner to corner; it wouldn’t matter how big the gap was.”

In my view this is the best feature.

Many gauges seems to be made without proper consideration to a good seating of the stem.

They come with one face of the stem rounded but the screw (or wedge) doesn’t push the stem against the rounded part of the hole in the body.

As if the rounding was for pin sliding/visibility alone or simply for aspect.

Hi Paul, noted you blog on marking gauges and I have about three or four regular and motice gauges. You did an episode on making gauges in 2020 and I actually folowed and made a set to match my chisels, I used Sapele for the body and stem with White Oak for the locking pin that I had left over. I then finished them with shelac and waxed them and have used them on mutiple occasions they work great.

Keep them in a box made from Sapele using your dovetail method, and finished the same way

Thanks for all your guidence

Philip Johnson

Cincinnati OH U.S.A

Never noticed the uncomfortable square design. Turns out I’ve been holding my marking gauge wrong!

Hi Paul,

Nice article, but I notice you didn’t mention the modern Veritas ‘disc-wheel’ marking/combination gauge (there are others, of course, of Asian origin) that some reviewers have raved over.

I bought one during Lockdown (mainly to cheer myself up) but I have to confess that I don’t get on with it. It works, of course, and I know that lots of people like them, but for me it lacks ‘feel’ and is too skinny to be comfortable. Perhaps you’ve covered this before, and I missed it. If so, my apologies.

It’s probably just me, but I’d like to know your feelings. I’m back to Grandad’s beech model with a bent shaft!

Regards,Chris

Mine “wanders” if marking with the grain. I will only use it for marking cross grain.

‘It‘ doesn’t wander, you allow it to wander. The art of craftsmanship is mastery of the materials and also of the tools. I’ve never heard of such a thing as a tool telling the master it’s not going to do something. Also, then how do you complete tasks that need long-grain gauge markings?

I guess these are more cutting gauges, too?

I don’t like that you can’t get a consistent depth of cut as you approach the limit of the cut (due to the circular cutter).

When you reach the end of the cut, stop sliding and then roll the blade. You can be very precise this way.

Sorry, Paul, I have just found a previous blog of yours covering the modern marking gauge, so please ignore my previous comment.

I agree that the modern gauge does not replace the traditional one, and, as you say, I’ve never broken a pin!

Iive dropped my old gauges many times, but my pal dropped his moder one just once, which broke the cutting-wheel!

Cheers,

Chris

If I’ve been out on a job and if for whatever reason only have one gauge and really could do with two or three to keep the settings I just use a scrap piece of wood and mark each of the settings on it as I’m using that setting for the first time and before adjusting to another setting .Not as good as having multiple gauges I suppose but at least there’s a permanent reminder to reset the gauge to .

Years ago I bought an antique mortise marking gauge ( some research on it shows it was made between 1848 and 1856) that has a small notch in it that allows you to recess the moveable pin so you can use just one of the pins for those times you only need to strike one line.

It seems like a more civilized solution then the “combination” gauges with three pins that always have one or two pins sticking up at you while you are using them.

That’s a cool. I can’t say I’ve ever found the unused pins on a combo gauge getting in my way, but it is a neat idea all the same.

Paul,

I have just been made aware of your assertion that marking gauge makers from Sheffield are importing tools made elsewhere, Asia.

Perhaps you would like to explain which manufacturers they are and on what basis you have made this assertion.

As a bit of an authority on this subject I can tell you this is simply not the case. The two remaining manufacturers of (amongst other things) gauges in Sheffield are Crown Hand Tools and Joseph Marples Ltd. I know this because, I am currently making a batch of Rosewood mortise gauges, soon to be followed by Beech & Walnut gauges.

Thank you for drawing this to my attention and you are right to do so. I should have said UK and referred to them as importers and distributors. I made a couple of changes.

Hello – I love gauges and I own about a dozen. I still use my Stanley 5061, which I bought about 45 years ago. It’s a good design, and it’s had a lot of use! I have also made a couple of gauges, with the pins in a corner-to-corner configuration, as described above by Paul. A few years ago I was given some well-used marking and mortice gauges, which had been used by my wife’s late grandfather. They, too, are still in use. I have found that all my gauges have benefitted from a degree of fettling. More recently, I have treated myself to a new screw-slide mortice gauge and a cutting gauge, both made by Joseph Marples Ltd, who, incidentally, have been manufacturing them in Sheffield for 200 years (and they are still doing so!). They’re not cheap, but they’re well made. Incidentally, I know that Crown Hand Tools Ltd also make their gauges in Sheffield.

I have had the 5061 for 50 years and it is very good. However, most of my marking is done with cutting gauges, which are kindlier to cross grain. Over the years viewing carpenters’ toolkits I’ve noticed more cutting gauges than marking gauges. My main use of marking gauges is establishing drilling holes equi-distant from sides.

I have had the 5061 for 50 years and it is very good. However, most of my “marking” is done with cutting gauges, which are kindlier to cross grain. Over the years viewing carpenters’ toolkits I’ve noticed more cutting gauges than marking gauges. My main use of marking gauges is establishing drilling holes equi-distant from sides.

Couldn’t find a way for a new post but just had to add what’s already been said. I’ve also had my Stanley 5061 for some 45 years, bought, incidentally from Buck & Ryan, Tottenham Court Road, London – at the time probably the finest ‘tool shop’ in the UK.

My 5061 has seen a lot of use over the years but an close inspection yesterday reveals it’s still as good as new. I’m particularly impressed that once the thumbscrew is tightened the stock remains rock solid and the needle point shows no sign of wear or bluntness.

It was also good to read that it’s still possible to buy new, UK-made, gauges. And it also shows that good design and manufacturing excellence never goes out of fashion.

Mike

Very good now on

Paul, is the marking gage you used in the recent 3 part candle box project a vintage one or is it one that is presently be manufactured ? If so could you give information on ordering it . Thank You

It’s a design of my own and made by myself, Geoffrey.